Measuring device of ring rolling machine

A technology of measuring device and ring rolling machine, used in length measuring device, metal processing equipment, metal rolling, etc., can solve the problems of uncompact axial size and difficult to realize deep hole processing technology, so as to reduce maintenance workload, The effect of measuring the correct size and reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

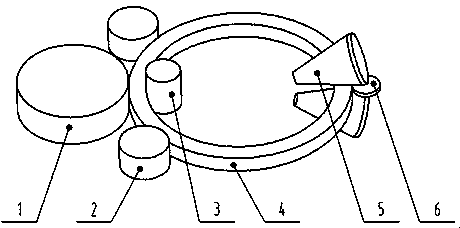

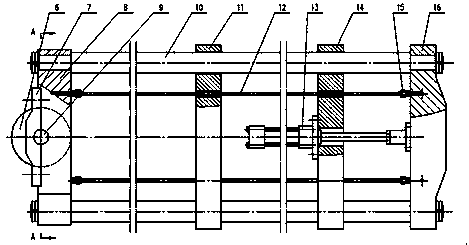

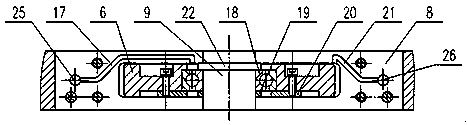

[0010] Such as figure 2 As shown, a measuring device for a ring rolling machine includes a fixed seat fixed on the frame of the ring rolling machine, and the fixed seat includes a front fixed seat 11 and a rear fixed seat 14 . The guide rod 10 slidingly matched with the front fixed seat 11 and the rear fixed seat 14, the front beam 8 and the rear beam 16 arranged at both ends of the guide rod 10, the measuring wheel 6 arranged on the front beam 8, and the front beam 8 is provided with accommodating The groove of the measuring wheel 6 and the rear half axle hole that is arranged on the both sides of the groove for installing the fixed shaft 9 of the measuring wheel; there is also a front cover 7 fixed on the front beam 8, such as Figure 4 As shown, the front cover 7 is provided with a through hole 24 for the measurement wheel 6 to pass through and is arranged on the front half shaft hole 23 for installing the measurement wheel fixed shaft 9 on both sides of the through hole 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com