rigid core

A rigid core and core technology, applied to tires, other household appliances, household appliances, etc., can solve problems such as difficult implementation, achieve efficient assembly, high precision and stable assembly, and prevent positional deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, embodiments of the present invention will be described in detail.

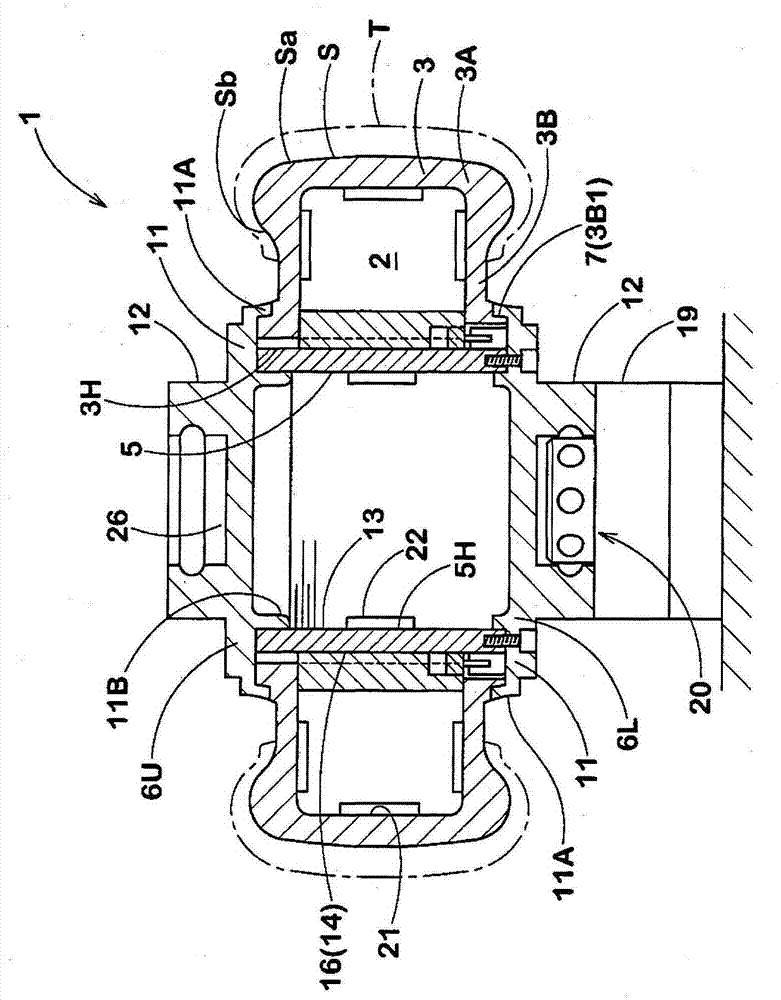

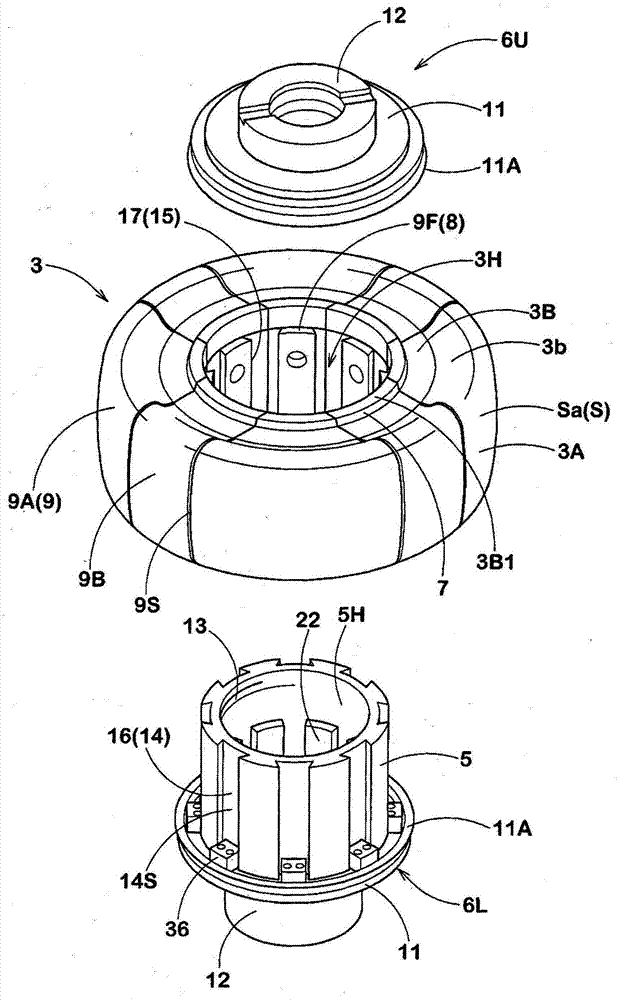

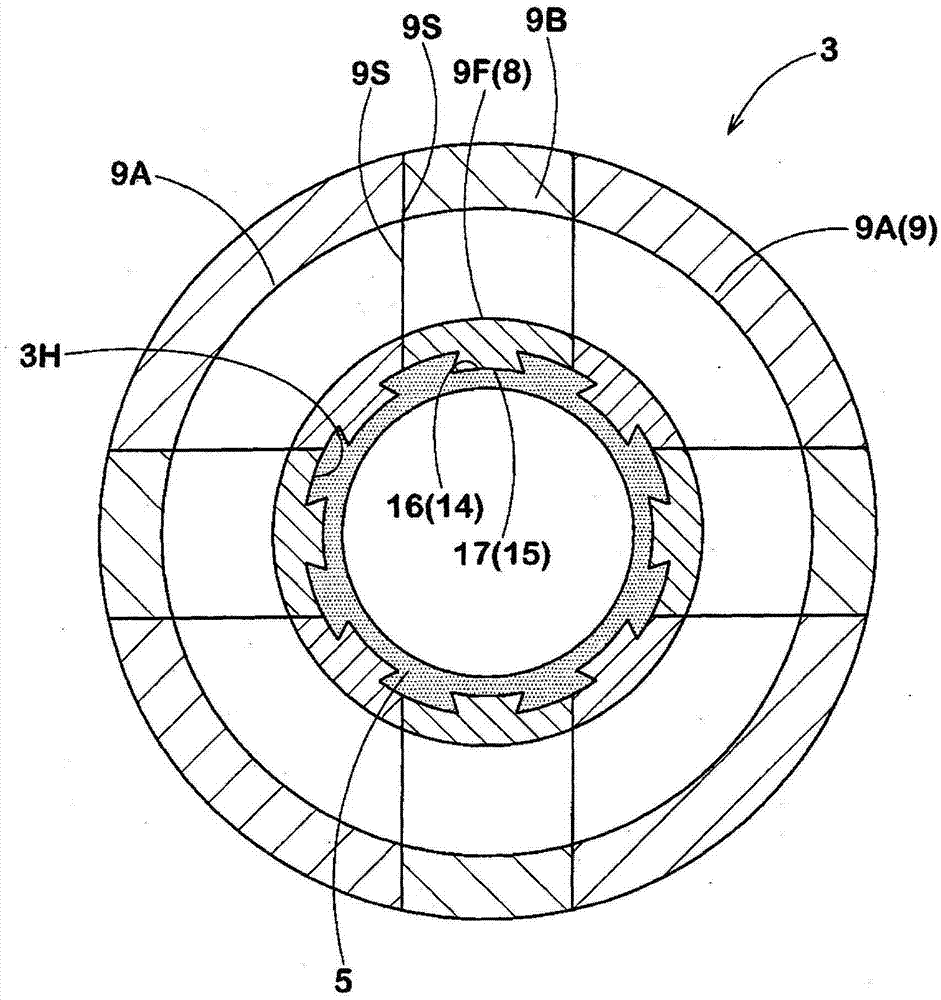

[0035] Such as figure 1 , 2 As shown, the rigid core 1 of the present embodiment has a hollow annular core body 3 having a tire molding surface S on the outer surface.

[0036] Then, a green tire T is formed by sequentially pasting tire components such as an inner liner, a carcass ply, a belt ply, a sidewall rubber, and a tread rubber on the above-mentioned tire molding surface S, and the green tire T is combined with Rigid core 1 is put into vulcanization mold 50 ( Figure 9 shows a part thereof), the green tire T is heated and vulcanized in cooperation with the vulcanization mold 50 described above. In addition, the tire molding surface S includes a tread molding surface Sa forming the tread inner surface of the raw tire T, and a sidewall molding surface Sb forming the sidewall inner surface and the bead inner surface of the green tire T. It is roughly consistent with the shape of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com