Overturning type skip bucket and dump rail thereof

A flipping and skipping technology, which is applied in transportation and packaging, lifting equipment in mines, etc., can solve the problems of safety hazards and easy broken ropes, and achieve the effect of smooth flipping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the examples, and the purpose is only to better understand the content of the present invention. Therefore, the examples given do not limit the protection scope of the present invention.

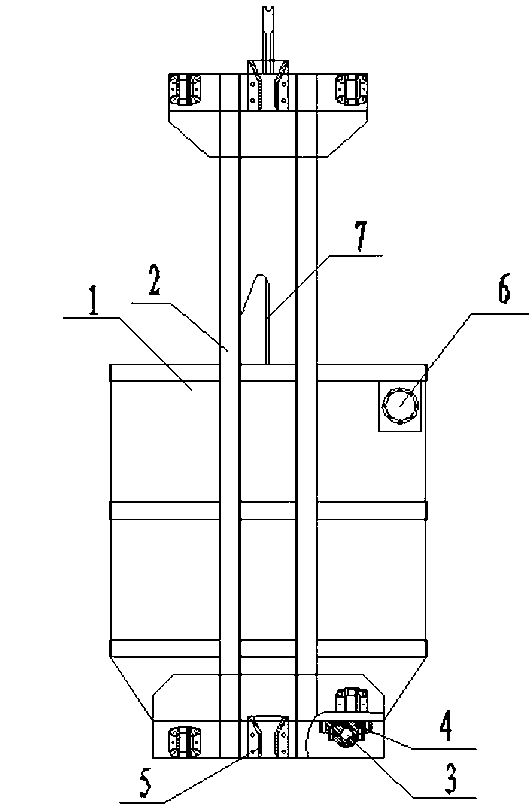

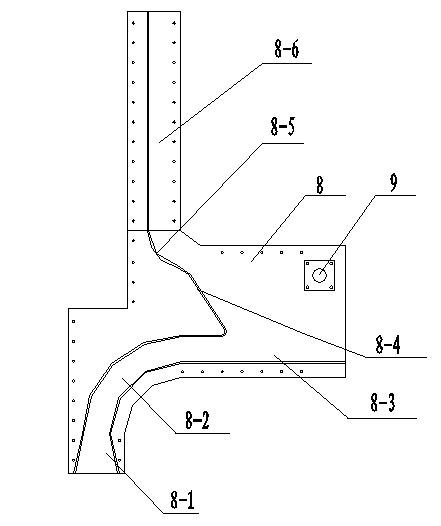

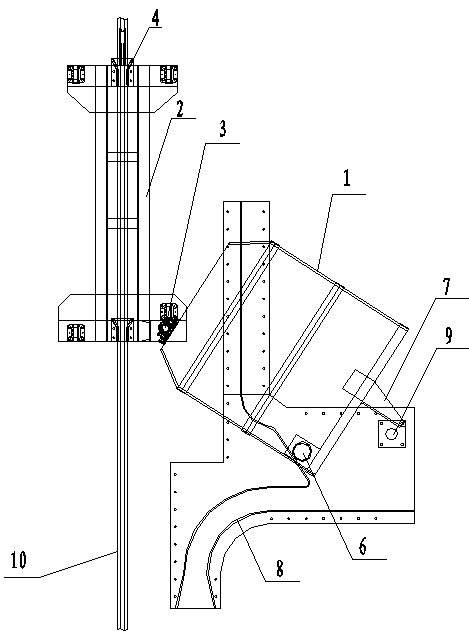

[0013] see figure 1 , the skip assembly consists of a skip 1, a skip frame 2, a rotating shaft 3, a shaft seat 4, a limit slide 5, an unloading wheel 6, and a bracket 7, and a rotating shaft 3 is installed at the bottom of the skip 1, and the two ends of the rotating shaft 3 It is fixed on the skip frame 2 and connected to the bottom of the skip 1 through two shaft seats 4. The skip 1 is flatly seated in the skip frame 2 and can rotate around the rotating shaft 3; the upper part of the skip 1 is installed two Unloading wheel 6, a support 7 is respectively installed on two side plate tops of skip bucket 1, is used for assisting skip bucket 1 to turn over along curved track. The upper and lower ends of the skip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com