Manufactured-sand water-washing device and technique

A technology of water washing device and machine-made sand, applied in the field of sand washing device, can solve the problems of reducing work efficiency, large amount of sand returning, affecting output, etc., and achieves the effects of improving production efficiency, avoiding maintenance, and eliminating production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

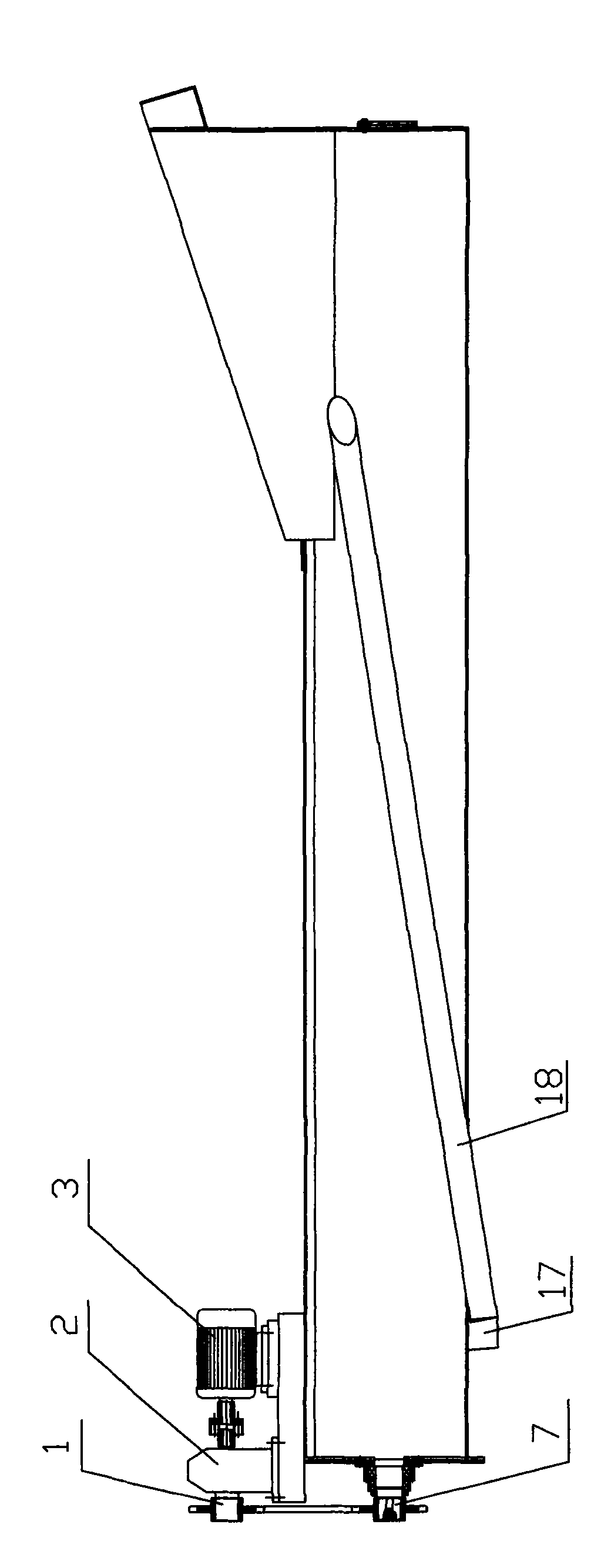

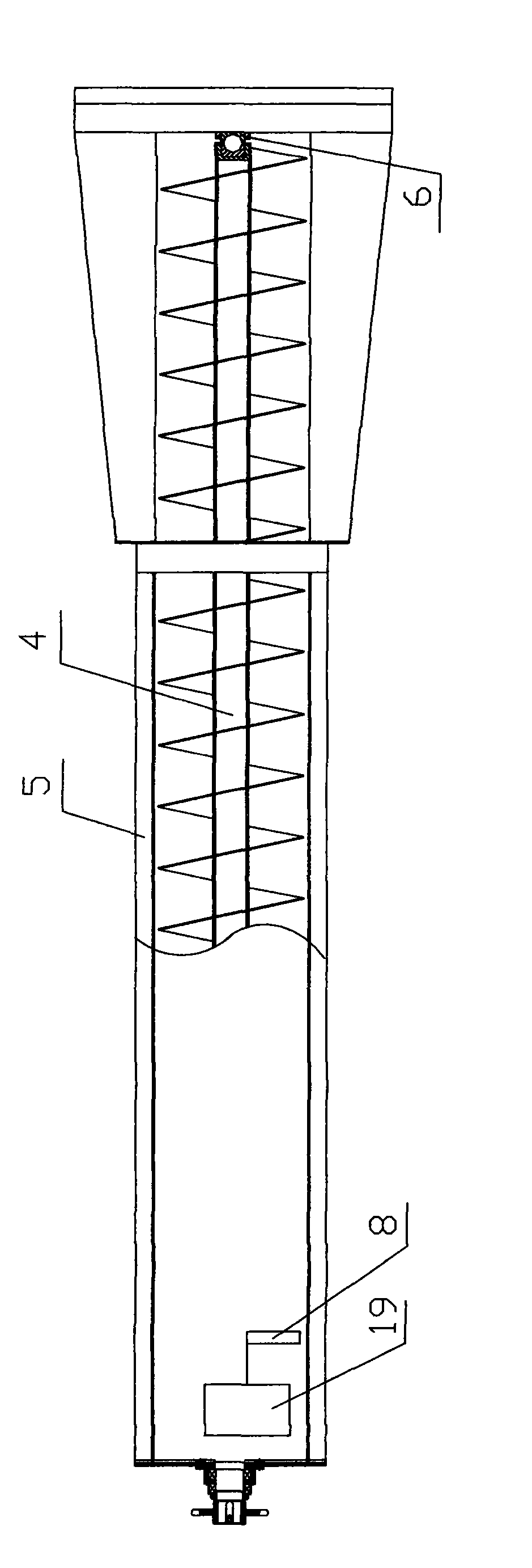

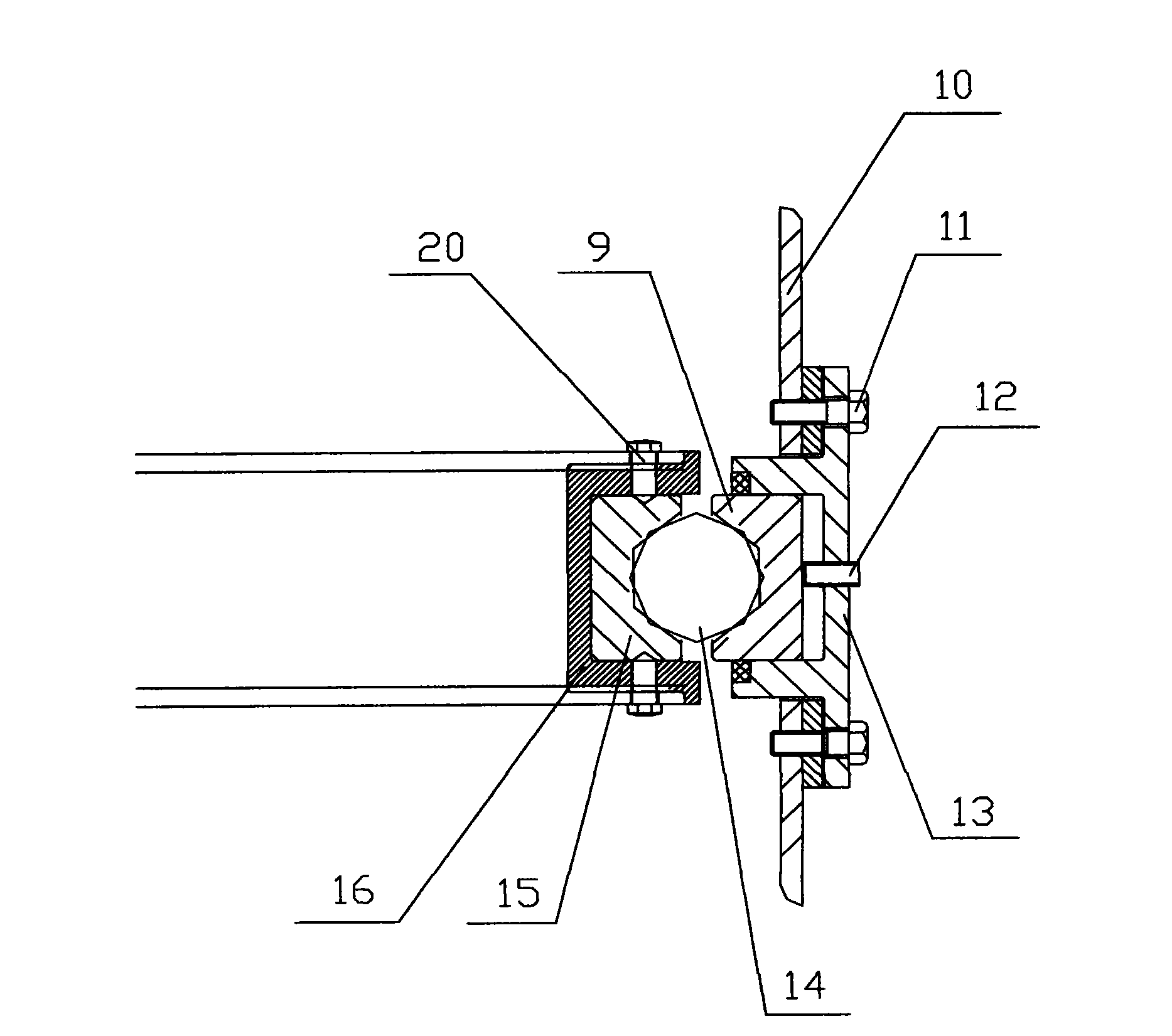

[0034] A water washing device for machine-made sand, including four sand washing machines and a fine sand collector, the sand washing machine includes a transmission device, a housing 5 and a spindle system fixed in the housing 5, the housing 5 The front end is provided with a discharge port 19, and the rear end of the housing 5 is a sand washing tank, and the upper part of the sand washing tank is provided with a slurry discharge port; the slurry discharge port of the sand washing machine is connected with the fine sand The inlet of the collector is connected; the fine sand collector includes a sand dredging pump, a mortar thickener, a high-efficiency dewatering screen, a storage box and a return box. The end of the discharge port 19 away from the front end of the housing 5 is provided with a water return port 8, and the water return port 8 is connected to one end of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com