Die clamping bolt and tube pile forming die comprising die clamping bolt

A molding die and bolt technology, applied in the direction of screws, molds, connecting components, etc., can solve the problems of high manufacturing cost, slow speed, failure of mold closing or mold opening, etc., and achieve the effects of improving service life, reliable matching, and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

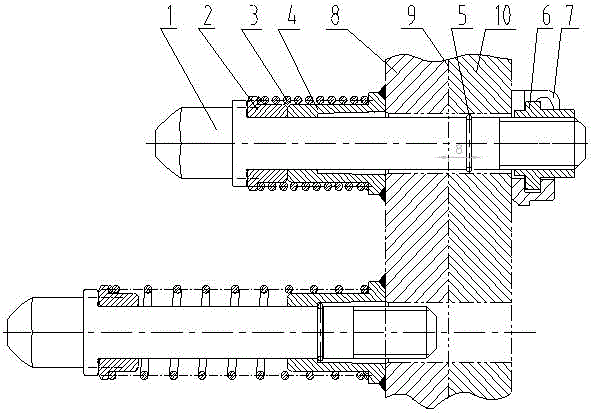

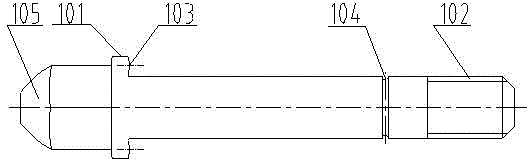

[0019] Example 1: refer to the attached Figure 1-8 . A clamping bolt, the upper part of the clamping bolt rod 1 is provided with a circle of bosses 101, the lower part of the clamping bolt rod 1 is covered with a thread 102, the flange-type movable spring seat 2 and the flange inner ring boss-type fixed spring seat 4 are sleeved. A spring 3 is sleeved on the clamping bolt rod 1 and the flange-type movable spring seat 2 and the sleeve wall of the flange inner ring boss-type fixed spring seat 4, and one end of the spring 3 is connected to the flange-type movable spring seat 2 flange ring wall. In contact, the other end is in contact with the flange ring wall of the flange inner ring boss-type fixed spring seat 4, the lower part of the clamping bolt rod 1 has a ring slot 104 and is located on the upper part of the screw 102, and the shaft steel wire retaining ring 5 is stuck in On the card groove, the shaft wire retaining ring 5 protrudes on the surface of the clamping bolt rod...

Embodiment 2

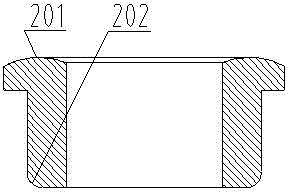

[0020] Embodiment 2: On the basis of Embodiment 1, a matching structure of a clamping bolt and a pipe pile forming die, including a pipe pile forming die (8, 10), a flange inner ring boss in the clamping bolt to fix the spring seat The chamfered surface 401 of the flange ring in 4 is welded with the upper die 8 in the pipe pile forming die, and the spring 3 is sleeved on the flange type movable spring seat 2 and the flange inner ring boss type fixed spring seat 4 sleeve wall , and then the clamping bolt rod 1 passes through the flange-type movable spring seat 2, the flange inner ring boss-type fixed spring seat 4 and the die edge of the pipe pile forming mold (8, 10), and the upper boss 101 of the clamping bolt rod 1 is connected to The flange ring in the flanged movable spring seat 2 is in contact, and the shaft steel wire retaining ring 5 is clamped on the groove of the lower part of the clamping bolt rod 1 and is in the fixed sleeve of the flange inner ring convex table fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com