Flat coaxial cable and fabricating method thereof

A technology of coaxial cable and manufacturing method, which is applied in the field of flat coaxial cable and its manufacturing, can solve problems such as unfavorable thinning of electronic products, and achieve the effect of reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

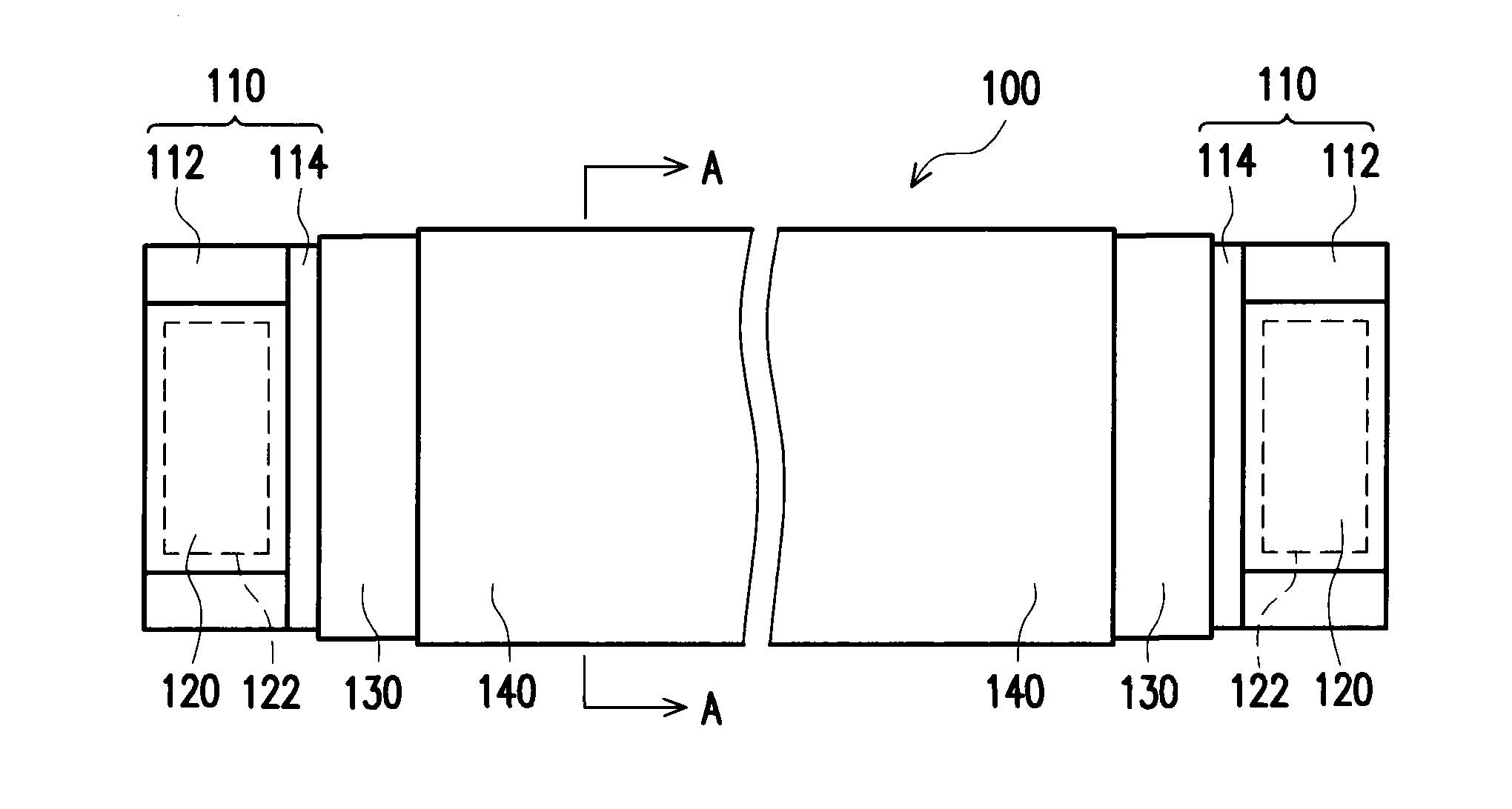

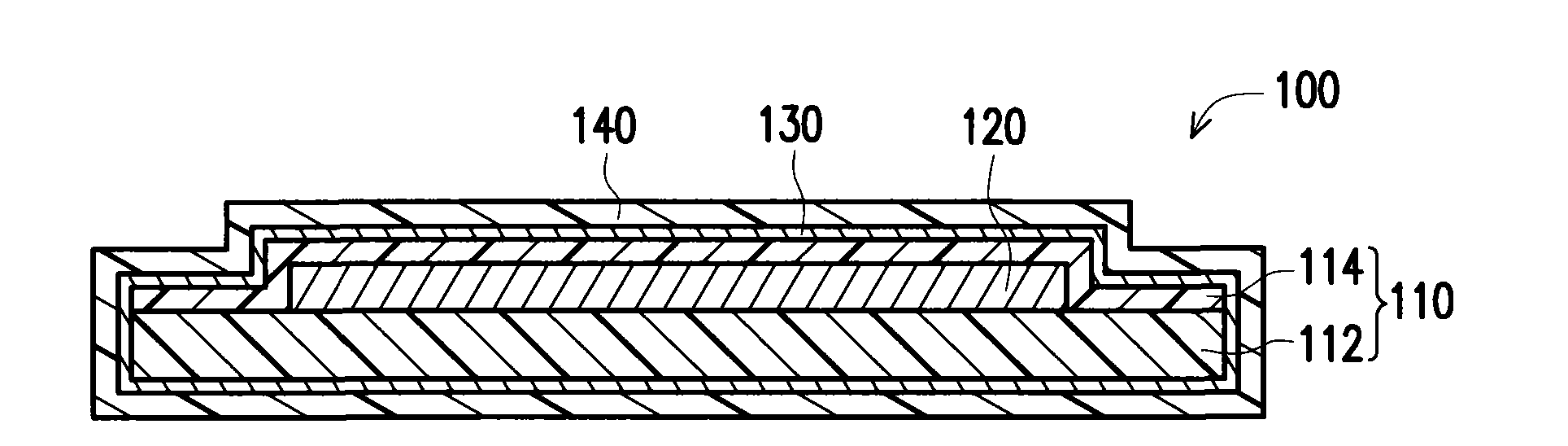

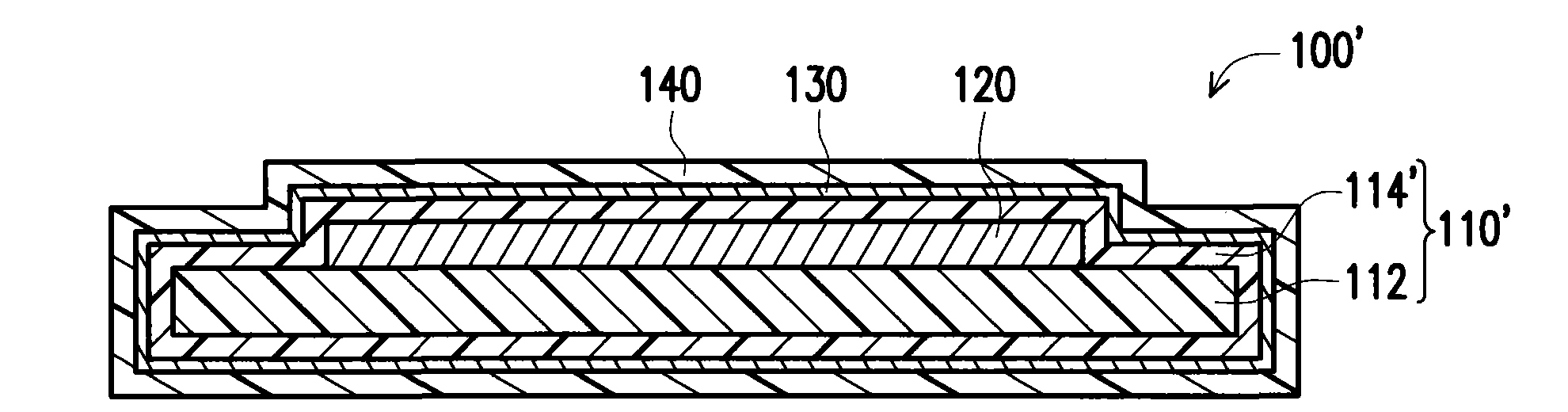

[0027] figure 1 is a top view of a flat coaxial cable according to an embodiment of the present invention, and figure 2 for figure 1 An enlarged cross-sectional view of a flat coaxial cable along line A-A. Please refer to figure 1 and figure 2 , the flat coaxial cable 100 includes an insulating base layer 112 . In this embodiment, the material of the insulating base layer 112 can be a soft polymer, such as PI, PET or PC with insulation, good dielectric strength (insulation withstand voltage strength) and chemical resistance.

[0028] The flat coaxial cable 100 of this embodiment further includes a conductor circuit layer 120 , and the conductor circuit layer 120 is disposed on the insulating base layer 112 . In this embodiment, the material of the conductor circuit layer 120 may be gold, silver or copper. The width of the conductor circuit layer 120 may be 0.5 cm to 2 cm, and the thickness of the conductor circuit layer 120 may be 50 micrometers to 200 micrometers. Di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com