Power supply device capable of rapidly wiring

A power supply device and fast technology, applied in the direction of busbar/circuit layout, clamping/spring connection, etc., can solve the problems of hidden safety hazards, lack of protection, time consumption, etc., to achieve reliable compression, avoid accidental fall off, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

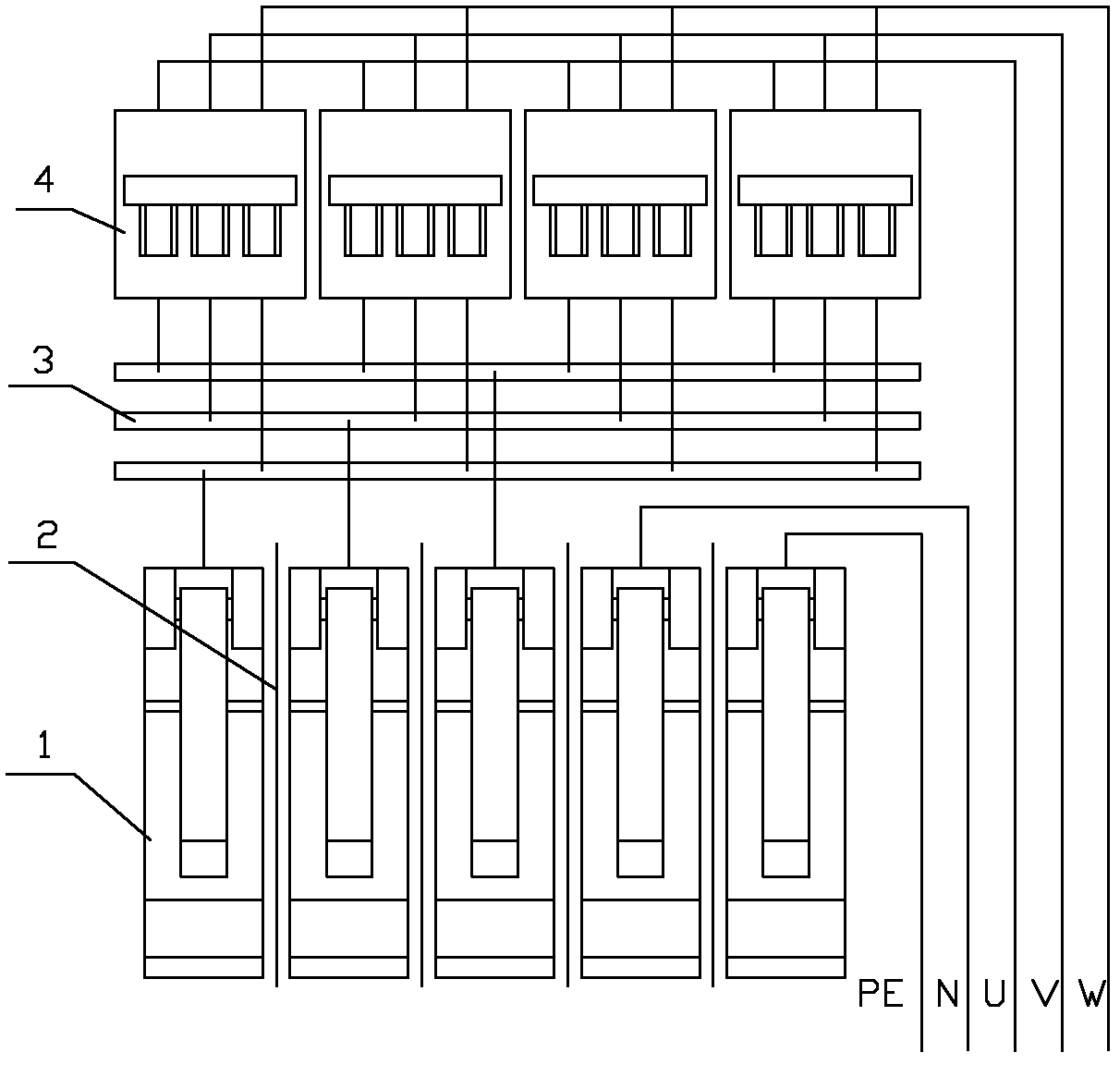

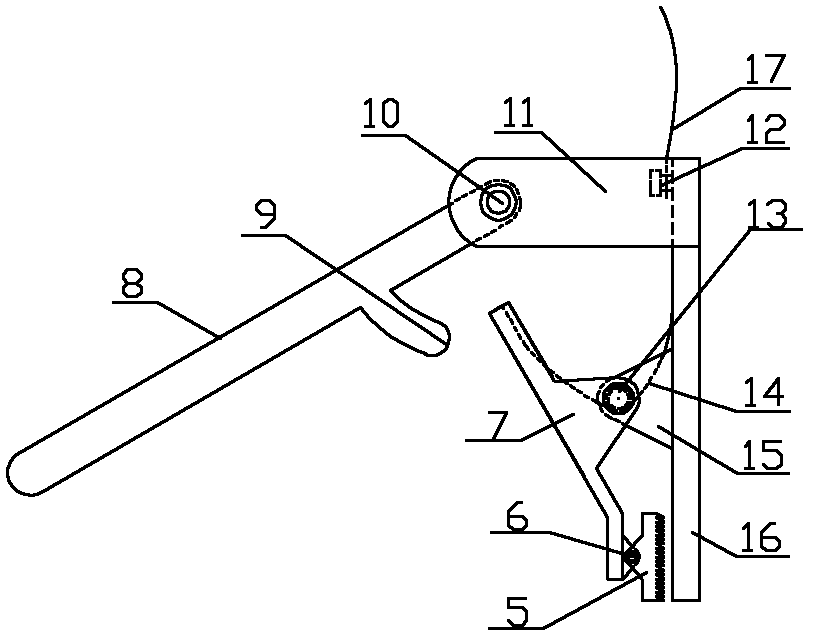

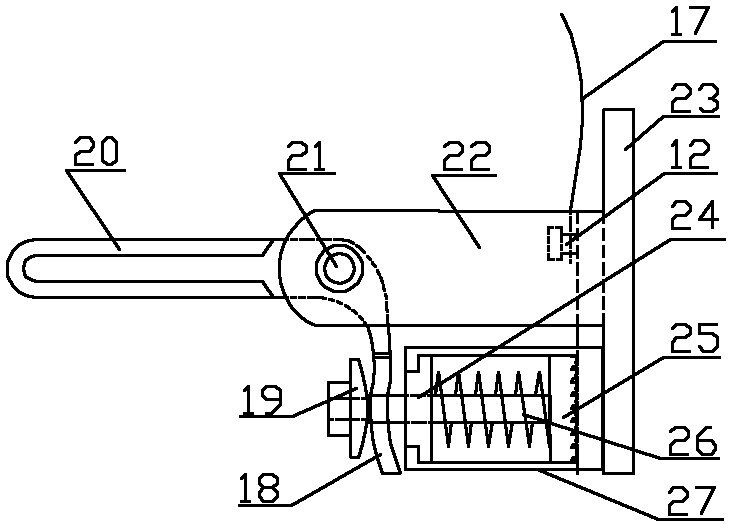

[0022] As can be seen from the accompanying drawings, the quick wiring power supply device of the present invention is mainly composed of a quick connector 1, a copper busbar 3 and an automatic switch 4, and the quick connector 1, the copper busbar 3 and the automatic switch 4 are all installed in the power box. The capacities of the four automatic switches 4 are respectively 10A, 25A, 36A and 100A. One end of the four parallel automatic switches 4 is connected to the three-phase power supply U, V, W, and the other end is respectively connected to three copper busbars 3, responsible for supplying power to the three copper busbars 3. An insulating plate 2 is provided between the five quick connectors 1 to enhance the insulation performance; among them, there are two quick connectors 1 on the right side, one of which is connected to the ground wire PE, and the other is connected to the neutral wire N. The other three quick connectors 1 are separately connected to the three coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com