Method and loom for producing woven fabrics having added weft effects

A technology of adding wefts and looms, applied to looms, textiles, embossing, etc., can solve problems such as hindering weft insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

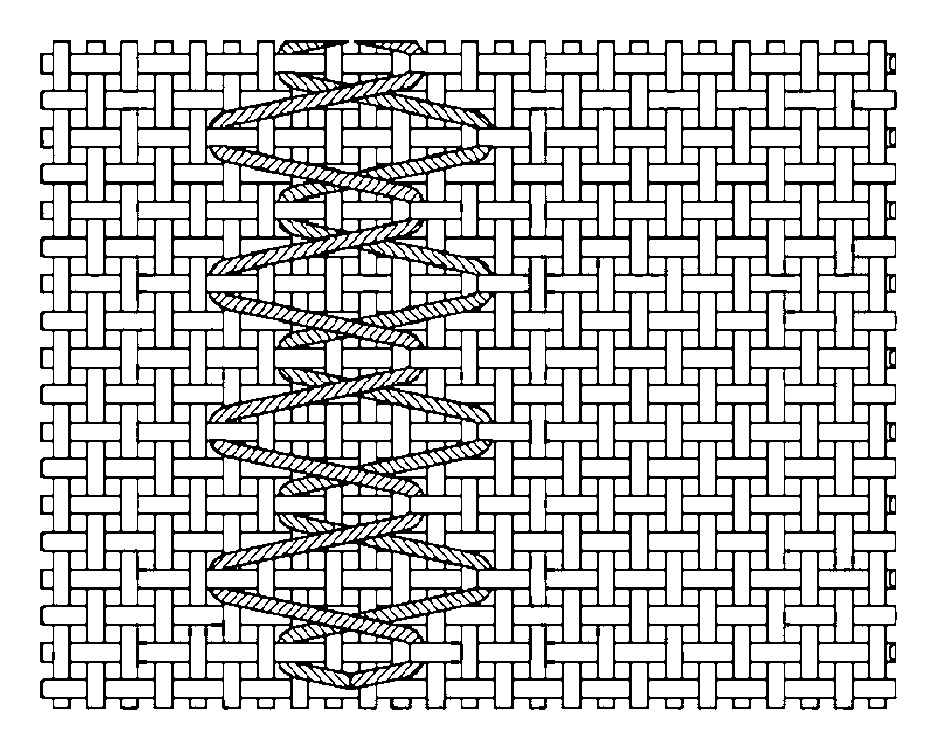

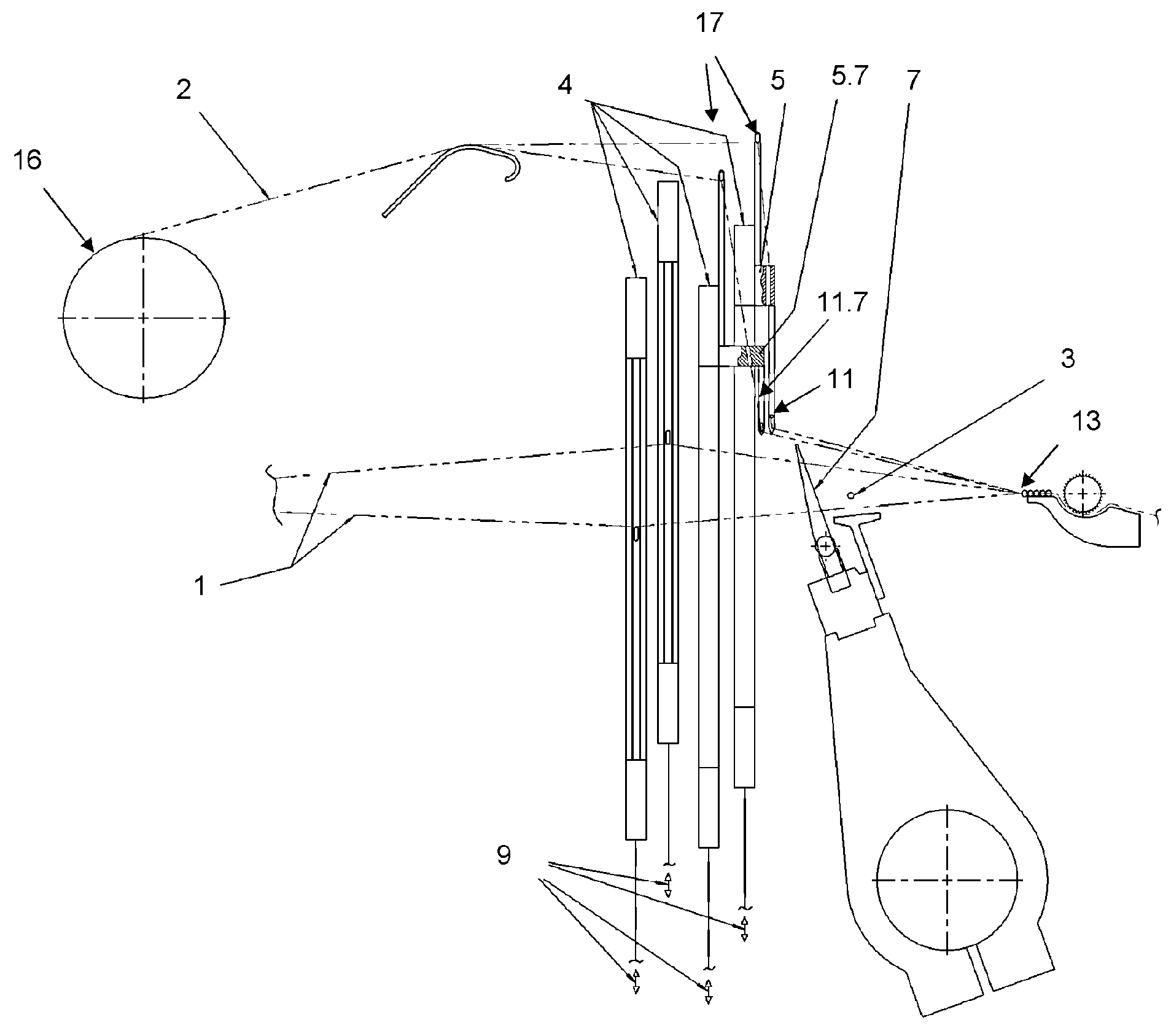

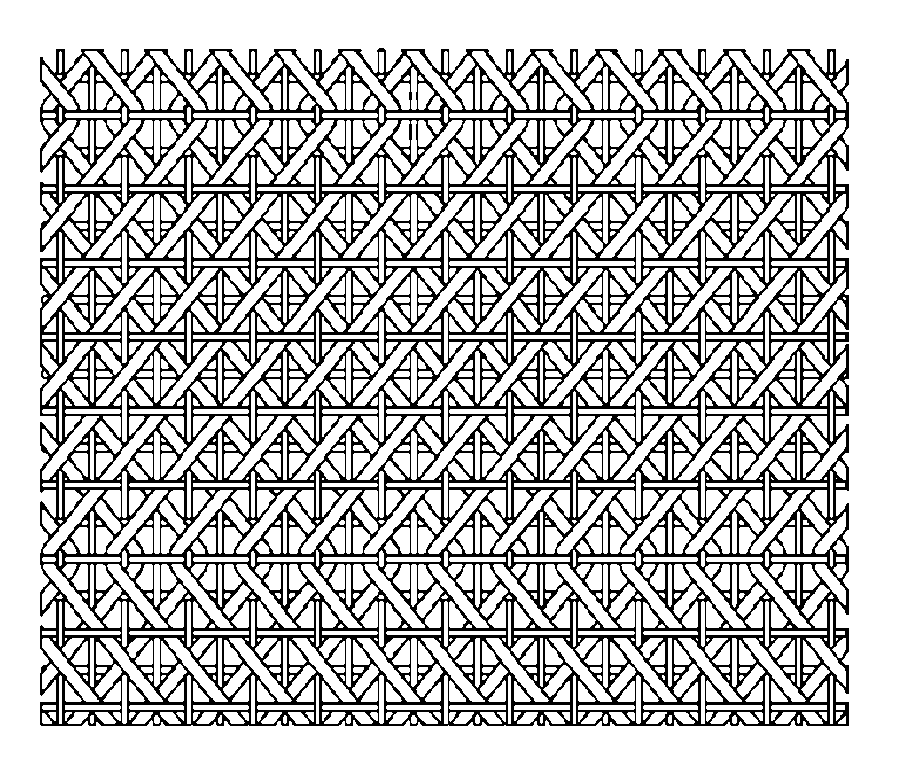

[0063] Figure 1a , b and 2 show in partial views a loom with a shedding drive 9 for driving the shedding element 4 through its vertical movement to form the sheds 1.1, 1.2 limited by the warp threads 1 . A shedding drive 9 known to the expert per se can consist, for example, of a set of rods and rods, which is arranged below the shedding element 4 and which transmits to the shedding element 4 the drive movement of a shedding machine, not shown, arranged outside the machine frame. However, any other electromechanical, hydraulic or pneumatic device can also be used as opening drive 9 .

[0064] The shedding element 4 is formed in the present example by a known heald frame with healds, through whose eyes the warp threads 1 are guided. Furthermore, there are also devices known to experts for picking the weft thread 3 in the weft thread direction 12 into the sheds 1.1, 1.2. This can be a device for mechanical weft insertion by means of a weaving shuttle or gripper or a device for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com