Method and apparatus of operating scanning probe microscope

A scanning probe and microscope technology, applied in the field of scanning probe microscopy, can solve the problems of time-consuming, unresolved dynamic characteristics of AFM imaging, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

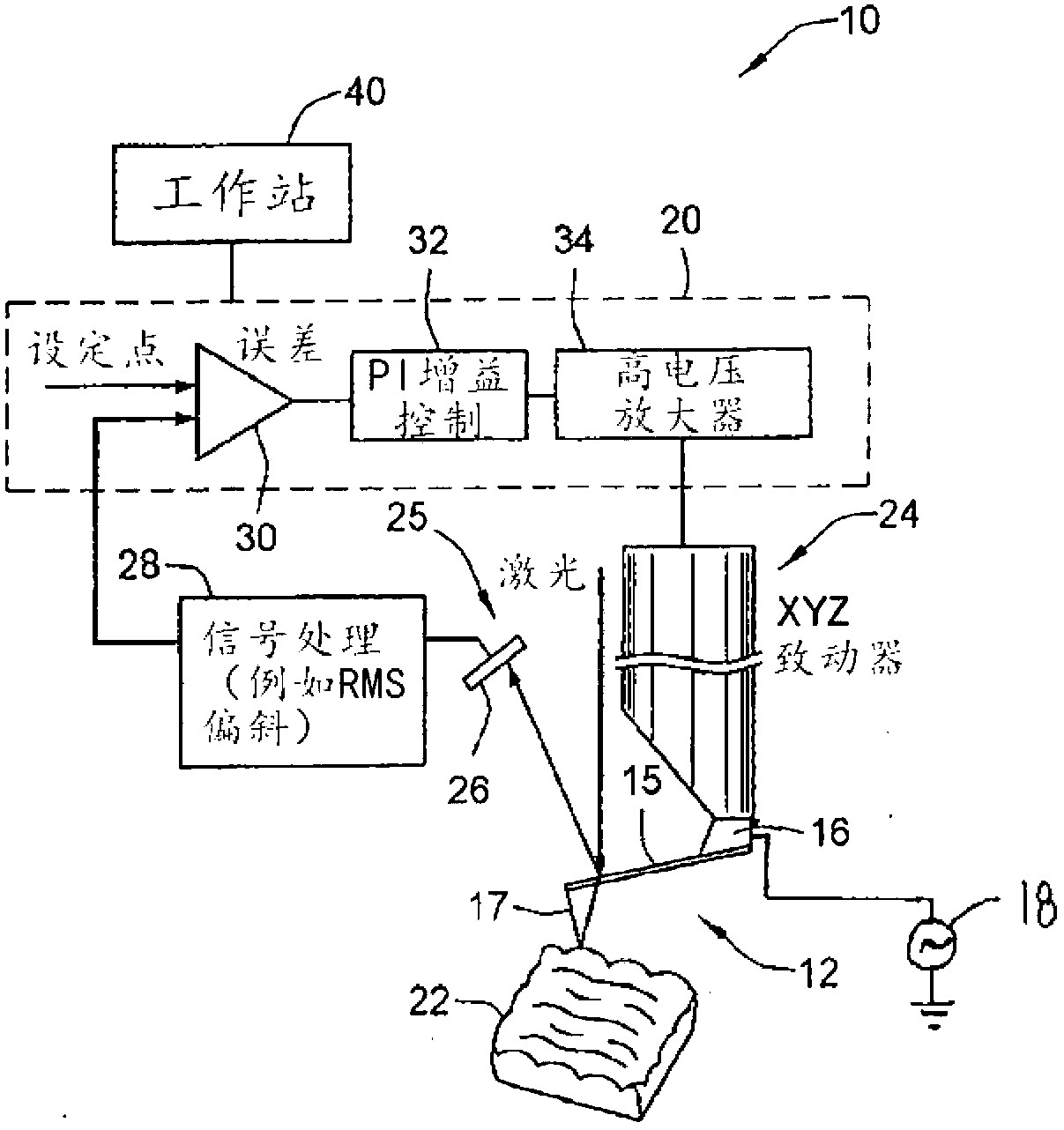

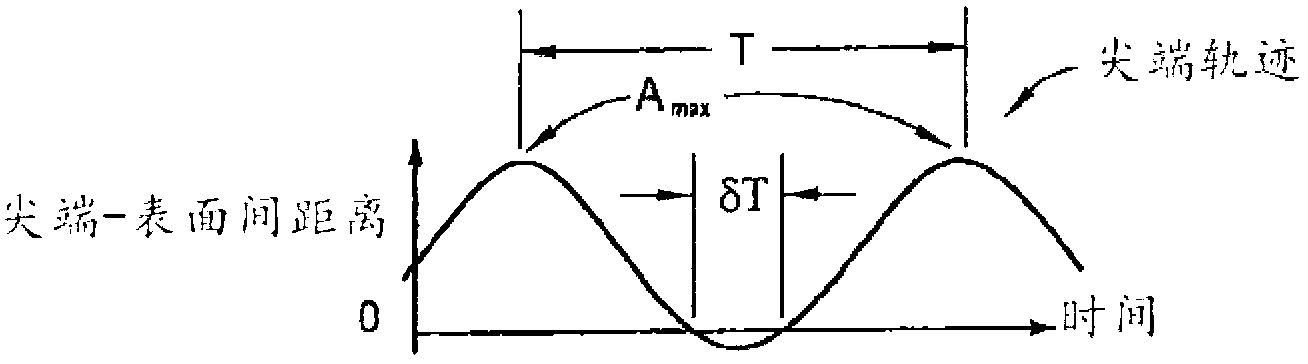

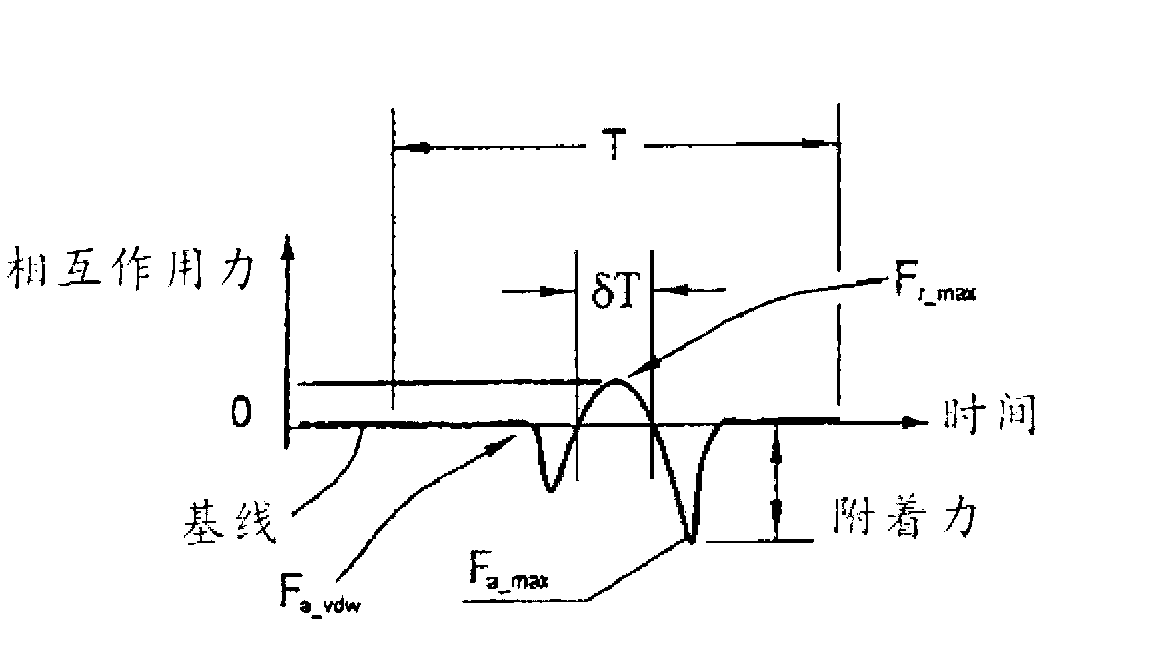

[0116] Embodiments are directed to the Peak Force Tapping (PFT) mode of AFM operation, where the interaction force between the probe (tip) and the sample is monitored and used to control the tip-sample separation at very low forces and without Loss of scanning speed. The technique described herein provides high resolution by keeping probe tip-sample forces low and enables essentially real-time property mapping of the sample surface. Preferred embodiments are inherently stable and thus facilitate long-term force control while maintaining the ability to capture high integrity data (increased resolution). Also, unlike traditional TappingMode, since no tuning is required TM Like AFM, AFM setup is faster and easier than with other AFM modes. The key concepts driving the PFT mode are graphically illustrated and discussed herein.

[0117] In practice, there are three main problems to be solved before AFM using instantaneous interaction forces can be realized. These issues are: 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com