Foreign material blowing structure on automatic soldering device

An automatic welding and driving structure technology, applied in auxiliary devices, welding equipment, metal processing equipment, etc., can solve the problems of low production efficiency, easy to stick foreign objects, time-consuming and labor-intensive problems, and achieve the goal of improving production efficiency and saving labor and time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

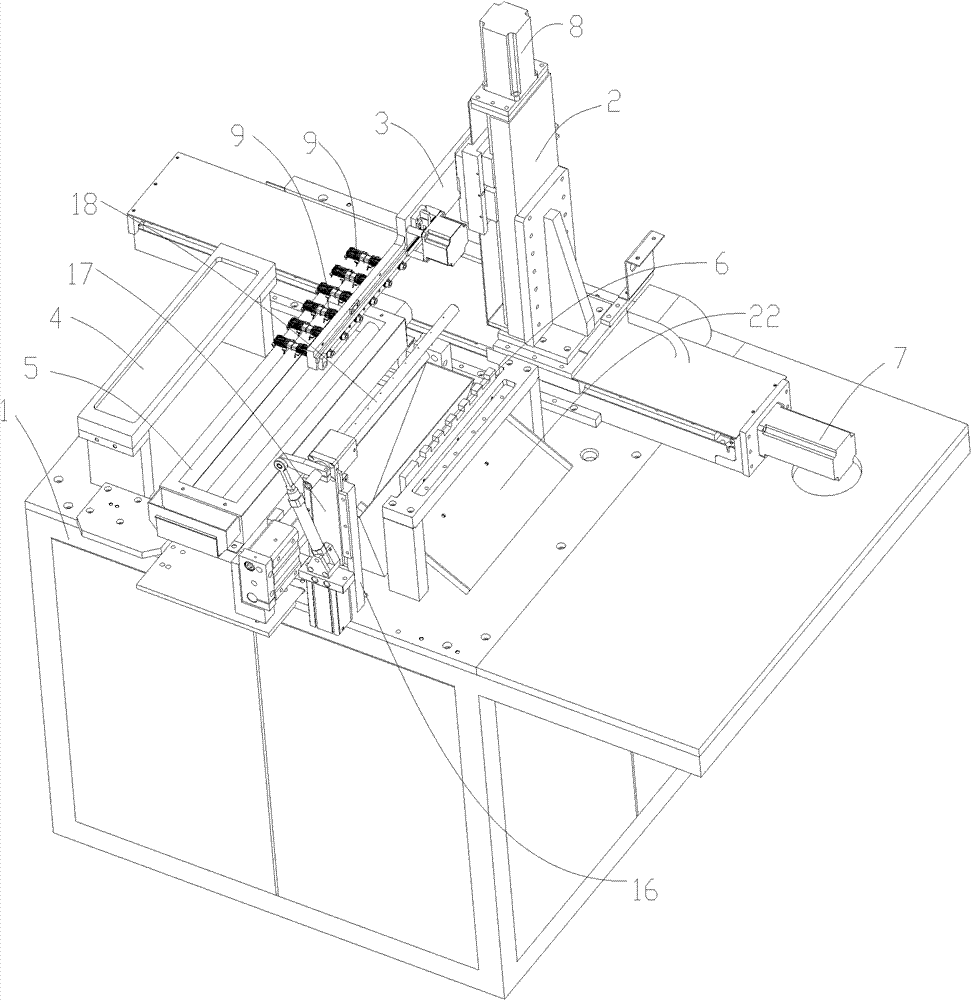

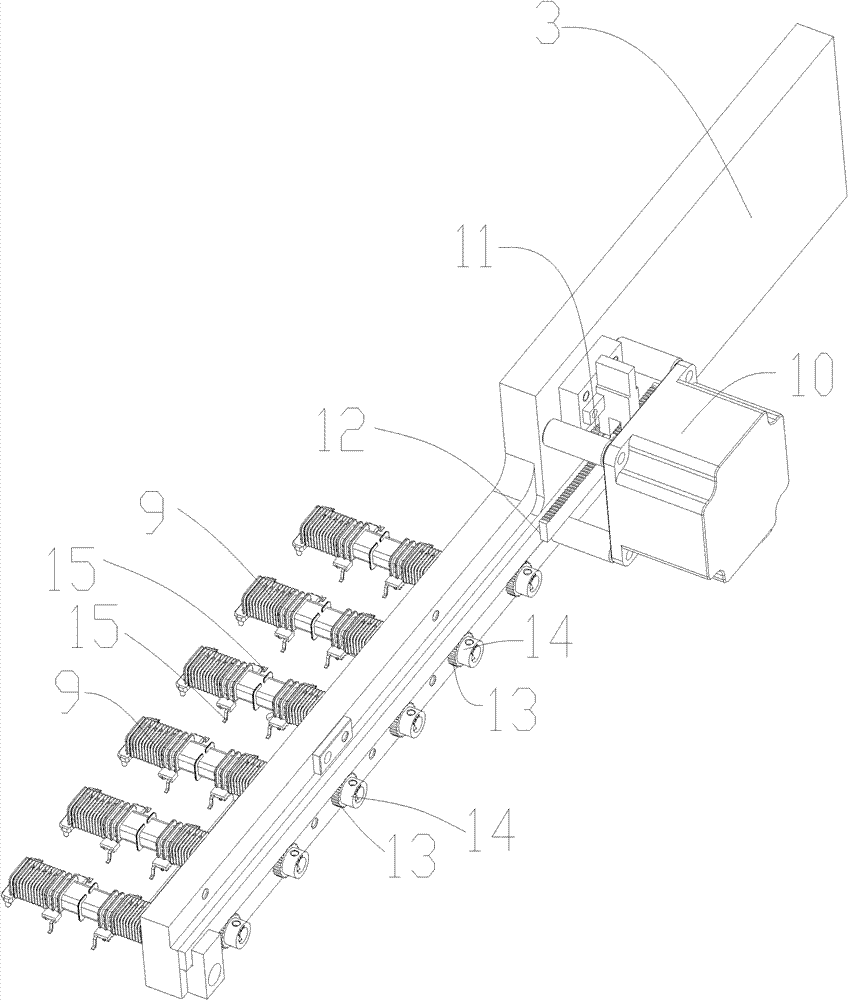

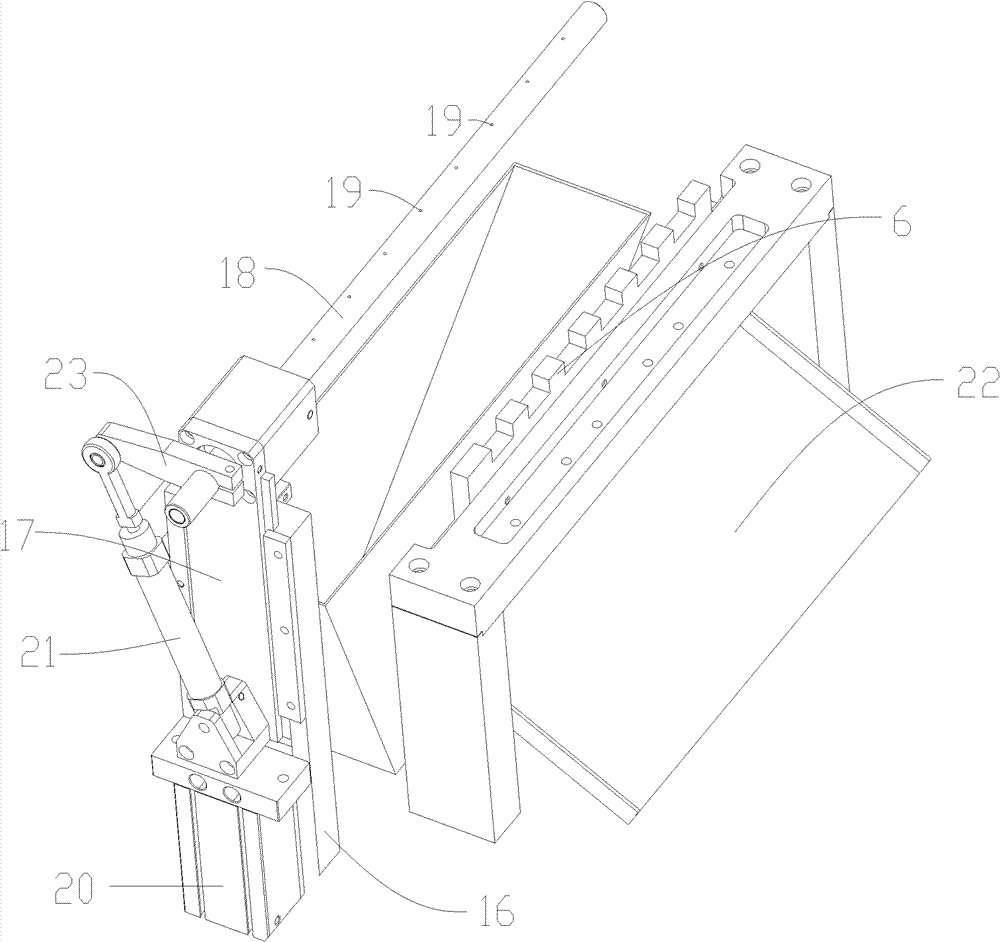

[0012] exist Figure 1-3 Among them, the product 9 to be soldered has a socket, and the product 9 has outwardly protruding soldering contacts 15 on the opposite outer sides of both sides of the socket. The connection base 2 on the support base 1, the mounting plate 3 that can be moved vertically on the connection base 2, can be rotated up and down on the mounting plate 3 and can be inserted into the socket of the product 9 to support The supporting board of the product, the first driving mechanism capable of driving the connecting seat 2 to move, the second driving mechanism capable of driving the mounting plate 3 to move, and the third driving mechanism capable of driving the supporting board to rotate are arranged on the supporting base 1 The flux tank 4 and the molten tin furnace 5 that can be inserted into the solder contact pin 15 of the product 9 and located...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap