System for purging exporting emulsions of cold continuous rolling mill

A technology of cold tandem rolling mill and emulsion, which is applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of insufficient purging, difference in purging effect, and affecting effect, so as to ensure the purging effect and benefit Reasonable effect of maintenance, overhaul and layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below, the present invention will be further described in conjunction with the accompanying drawings.

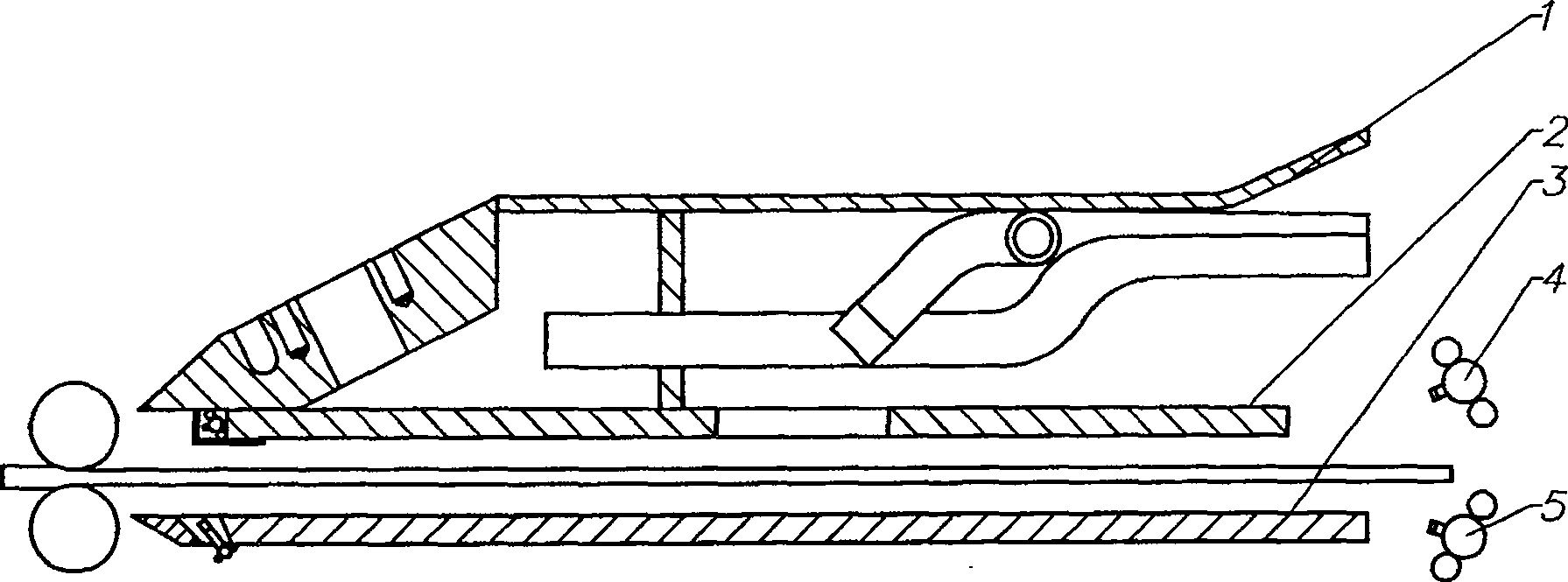

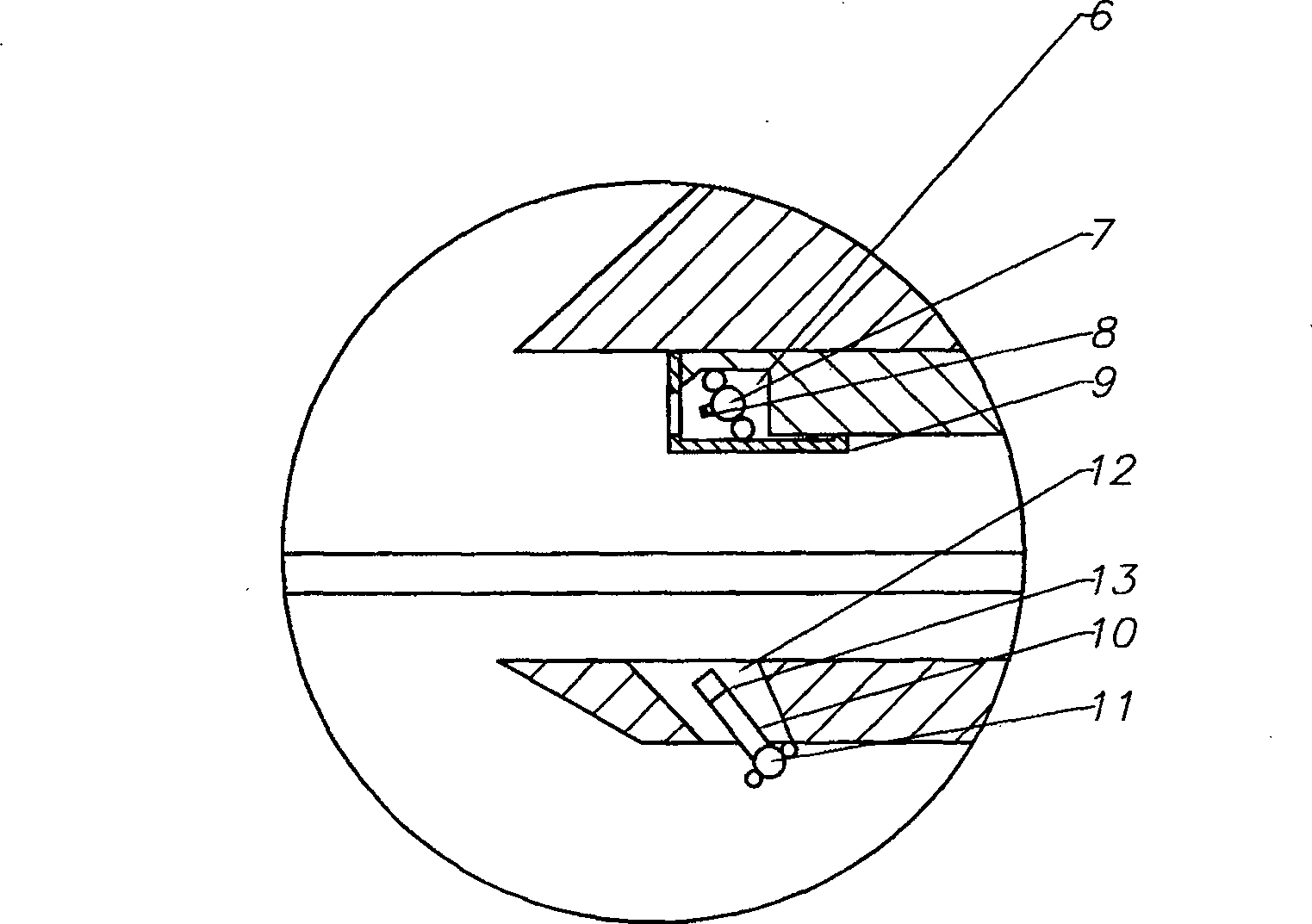

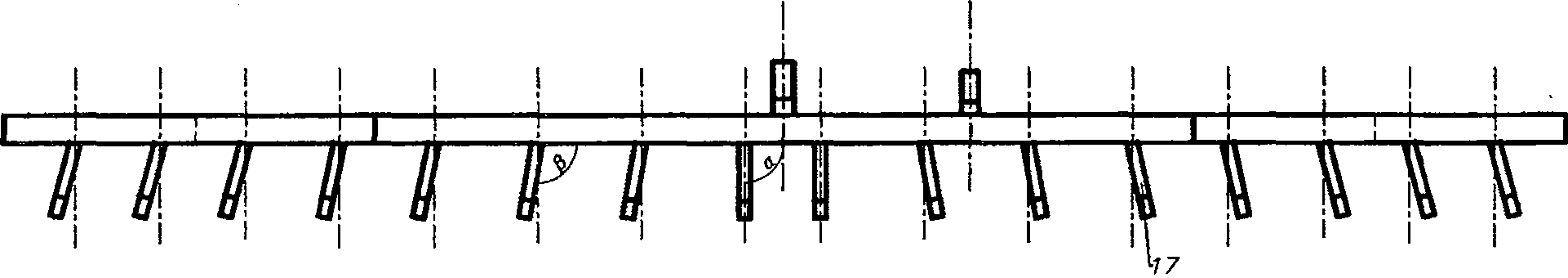

[0018] The present invention has 4 sets of outlet emulsion purging systems for cold tandem rolling mills, each of which includes a main air duct, a branch pipe 17 and an air nozzle 13. The main air duct is composed of a middle air duct 14, a long air duct 18 and a short air duct 19. consist of. Depend on figure 1 , figure 2 It can be seen that the four sets of purging devices are respectively installed on the head and the guide plate outlet of the upper anti-wrapping guide plate 1 and the lower anti-wrapping guide plate 3 of the rolling mill, that is, one set at the top and bottom of the head, and the guide plate outlet is the upper purge device 4 and the guide plate outlet at the guide plate outlet. Lower purge device 5. The head of the upper anti-wrap guide plate lower guide plate 2 has an upper anti-wrap guide plate lower guide plate air groove 6; The purging ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap