Self-excited pulse energy-saving valve

An energy-saving valve and pulse-type technology, applied in cleaning methods and appliances, chemical instruments and methods, and cleaning methods using gas flow, etc., can solve the problems of low pulse frequency, energy waste, unfavorable automatic production, etc., and achieve pulse frequency. The effect of adjusting and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

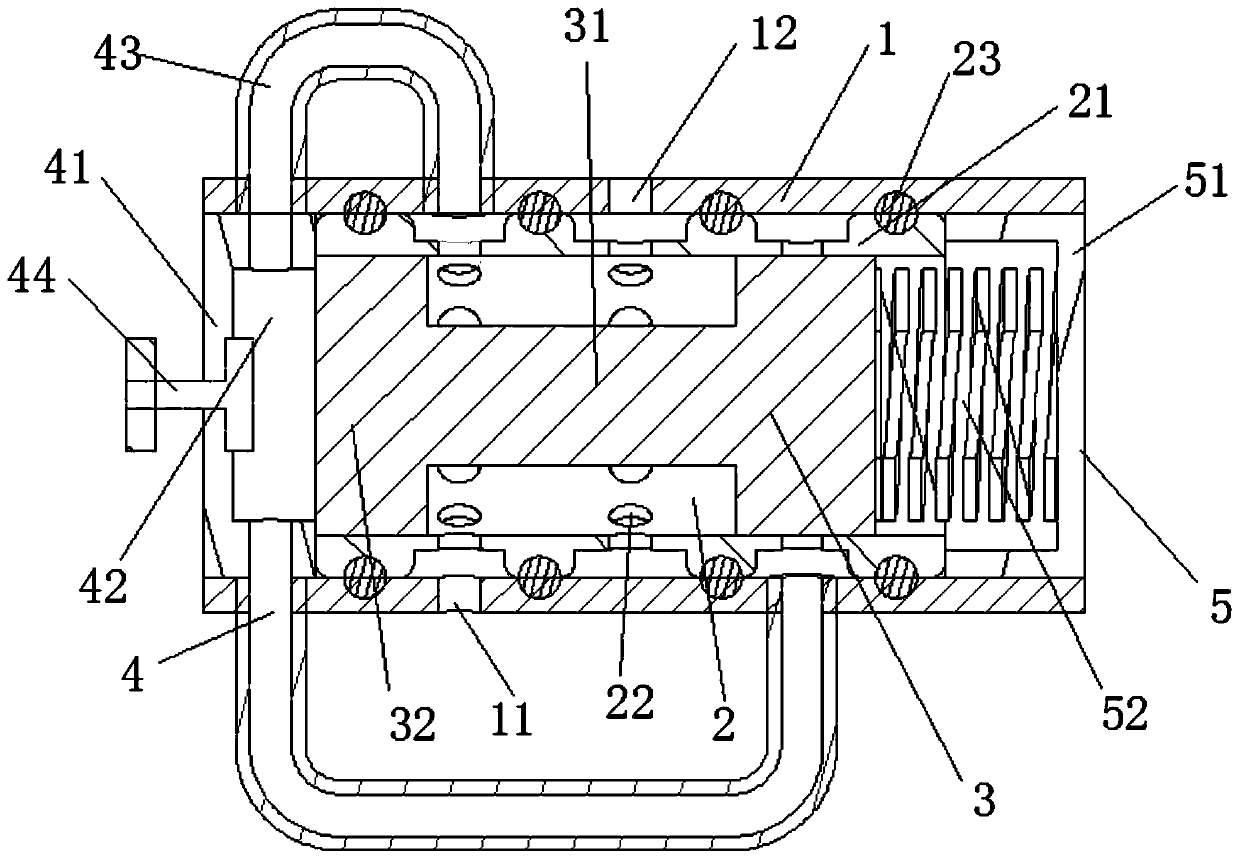

[0031] see figure 1 , this embodiment shows a self-excited pulse energy-saving valve:

[0032] It includes a housing 1 with an air inlet 11 and an air outlet 12 correspondingly opened on the upper end, a valve core sleeve 2 arranged in the housing 1 and used in conjunction with the air inlet 11 and the air outlet 12, and a spool set movably on the valve core The regulating valve core 3 in the sleeve 2, and the pulse regulating assembly 4 and the sealing pressure assembly 5 respectively arranged in the housing 1 at both ends of the regulating valve core 3;

[0033] The outer end of the spool cover 2 is provided with a number of connecting frustums 21, and the main body of the spool cover 2 between the two connecting truncated frustums 21 is provided with communicating air holes 22, and the joint between the connecting frustums 21 and the inner wall of the housing 1 is provided with Seals consisting of sealing rings;

[0034] In this embodiment, the number of connecting cones ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap