Particulate matter measuring instrument and working method thereof

A working method and measuring instrument technology, which is applied in the field of particle measurement, can solve problems such as pollution impurities, optical lens pollution in the measurement area of the measuring instrument, and influence on the accuracy of particle concentration measurement, so as to avoid pollution and avoid mutual pollution and interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

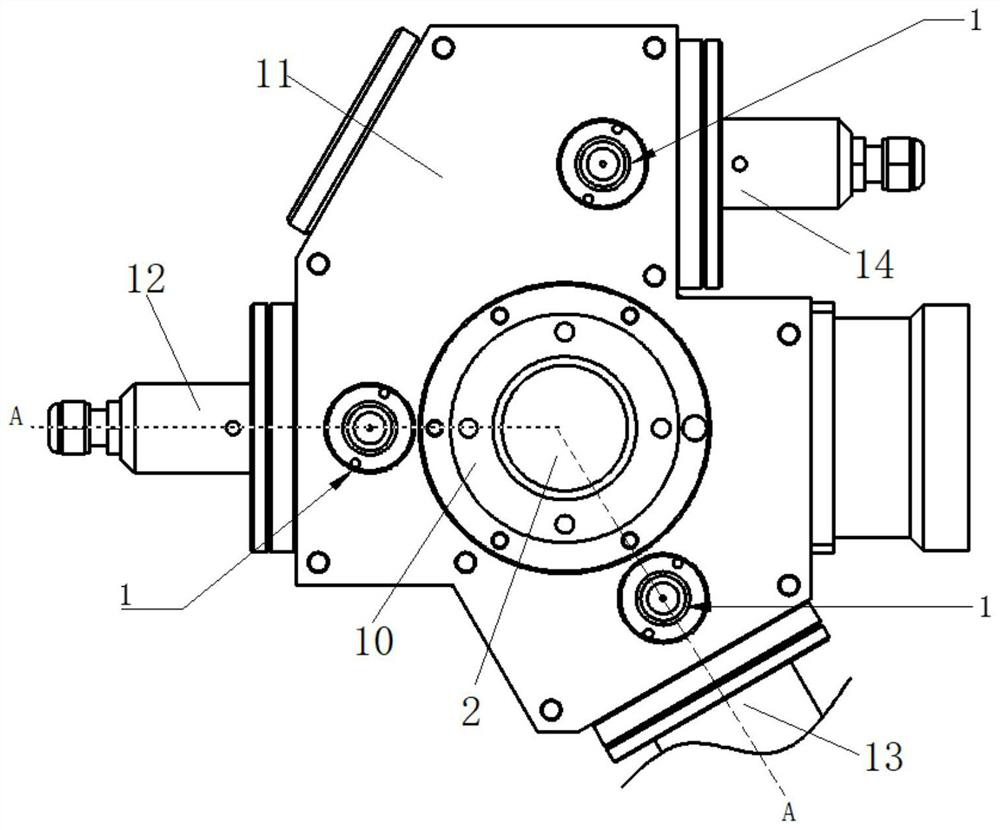

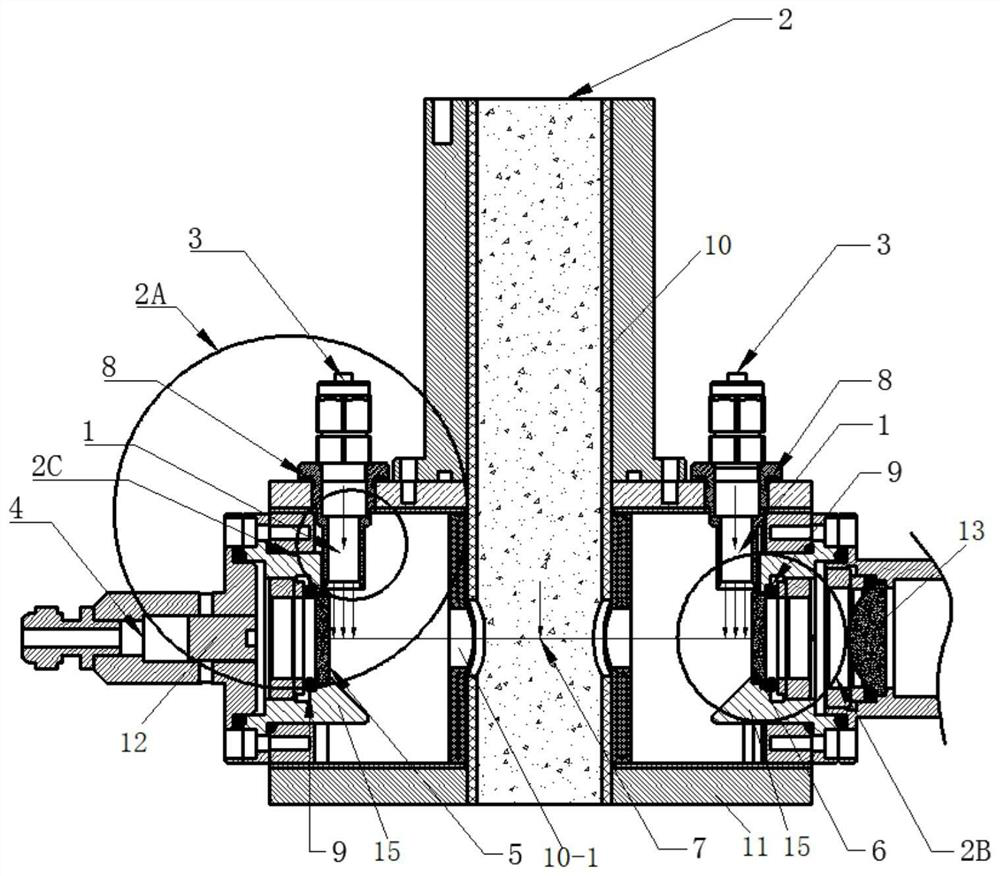

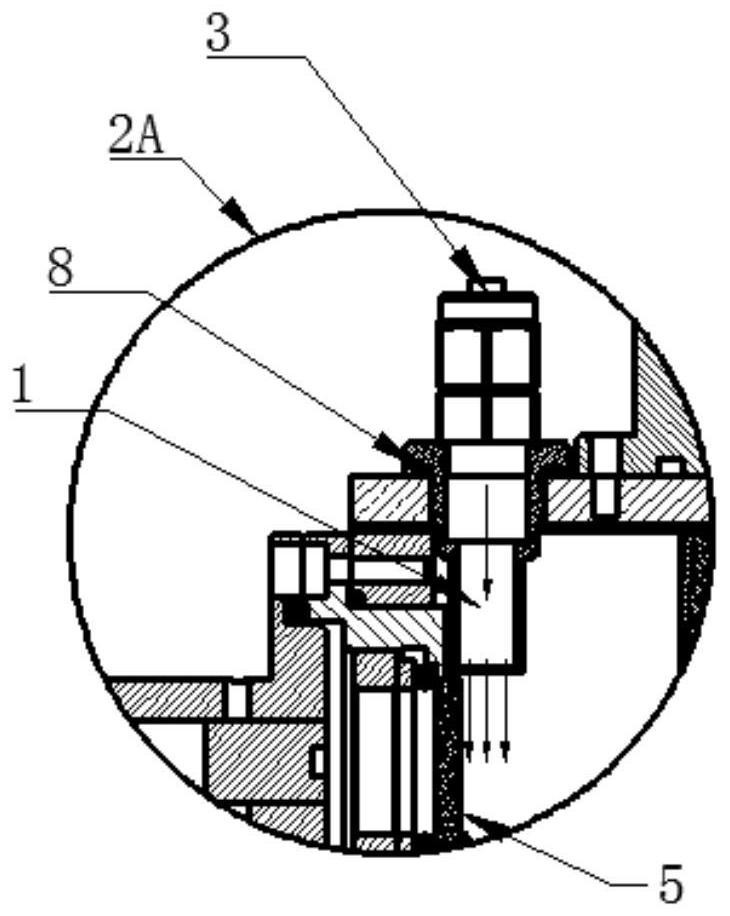

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0031] refer to Figure 1-Figure 5 , the particle measuring instrument of the present invention includes a measuring gas chamber, a target sample gas channel 10, an emitting light source assembly 12, a sampling assembly 13, a calibration assembly 14 and a spray column 1, the target sample gas channel 10 runs through the measuring gas chamber, and the emitting light source assembly 12, The sampling assembly 13 and the calibration assembly 14 are installed on the measurement gas chamber and distributed in the circumferential direction of the target sample gas channel 10; The positions of the optical lenses are all provided with a through hole 10-1, and the through hole 10-1 communicates with the measuring air chamber. On the measuring air chamber, a spray column 1 is installed on one side of the optical lens, and the injection direction of the spray colum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap