Engine cover used for vehicle

A technology for hoods and vehicles, applied to vehicle parts, vehicle safety arrangements, superstructures, etc., can solve problems such as easy fractures, decreased pedestrian protection performance, and large line length changes, so as to prevent fractures and ensure pedestrian protection performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

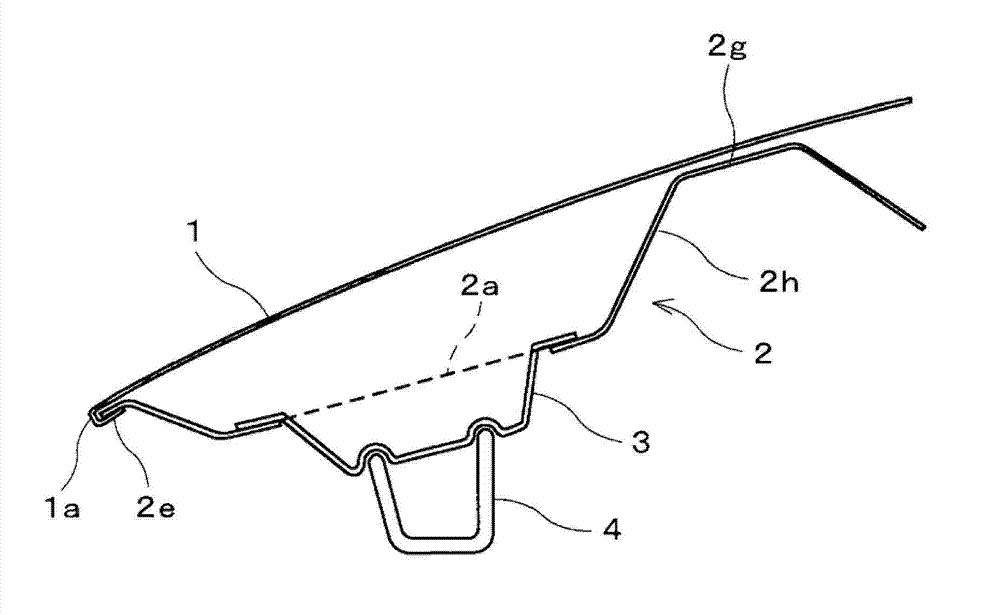

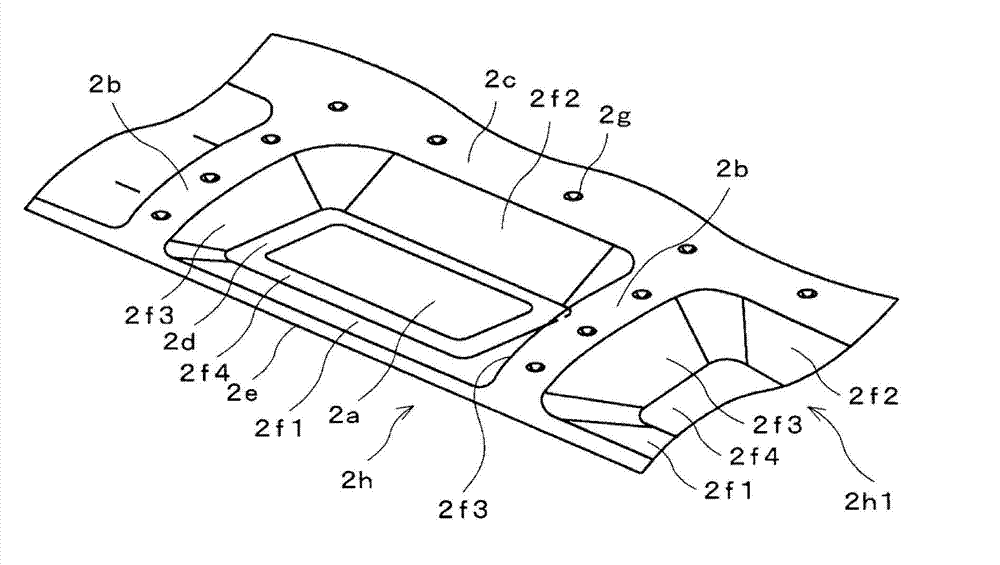

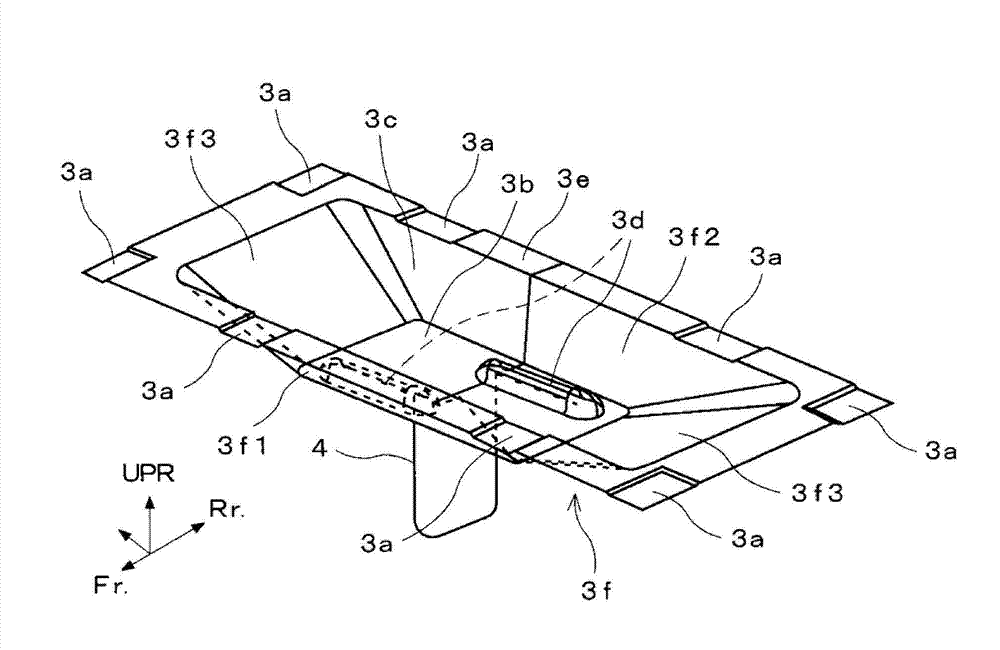

[0092] Hereinafter, embodiments of the present invention will be specifically described with reference to the drawings. figure 1 is a cross-sectional view showing a vehicle engine cover according to the first embodiment of the present invention in the direction of vehicle travel, figure 2 is a perspective view showing a part of the inner panel 2, image 3 is a perspective view showing the lock reinforcement member 3, Figure 4 It is a perspective view showing a state in which the lock reinforcement member 3 is fixed to the inner panel 2 . The hood of a vehicle such as a motor vehicle is openably and closably arranged on the engine room, and consists of an upper or outer outer panel 1, an inner panel 2 arranged on the lower surface side of the outer panel 1, and a concave portion of the inner panel 2. 2

[0093] h The locking reinforcing member 3 fixed and the striker 4 fixed to the locking reinforcing member 3 are constituted. The striker 4 is inserted into a hole of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com