Rope supporting machine

A rope holder and rope groove technology, which is applied in the field of auxiliary equipment, can solve the problems of efficiency, safety, and performance that cannot meet the needs of production, and achieve the effects of compact structure, rapid replacement and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below according to the accompanying drawings and embodiments.

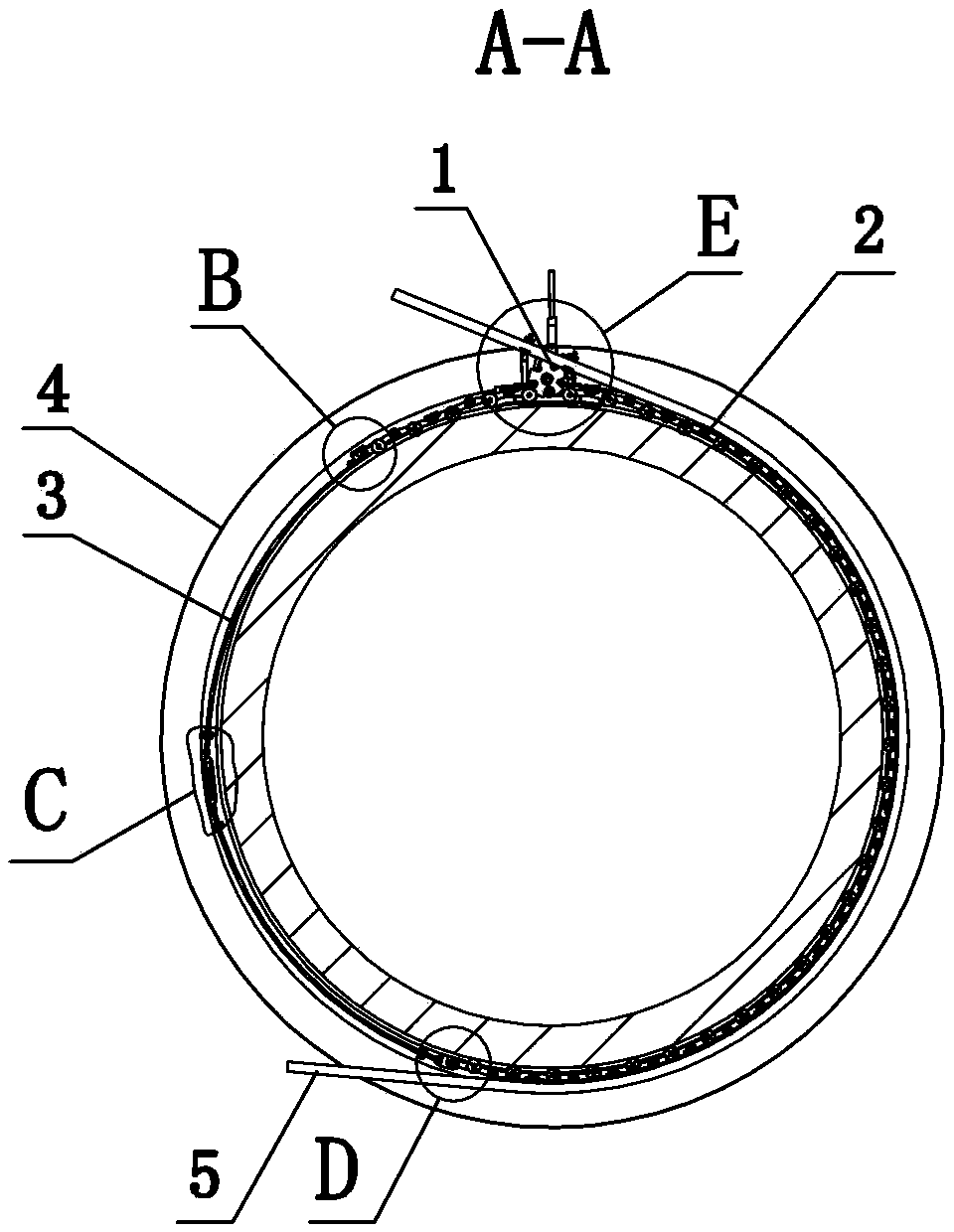

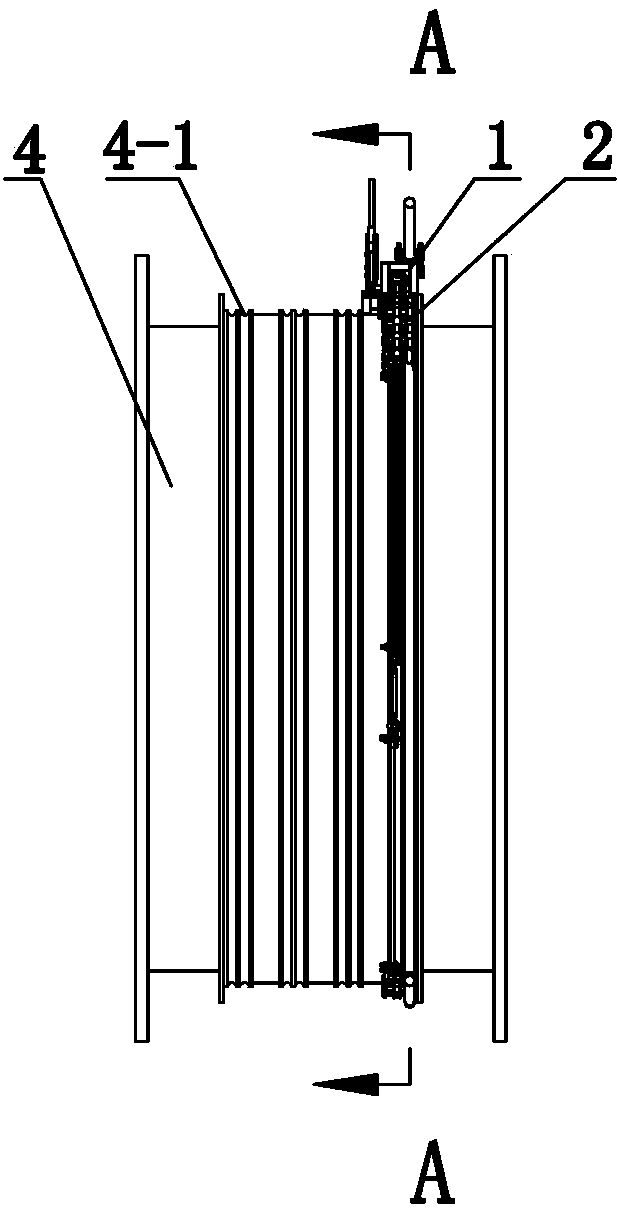

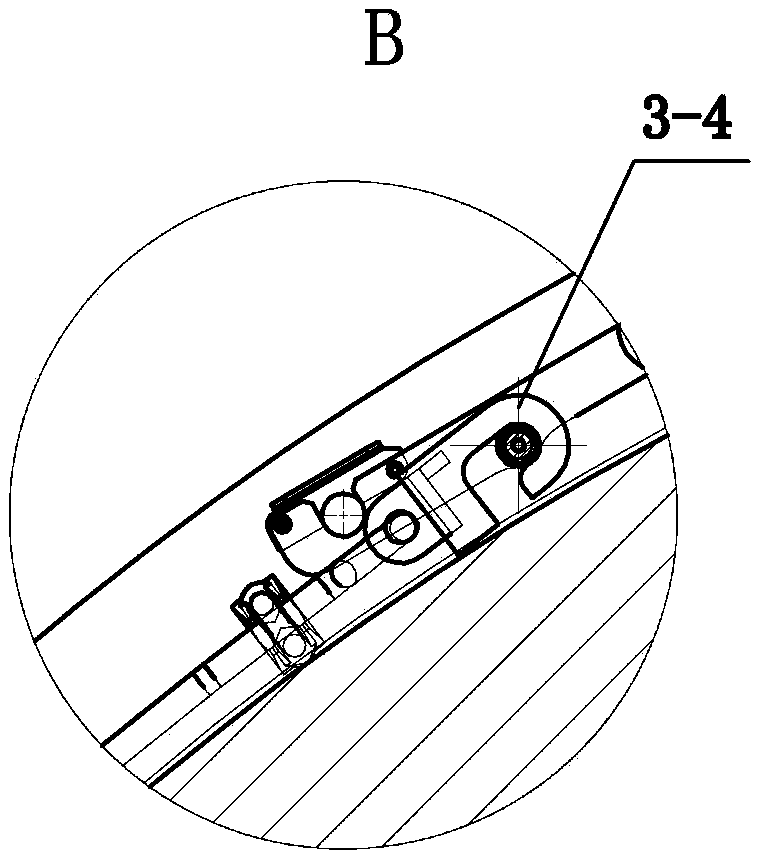

[0030] A rope holder as shown in the accompanying drawings, it is installed between the outer circle of the active friction roller 4 and the steel wire rope 5 along the rope groove 4-1 of the active friction roller 4, and the rope holder includes a drive frame 1, The wheel chain 2 and the connecting body 3, the wheel chain 2 is hinged by a plurality of wheel units 6, the wheel unit 6 includes two strip plates 6-1 of equal length, two A plurality of wheel shafts 6-4 are arranged between each strip plate 6-1 to form a wheel frame structure, each of the strip plates 6-1 is divided into front and rear sections, and the two strip plates 6-1 The front wheel frame formed in the front section is narrower than the rear wheel frame formed in the rear section, and the front wheel frame and the rear wheel frame are hinged together through the axle 6-4, and the rope pulley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com