A liquid stepless amplitude modulation exciter for a vibratory road roller

A vibratory roller, stepless amplitude modulation technology, applied in the field of road construction machinery, can solve problems such as unfavorable remote control, prolonged installation and maintenance time, complex structure, etc. Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

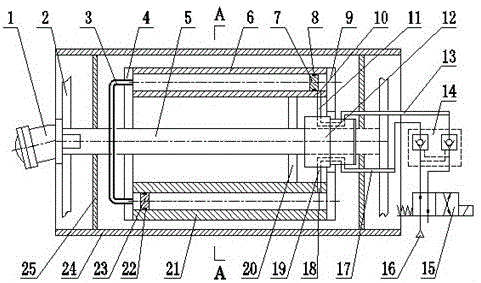

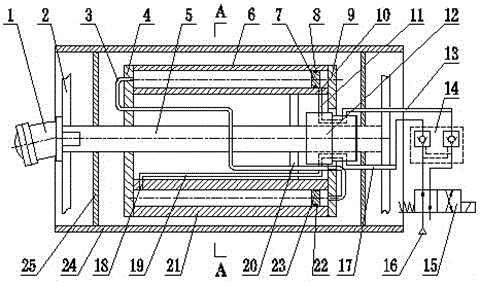

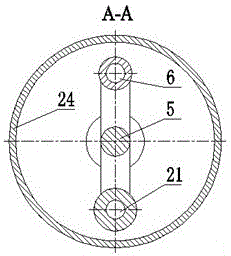

[0013] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0014] figure 1 It is a liquid stepless amplitude modulation exciter for a vibratory roller of the present invention, which consists of: the output end of the hydraulic motor 1 installed on the frame 2 is connected to one end of the vibration shaft 5; the left end of the vibration shaft 5 is connected to the left end plate 4 through the spline, The right end is connected to the right end plate 9, and the light tube 6 and the heavy tube 21 are installed between the left end plate 4 and the right end plate 9; the light tube 6 and the heavy tube 21 are arranged symmetrically at 180° on both sides of the axis of the vibration shaft 5, and the inside is respectively equipped with The light tube piston 7 and the heavy tube piston 23, the light tube piston 7 is sealed with the light tube 6 by the light tube seal 8, and the heavy tube piston 23 is sealed with the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com