Automatic control system and automatic control method used for protecting face guard of coal mine underground fully mechanized coal face support

An automatic control system and fully mechanized mining face technology, applied in mine roof support, mining equipment, earthwork drilling and mining, etc., can solve problems such as liquid leakage at the working face, easily injured workers, equipment failure, etc., and achieve guaranteed recovery speed , to meet the effect of personnel protection and collision prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

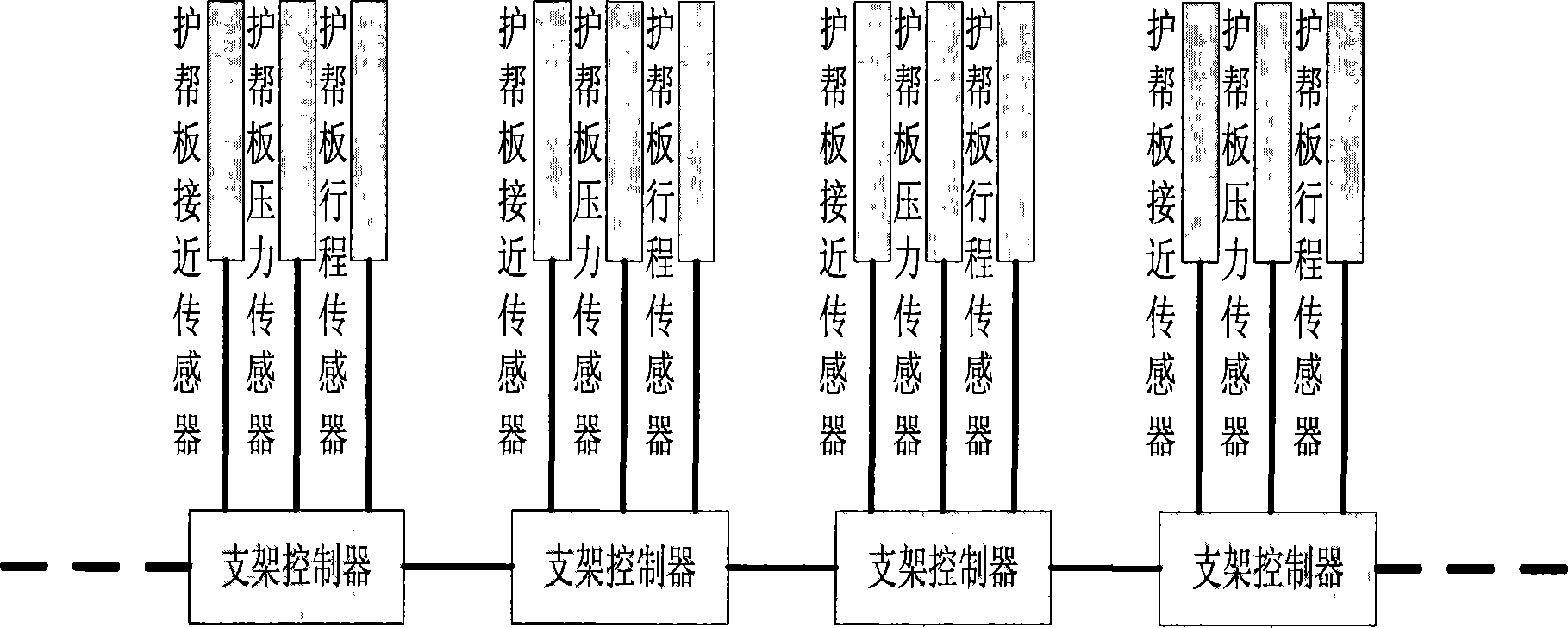

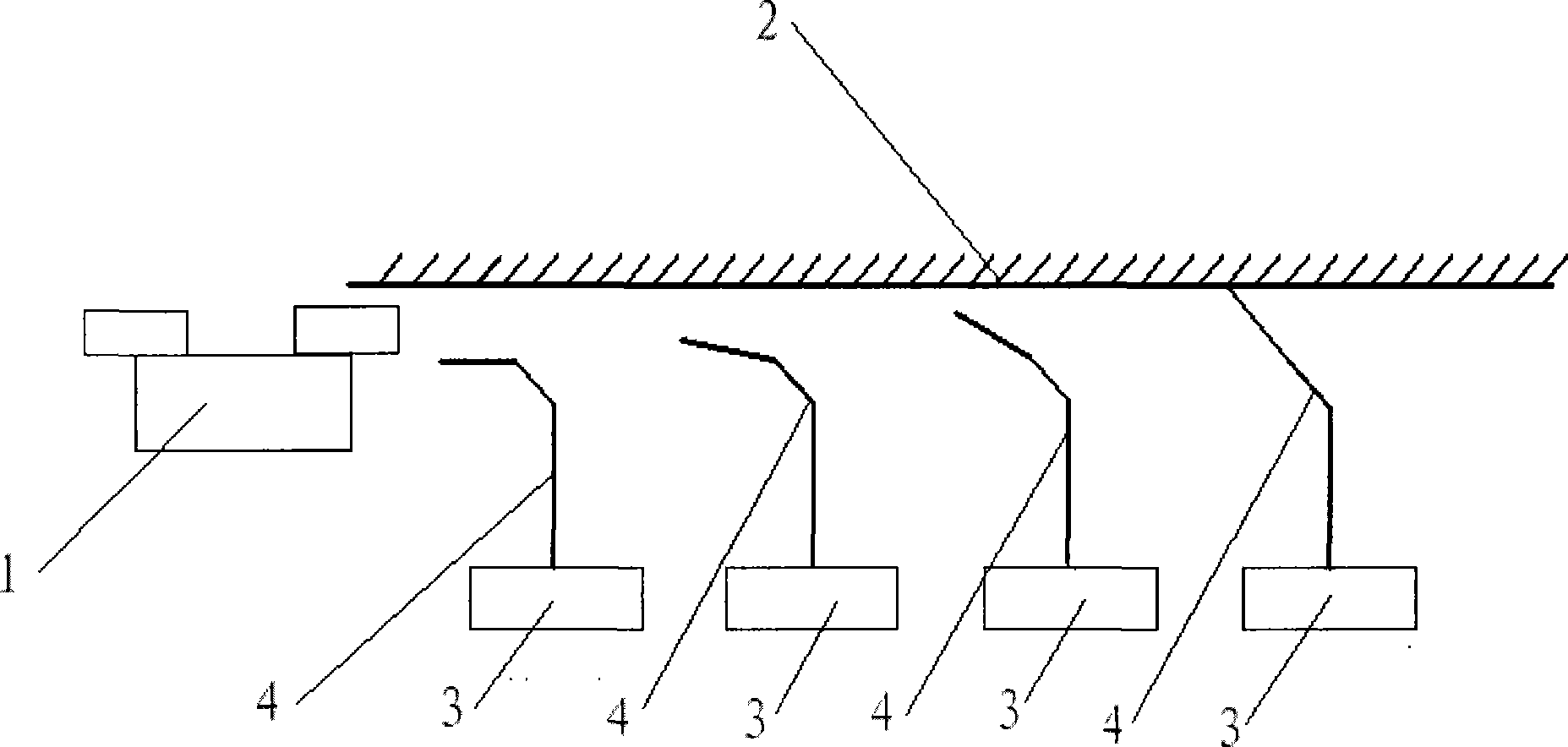

[0021] See attached Figure 1-2 , an automatic control system for protecting the hydraulic support side guard of the fully mechanized mining face in coal mines, including a hydraulic support, a proximity switch, a pressure sensor, a travel sensor and a support controller, wherein the proximity switch is installed on the top beam of the hydraulic support Above, the pressure sensor is installed in the oil cylinder that controls the movement of the side guard of the hydraulic support, the stroke sensor is installed on the side guard of the hydraulic support, and the support controller is installed on the hydraulic support.

[0022] The proximity switch, the pressure sensor, and the travel sensor are respectively connected with the bracket controller to establish signal communication. The proximity switch is used to detect the retracted state (whether it is retracted) and the retracted state (whether it is in the process of extending / retracting) of the side guard of the hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com