Centrifugal fan

A centrifugal fan and blower technology, applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of easy fires, flammables, production safety hazards, etc., to eliminate production safety hazards and prevent fires , the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

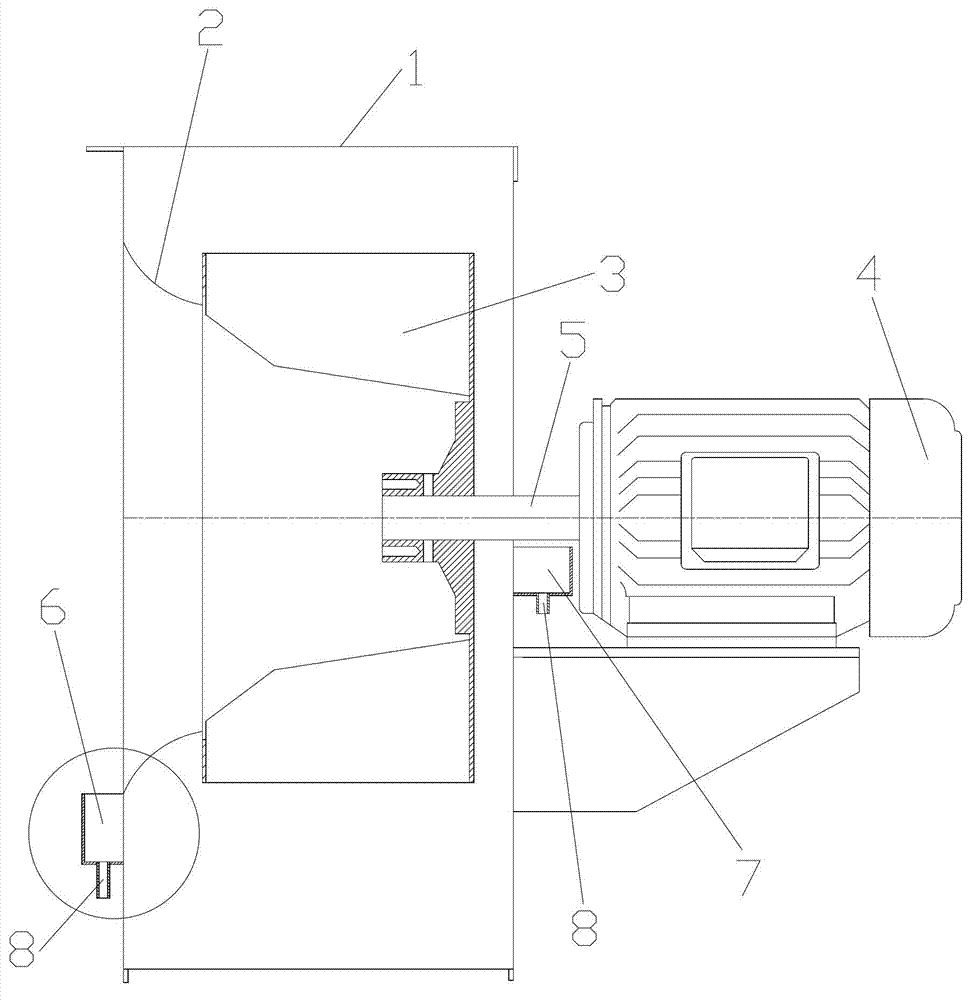

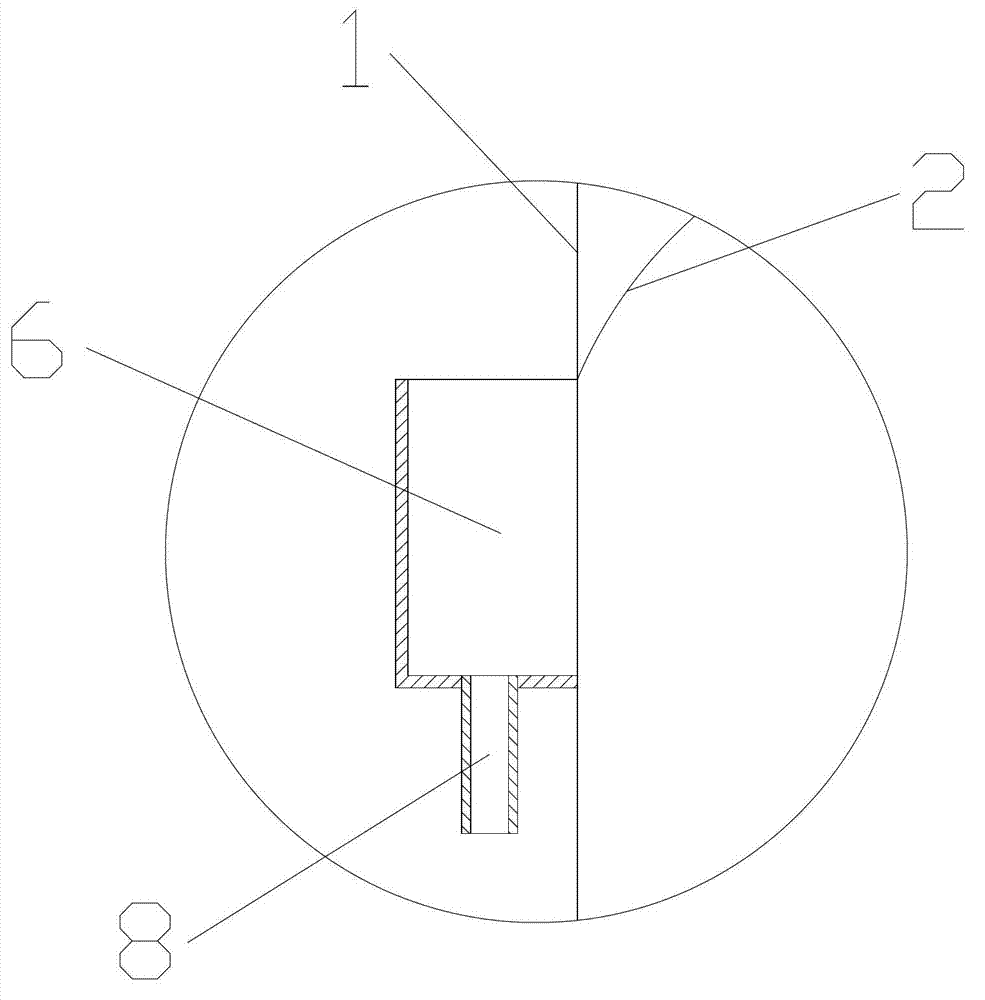

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] as attached figure 1 The shown centrifugal fan of the present invention includes a fan housing 1, an air collecting ring 2, an impeller 3 and a motor 4, and the fan housing 1 is provided with an air collecting ring 2 and an impeller 3, so that The motor 4 is arranged outside the fan housing, the output shaft 5 of the motor 4 is connected to the impeller 3, and the front side and the rear side of the fan housing 1 are respectively provided with a first oil receiving pan 6 and a second oil receiving pan 6. Pan 7; the first oil pan 6 is located below the wind collecting ring 2; the second oil pan 7 is located below the motor output shaft 5; the first oil pan 6 and the second oil pan 7 Below is provided with the drain pipe 8 that communicates with the inside of the oil pan.

[0014] In the centrifugal fan described in the present invention, after the medium containing greasy compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com