Piston rod supply oil supply pressure cylinder

A piston rod and oil supply technology, which is applied in the direction of fluid pressure actuating devices, can solve the problems of multiple oil cylinders and single action of the oil cylinder, and achieve the effects of improving integration, overcoming single action, and simplifying the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

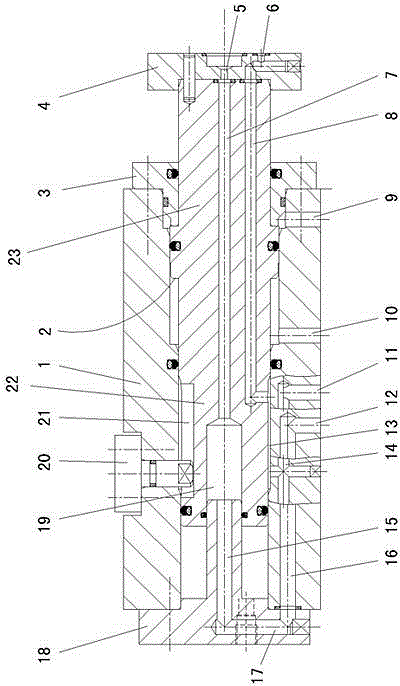

[0008] Such as figure 1 Shown: 1 is the cylinder body, the cylinder body 1 is equipped with a piston 2, there is a first oil port 9 and a second oil port 10 on the cylinder body 1, and the first oil port 9 communicates with the oil chamber on the right side of the piston 2 , the second oil port 10 communicates with the left oil chamber of the piston 2. The right piston rod 23 that links to each other with piston 2 stretches out from the center hole of the front cover 3 of cylinder body 1 right end, is provided with rear cover 18 at the left end of cylinder body 1, between front cover 3 and rear cover 18 and cylinder body 1 is Bolted connection.

[0009] Piston 2 is connected with left piston rod 22, and piston 2, right piston rod 23, left piston rod 22 are integral structures. A left piston rod cavity 19 is processed inside the left piston rod 22, and a rightward protruding part is arranged on the rear cover 18. The rightward protruding part on the cover 18 can move axially...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap