Leakage repairing system of oil transportation pipeline

An oil pipeline and leak repair technology, which is applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of corrosion and oil leakage, consuming a lot of manpower, material resources, and low work efficiency, and achieves high work efficiency and automation. High degree, good leak trapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be described in further detail below in conjunction with the accompanying drawings.

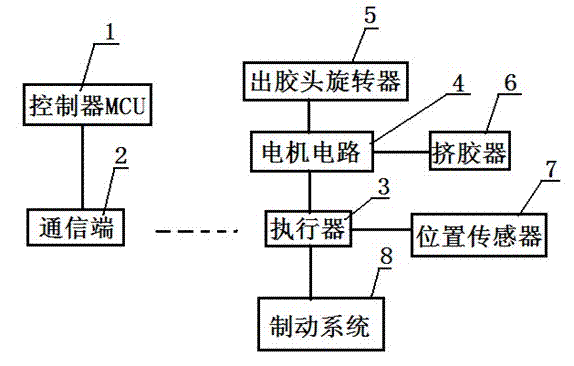

[0008] See attached figure 1 , an oil pipeline leakage repair system, including a controller MCU1, the communication terminal 2 of the controller MCU1 is wirelessly connected to the actuator 3, the actuator 3 is connected to the motor 4, the position sensor 7 and the braking system 8 respectively, and the connection of the motor 4 There are glue head rotator 5 and glue extruder 6.

[0009] The working principle of the present invention is:

[0010] The controller MCU1 conducts wireless communication between the communication terminal 2 and the actuator 3, and issues commands to the actuator. The actuator assigns tasks according to the commands of the controller MCU1. Stop action, the position sensor 7 detects the accurate position data of the leak in the oil pipeline according to the task, and sends it back to the controller MCU1 through the actuator. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com