Apparatus and method for detecting flatness

The technology of a detection device and detection method, which is applied in the field of optical measurement, can solve the problems of time-consuming and large amount of calculation, and achieve the effect of small amount of calculation and short detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

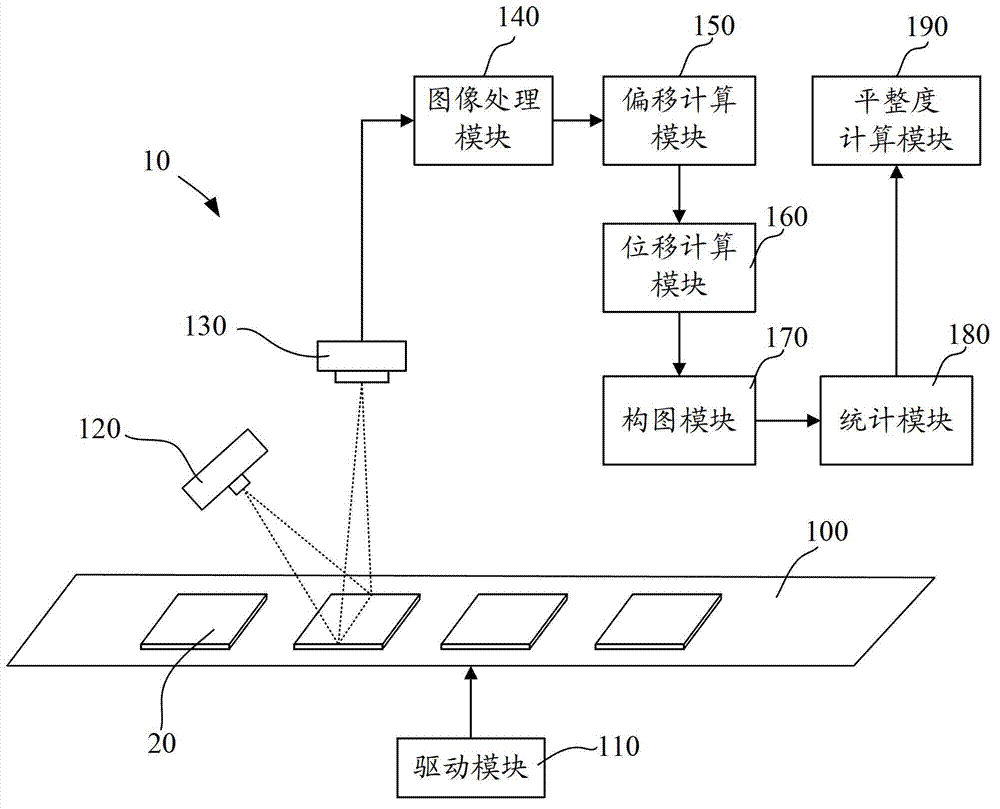

[0043] Such as figure 1 As shown, it is a schematic structural diagram of the flatness detection device 10 of an embodiment. It includes: carrying platform 100 , drive module 110 , laser module 120 , sensor module 130 , image processing module 140 , offset calculation module 150 , displacement calculation module 160 , composition module 170 , statistics module 180 and flatness calculation module 190 .

[0044] The carrying platform 100 is used for carrying the object 20 to be inspected.

[0045] The driving module 110 is used to drive the carrying platform 100 to move, so as to drive the object 20 to be inspected to move.

[0046] The laser module 120 is used for emitting a linear laser to the carrying platform 100 . That is, when the object 20 to be inspected is placed on the carrying platform 100 , the linear laser is irradiated on the surface of the object 20 to be inspected.

[0047] The sensing module 130 is used to acquire a plurality of inspection images of the linea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com