Commodity storage device for vending machine

A technology of automatic vending machines and storage devices, applied in the direction of coin-free or similar appliances, coin-operated equipment for distributing discrete items, and coin-operated equipment for distributing discrete items, which can solve the problem of increased material costs and work Increased working hours etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

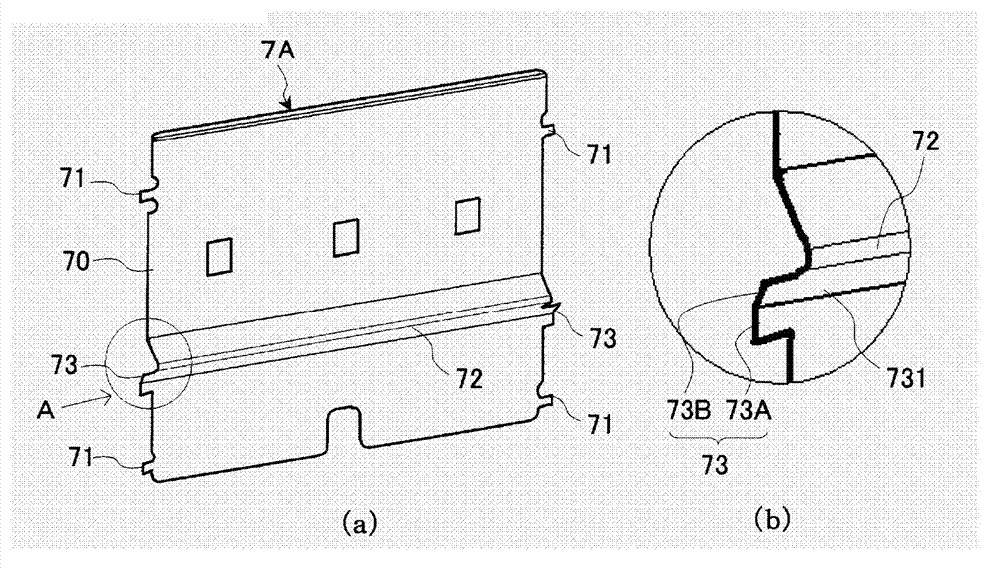

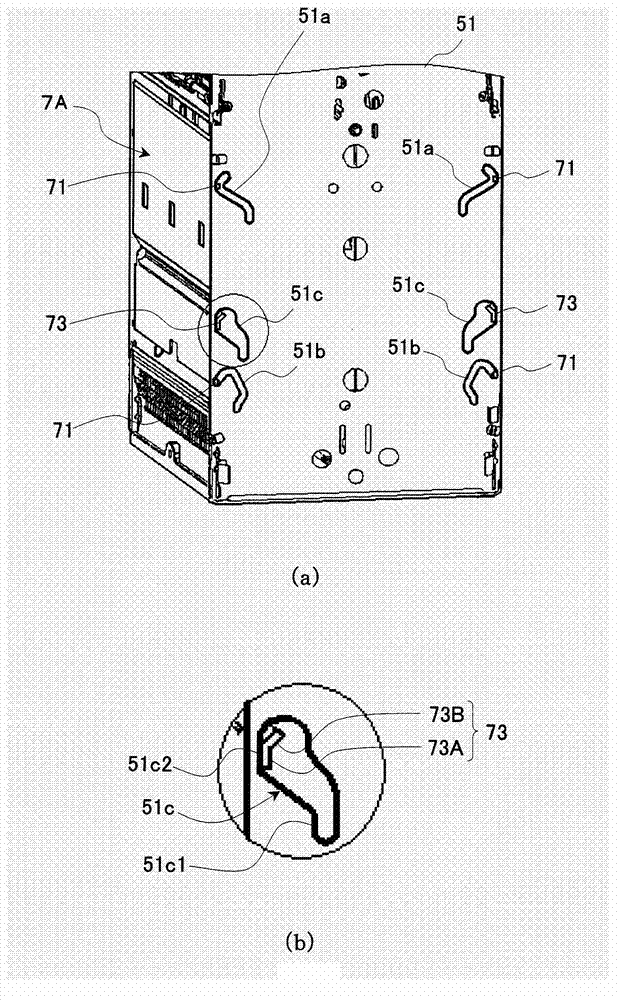

[0042] Hereinafter, a product storage device for an automatic vending machine according to an embodiment of the present invention will be described with reference to the drawings. In addition, the similarities and differences between the commodity storage device of the automatic vending machine in the embodiment of the present invention and the existing device are mainly the passage width limiting plate 70, because the overall structure of the automatic vending machine is different from that of the existing device. Figure 4 The same as shown, in addition, the composition of the product output device 6 is the same as Image 6 are the same as shown, so it is appropriate to refer to Figure 4 and Image 6 Be explained.

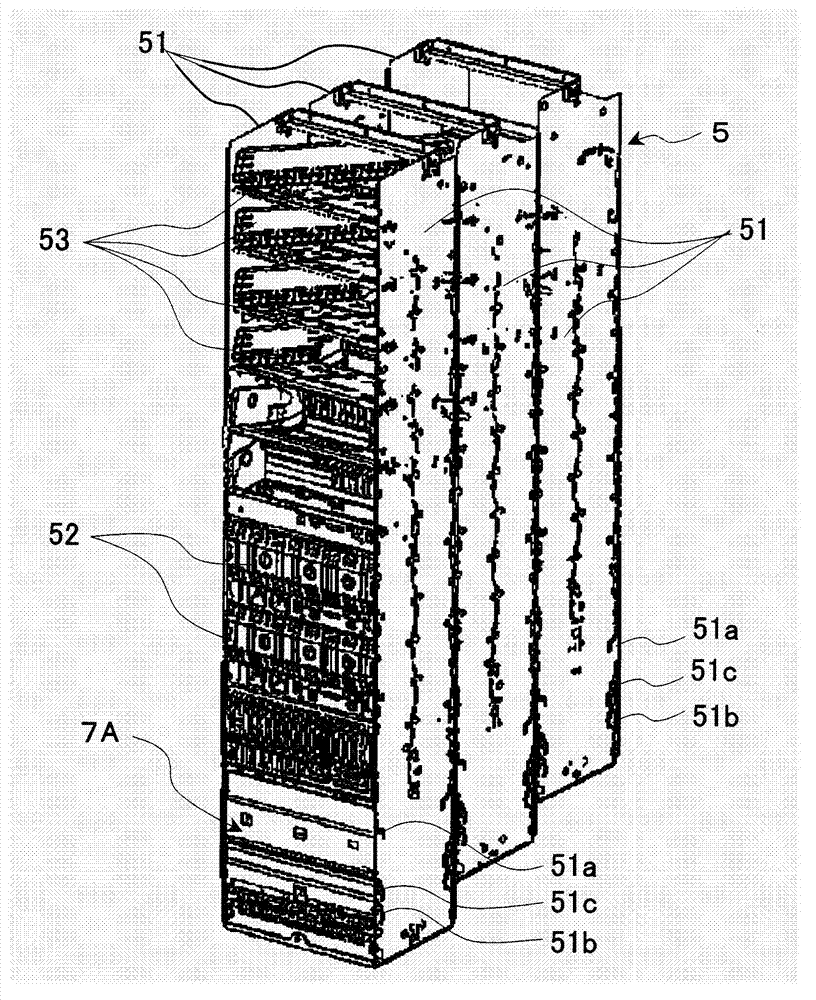

[0043] figure 1 Among them, 5 is a product storage rack, which has a pair of left and right frame side plates 51, 51, and on the left and right pair of frame side plates 51, 51, an arc-shaped bow frame 52 is connected and erected in the vertical direction. By...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com