Light emitting device

A technology for light-emitting devices and light-emitting elements, which is applied to electrical components, electrical solid-state devices, circuits, etc., can solve problems such as hindering heat dissipation, uneven stress distribution, and thermal deviation in light-emitting devices, and achieves high reliability and improved heat dissipation. , to prevent the effect of uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

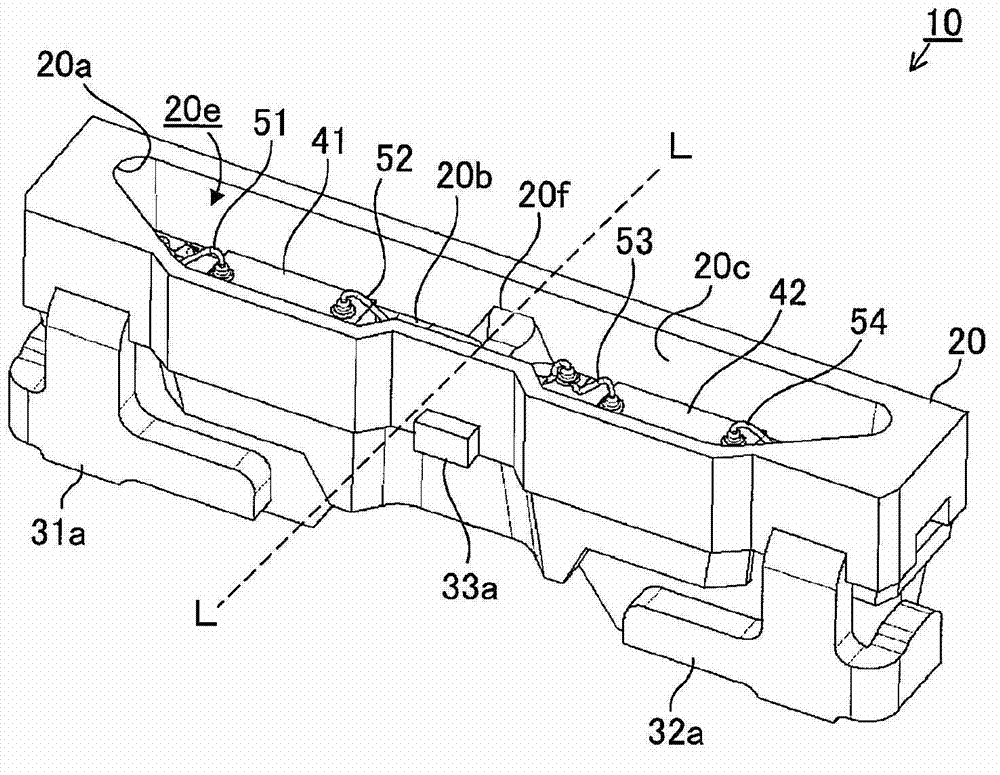

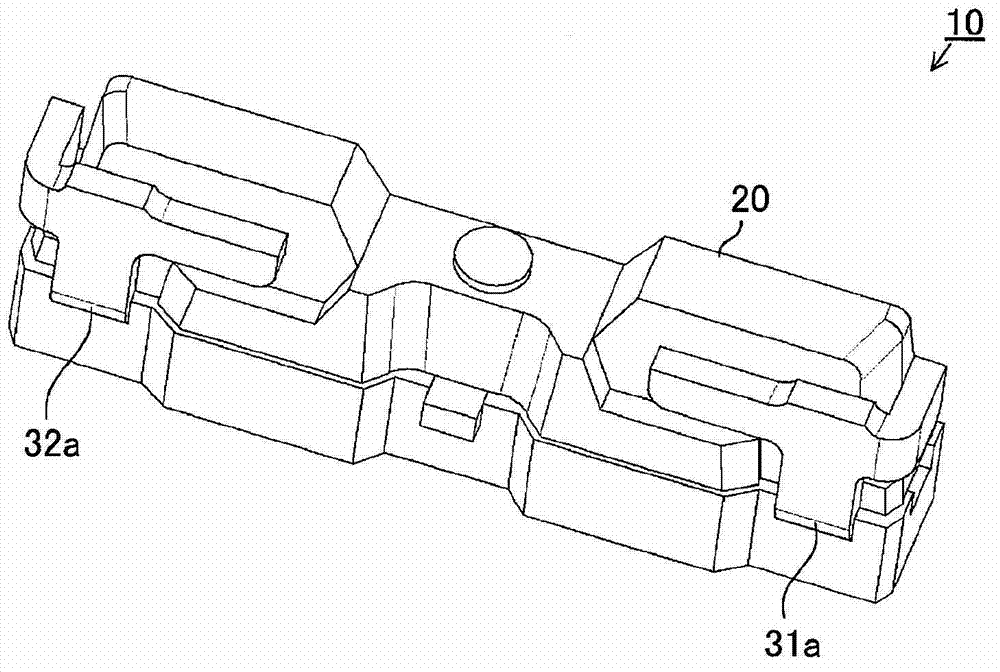

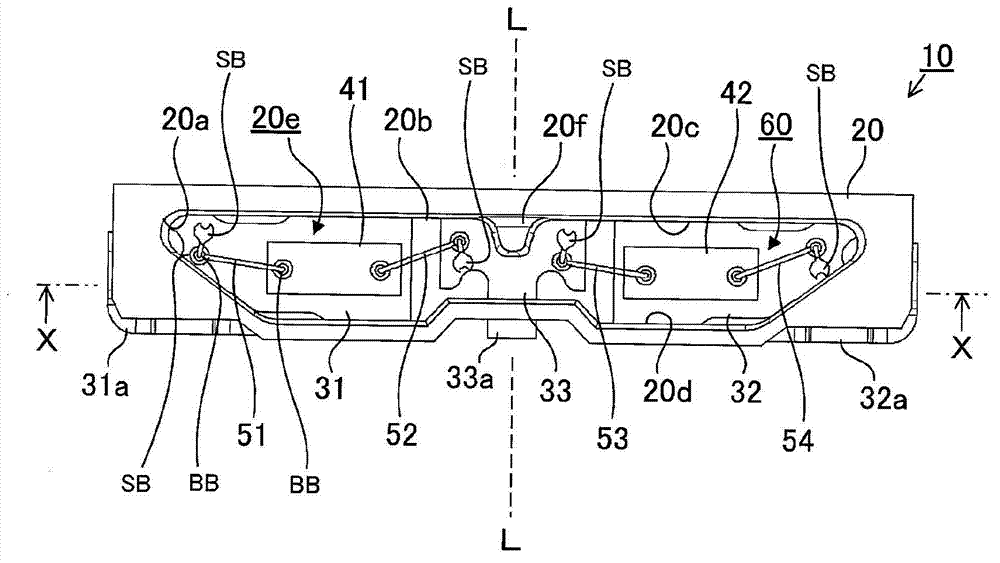

[0049] As shown in FIGS. 1 and 2 , the light-emitting device 10 in Embodiment 1 includes a housing 20 (including an opening 20 a , a bottom surface 20 b , inner surfaces 20 c , 20 d , an accommodation recess 20 e , and a columnar portion 20 f ), and a lead frame 31 . to 33, light emitting elements 41, 42, bonding wires 51 to 54, sealing resin 60, and the like. The light emitting device 10 is a side-view type light emitting device that emits light in a side surface direction (side surface light emitting device).

[0050] The light emitting device 10 has an elongated and flat shape. With respect to the center line (reference line) L that bisects the longitudinal direction, the members (housing 20, lead frames 31 to 33, and light emitting elements 41, 42) other than the bonding lines 51 to 54 are arranged and formed in a linear symmetrical configuration .

[0051] The housing (encapsulation portion) 20 has an elongated and flat box shape, and is integrally formed by synthetic r...

no. 2 approach )

[0097] As shown in FIG. 3 , the light-emitting device 100 of Embodiment 2 is a side-view type light-emitting device, which includes a case 20 (opening portion 20a, bottom surface 20b, inner side surfaces 20c, 20d, accommodating recessed portion 20e, and cylindrical portion 20f), lead frames 31 to 33, light emitting elements 41, 42, bonding wires 51 to 54, sealing resin 60, and the like.

Embodiment approach 2

[0098] The case 20 in Embodiment 2 is the same as the case 20 in Embodiment 1. As shown in FIG. Therefore, an oblique view of the light emitting device 100 is similar to the light emitting device 10 in Embodiment 1 as shown in FIG. 1 .

[0099] Embodiment 2 differs from Embodiment 1 in that the light emitting elements 41, 42 are not arranged in a linear asymmetric configuration with respect to the center line L, and the distance from the light emitting device 41 to the inner side surface 20c of the housing 20 is shorter than from the light emitting device 41 to the inner surface 20c of the casing 20. The distance from the device 42 to the inside surface 20c.

[0100]That is, in Embodiment 2, the light emitting device 41 is arranged in a region close to the inner side surface 20c of the case, and the light emitting device 42 is arranged in a region near the inner side surface 20c of the case.

[0101] In Embodiment 2, exactly as in Embodiment 1, the outer surfaces of the lead ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com