Battery having a cooling plate and motor vehicle having a corresponding battery

A technology for motor vehicles and cooling plates, which is applied in battery/battery traction, electric vehicles, vehicle energy storage, etc. It can solve the problem that the battery module cannot be fixed in advance, achieve small thermal contact resistance, realize heat export, and simplify installation The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

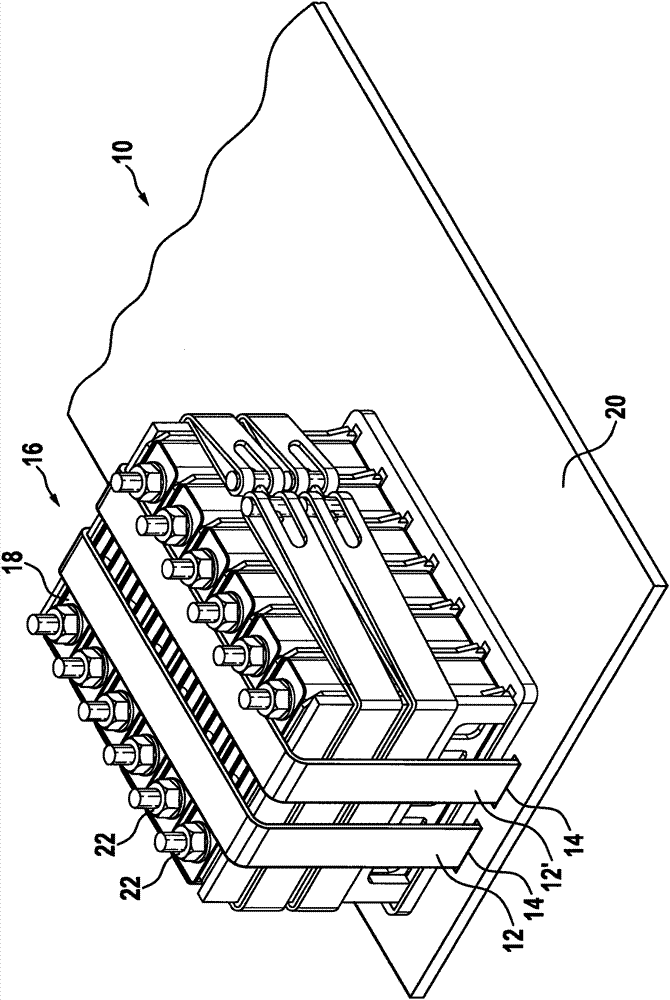

[0020] exist figure 1 An example of a cooling plate 10 according to the invention is shown in . This cooling plate has an upper side 20 . Here, two fixing straps are arranged on the cooling plate 10, a first fixing strap 12 and a second fixing strap 12'. The battery modules 16 are fastened on the top side 20 of the cooling plate 10 by means of said fastening straps 12, 12'. The battery module 16 preferably consists of a plurality of battery cells 18 arranged in series. The bottom side of the battery module 16 is preferably designed in such a way that the bottom side of the battery module 16 lies flat against the top side 20 of the cooling plate 10 .

[0021] The cooling plate 10 serves to regulate the temperature of at least one battery module 16 . For this reason, the cooling plate 10 is preferably made of metal, since metal has a high thermal conductivity. After assembly, the battery modules 16 are directly in contact with the cooling plate 10 . Preferably, the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com