A press-type dental floss stick that can increase the area based on the combination of deflection angles

An area-increasing, pressing-type technology, used in dental flossing, dentistry, cleaning teeth, etc., can solve the problems of wasted replacement of dental floss, less contact area between dental floss and teeth, waste of dental floss, etc., to increase the contact area, The effect of reducing the overall sense of space and protecting the gums

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

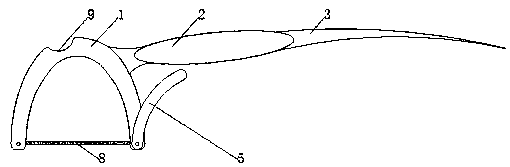

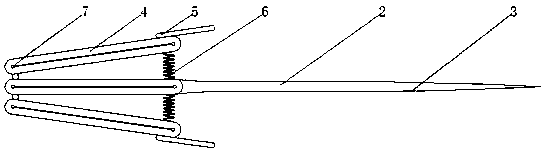

[0028] Such as Figure 1-2 As shown, a press-type dental floss stick that can increase the area based on the combination of deflection angles, including the main wire frame 1, the handle 2 and the toothpick stick 3, the main wire frame 1, the handle 2 and the toothpick stick 3 are from left to right Formed in one piece sequentially, the front and rear sides of the main frame 1 are fixedly connected to the side frame 4 through its left leg, the angle between the main frame 1 and the two groups of side frames 4 is 30 degrees, and the two groups of side frames 4 The right leg is fixedly connected with an arc-shaped pressing handle 5 close to the handle 2, and a buffer spring 6 is fixedly connected between the right leg of the main wire frame 1 and the right legs of the two groups of side wire frames 4, and the main wire frame 1 and the two groups of side wires Dental floss 8 is fixedly connected between the left and right legs of the frame 4, which increases the contact area with...

Embodiment 2

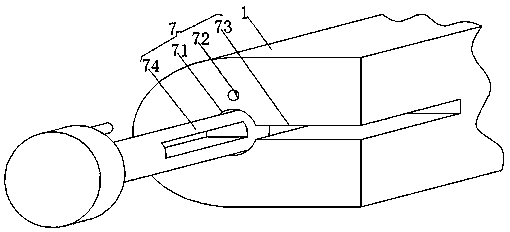

[0030] Such as image 3 As shown, on the basis of Embodiment 1, a connection mechanism 7 is also included. The connection mechanism 7 includes a slot 71, a fixing groove 72 and a limit groove 73. The bottoms of the left and right legs of the main wire frame 1 are provided with interconnected plugs. Groove 71 and limiting groove 73, and limiting groove 73 is located in the inner side of main wire frame 1 and is open shape, and the bottom of main wire frame 1 left and right legs is also provided with the fixed groove 72 that is positioned at slot 71 side.

Embodiment 3

[0032] Such as Figure 4As shown, on the basis of Embodiment 2, a wire fixing mechanism 74 is also included. The wire fixing mechanism 74 is inserted into the slot 71. The wire fixing mechanism 74 includes a pressing column 741, a connecting column 742, a threading groove 743 and a fixing column 744. , the connecting column 742 is inserted into the slot 71, the bottom of the connecting column 742 is integrally formed with a pressing column 741, and the top of the pressing column 741 is welded with a fixing column 744 inserted in the fixing groove 72 and located on one side of the connecting column 742, And the connecting column 742 is provided with a threading groove 743, the threading groove 743 is connected with the dental floss 8, after the dental floss 8 is connected with the threading groove 743, the dental floss 8 is placed in cooperation with the limit groove 73, and the connecting column 742 is stuck into the slot 71, the redundant dental floss 8 plays the effect of in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com