Pan granulation atomization dust collector

A dust removal device, disc granulation technology, applied in the direction of granulation in rotating disc/pan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

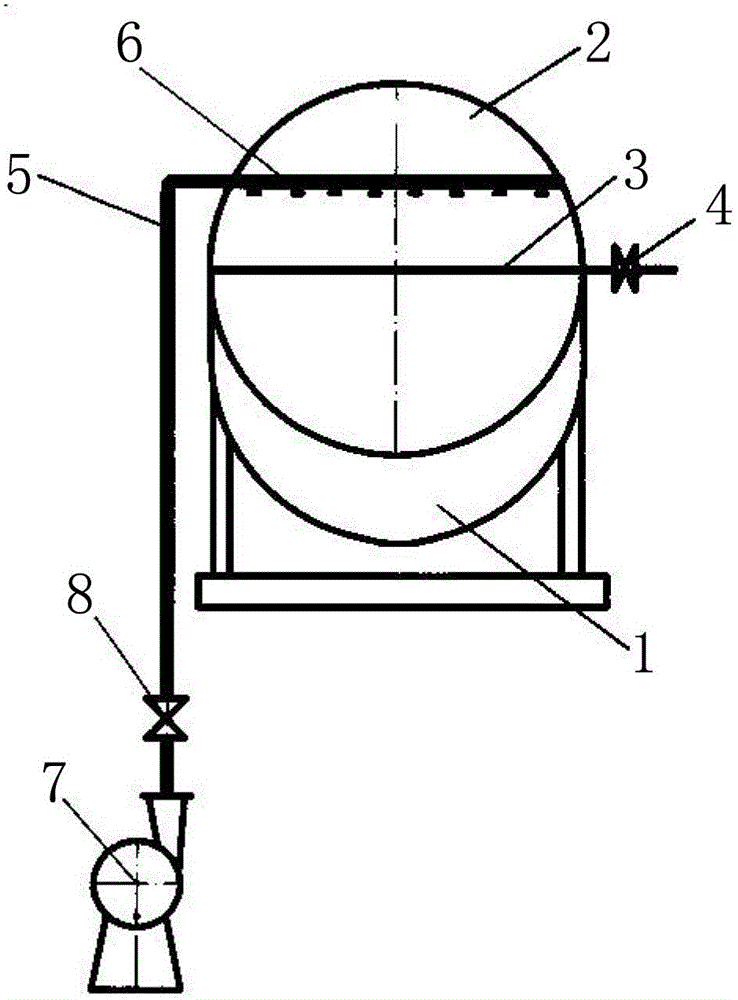

[0009] Such as figure 1 As shown, the present invention is horizontally provided with a water supply pipe 3 in the middle part of the tank body 2 of the disc granulator 1, and is provided with a first adjustment switch 4 at one end of the water supply pipe 3, and passes through the pipeline 5 in the top of the tank body 2 in the horizontal direction. A plurality of high-pressure atomizing nozzles 6 are provided, a high-pressure water pump 7 is connected to the other end of the pipeline 5, and a second regulating switch 8 is provided on the pipeline 5. Through the above settings, when adding water to the fertilizer granulation, the water forms high pressure through the high-pressure water pump 7, and the second regulating switch 8 is adjusted so that the water passes through the high-pressure atomizing nozzle 6 to form a high-pressure water mist, which is sprayed on the upper part of the material in the tank body 2 , to prevent dust from spreading, and then according to the amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com