Load bearing grid plate and preparation method thereof as well as auxiliary refrigeration floor module

A technology of auxiliary refrigeration and grille plate, applied in the field of floor, can solve problems such as poor heat dissipation effect, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

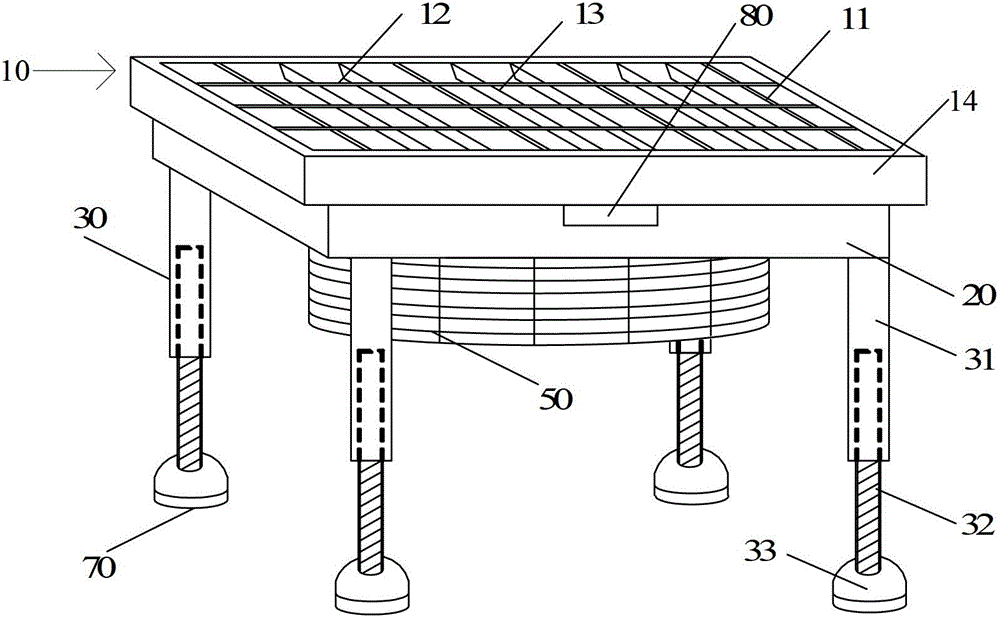

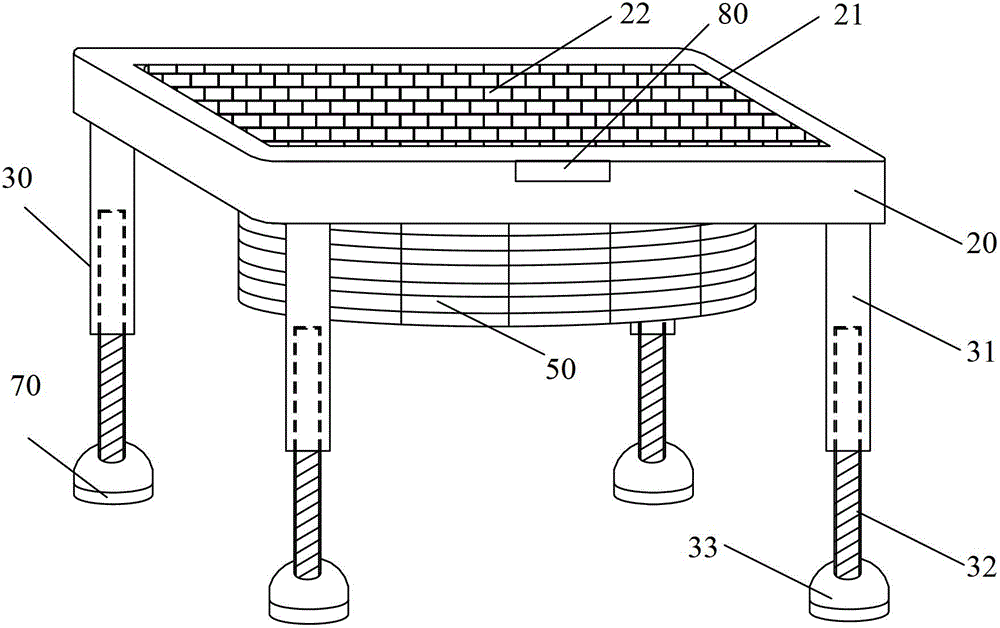

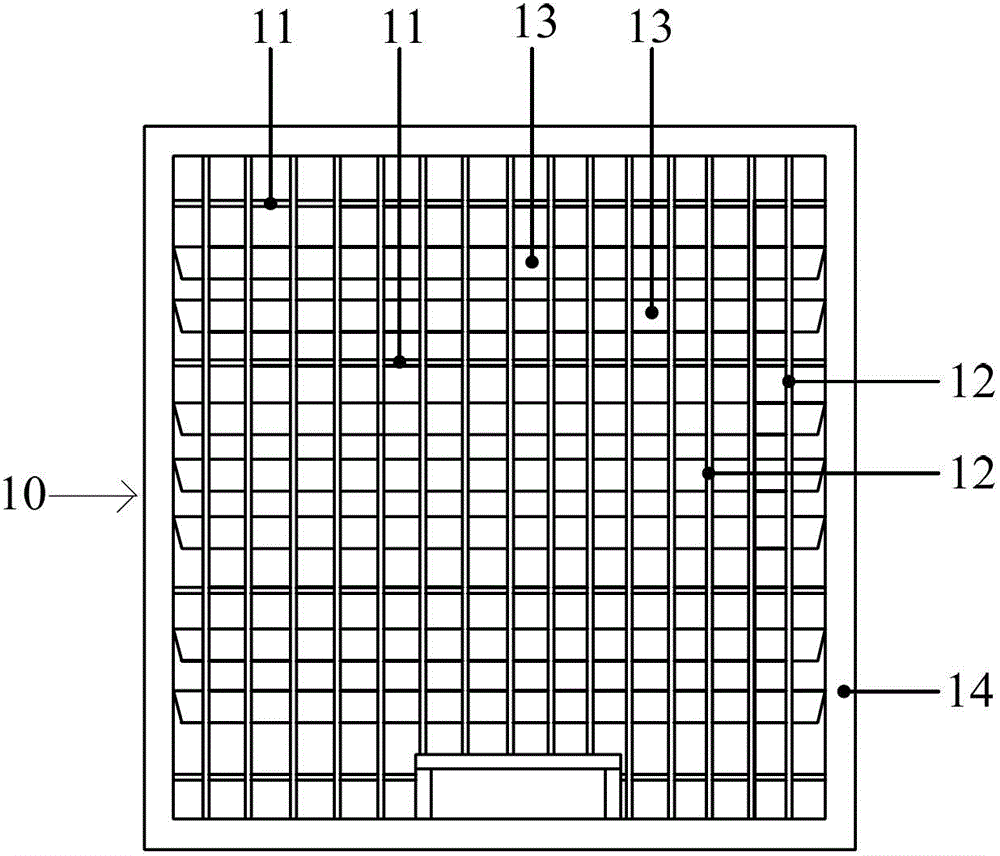

[0033] see Figure 1-3 , the auxiliary refrigeration floor module of the present invention includes a load-bearing grid plate 10, a bracket and a fan. The bracket includes a horizontal support frame 20 and four telescopic support feet 30. The grid plate 10 is arranged above the supporting frame, and the fan is fixedly arranged below the horizontal supporting frame 20, and several adjusting grid strips which can adjust the air outlet direction are arranged in the load-bearing grid plate. When in use, set the auxiliary cooling floor module with adjustable wind direction and height on the periphery of the ground where the equipment (not shown) is located, make the load-bearing grille 10 flush with the ground, and turn on the fan to speed up the air convection around the equipment , so as to quickly take away the hot air around the equipment, effectively reduce the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com