Conveniently-assembled combined shaft

A combined shaft, convenient technology, applied in the direction of shafts, couplings, shafts and bearings, etc., can solve the problems of heavy dismantling workload, increased equipment damage, increased workload, etc., to reduce disassembly, improve service life, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

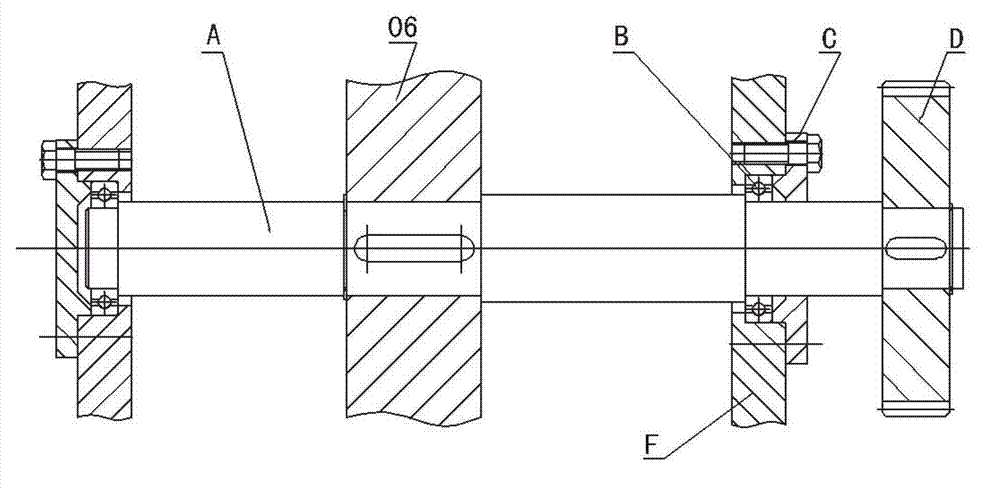

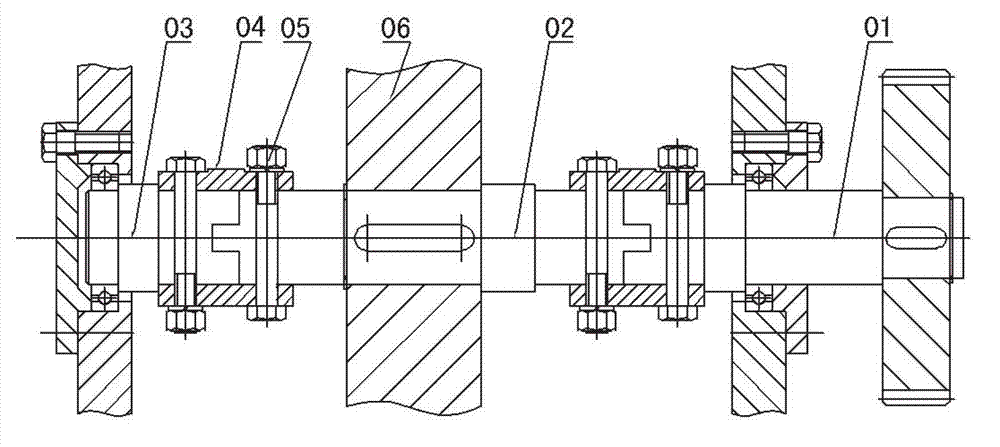

[0017] see figure 2 In this embodiment, the combined shaft for easy disassembly and assembly is composed of the transmission shaft 01 and the coupling shaft 03 located at both ends, and the intermediate shaft 02 located between the transmission shaft 01 and the coupling shaft 03 respectively through the keyway at the shaft end and the split shaft sleeve 04 It is connected as a whole with the bolt 05, and the workpiece 06 is installed on the intermediate shaft 02.

[0018] In specific implementation, the two ends of the intermediate shaft 02 are processed with protruding keys, and the drive shaft 01 and the coupling shaft 03 that cooperate with the intermediate shaft 02 are processed with key grooves at the shaft ends, and the protruding keys are transitionally matched with the key grooves; 02. The transmission shaft 01 and the coupling shaft 03 are provided with through holes corresponding to the positions of the bolt holes on the split shaft sleeve 04, that is, there are key...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com