Multi-degree-of-freedom pitch circle inner-meshing circular moving transmission device

A transmission and internal meshing technology, applied in transmissions, transmission parts, gear transmissions, etc., can solve the problems of easy radial displacement, increase transmission resistance, and single tooth insertion too deep, and achieve good sports performance and Reliability, solving radial displacement, eliminating the effect of radial displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The purpose of the present invention will be further described in detail through specific examples below, and the examples cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following examples.

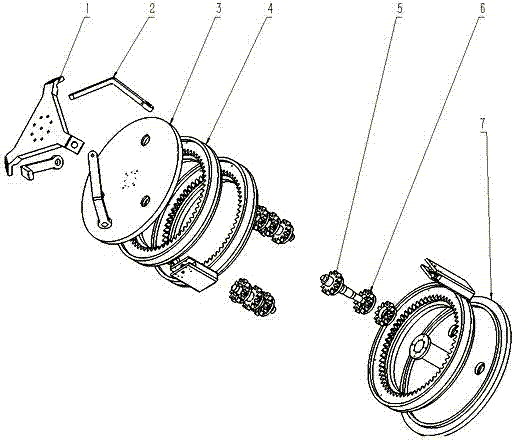

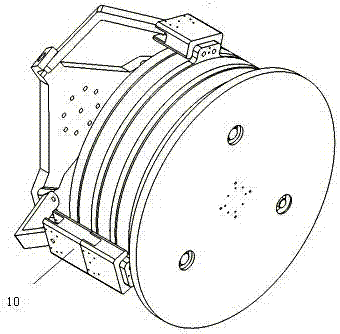

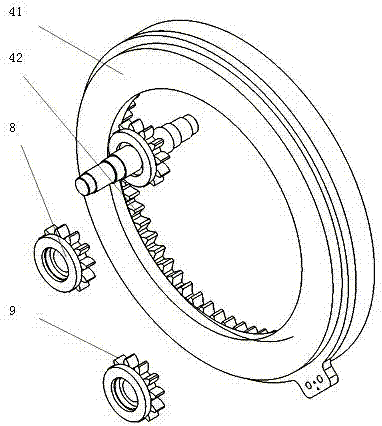

[0033] Such as Figure 1 to Figure 4 As shown, a multi-degree-of-freedom pitch circle internal meshing ring type mobile transmission device is characterized in that: from top to bottom, it includes a parallel ball joint upper platform 1, a fixed upper cover 3, three outer ring internal gears 4, and a device The lower platform 7, the fixed upper top cover 3, each outer ring internal gear 4 and the lower platform 7 of the device are located on the same axis, and the lower platform 7 of the device is centered with a support column that is connected and fixed by screws to fix the upper cover 3. The outer peripheral edges of the two outer ring internal gears 4 are respectively provided with a connecting portion 10, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com