Plate sheet used for waste heat recycling device

A waste heat recovery device and plate technology, used in heat exchange equipment, lighting and heating equipment, laminated components, etc., can solve the problem of poor uniformity of medium distribution, easy occurrence of dead zones, and inability to balance heat transfer and pressure. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with accompanying drawing.

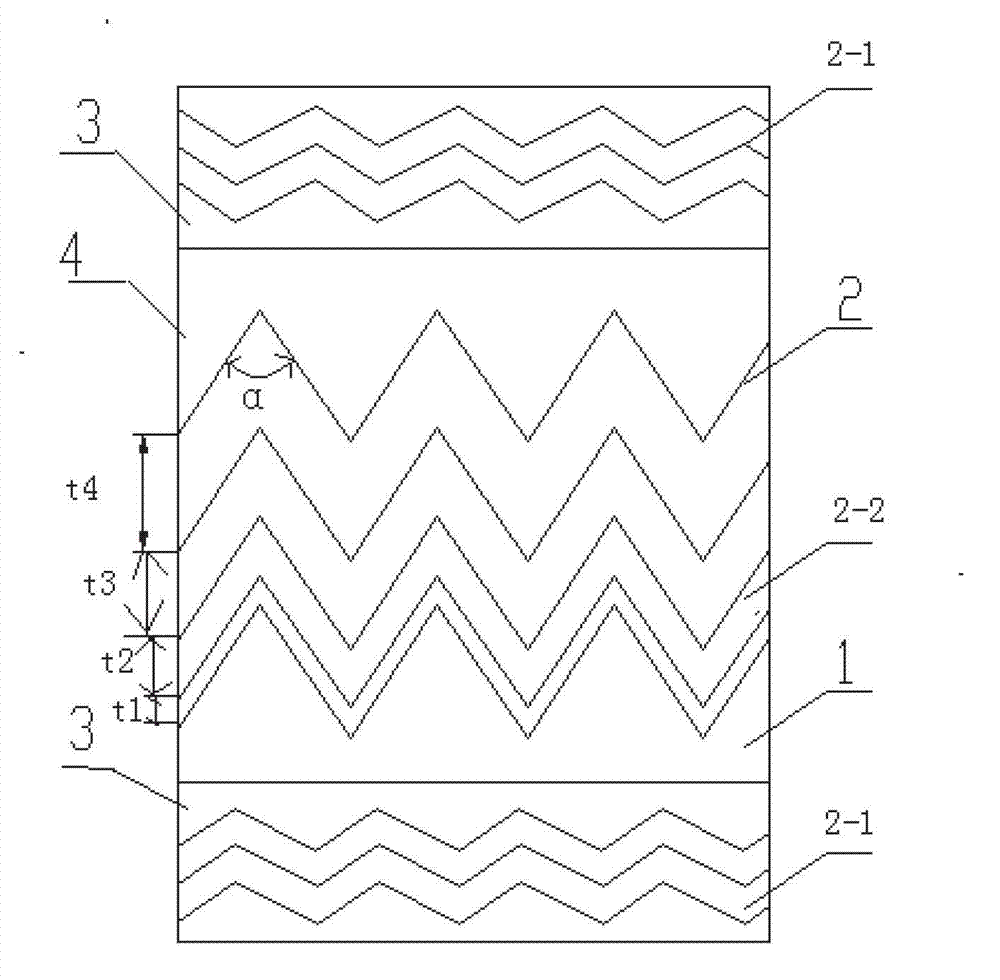

[0008] In order to solve the above technical problems, a plate for a waste heat recovery device was invented, including a plate body 1, the plate body 1 is divided into a distribution area 3 and a heat transfer area 4, and the distribution area 3 and the heat transfer area 4 are respectively Corrugations 2 are provided, and the corrugations 2 include a first group of corrugations 2-1 distributed in the distribution area 3 at both ends of the plate body 1 and a second group of corrugations 2-2 distributed in the heat transfer area 4 of the plate body 1, wherein the The distances t1, t2, t3 and t4 between adjacent corrugations of the corrugations 2-2 in the heat transfer zone 4 are arranged in descending order. Since the distances between the corrugations 2-2 of the heat transfer zone 4 are arranged in order from small to large, after the medium enters the heat transfer zone,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com