Method for electrolytically preparing magnetic copper powder

A copper powder and magnetic technology, applied in the direction of coating, etc., can solve the problems of insufficient uniformity and density of copper powder, easy occurrence of dead zone and coagulation, and easy agglomeration of particles in dead zone, so as to facilitate large-scale industrial application and facilitate adhesion Electroplating, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

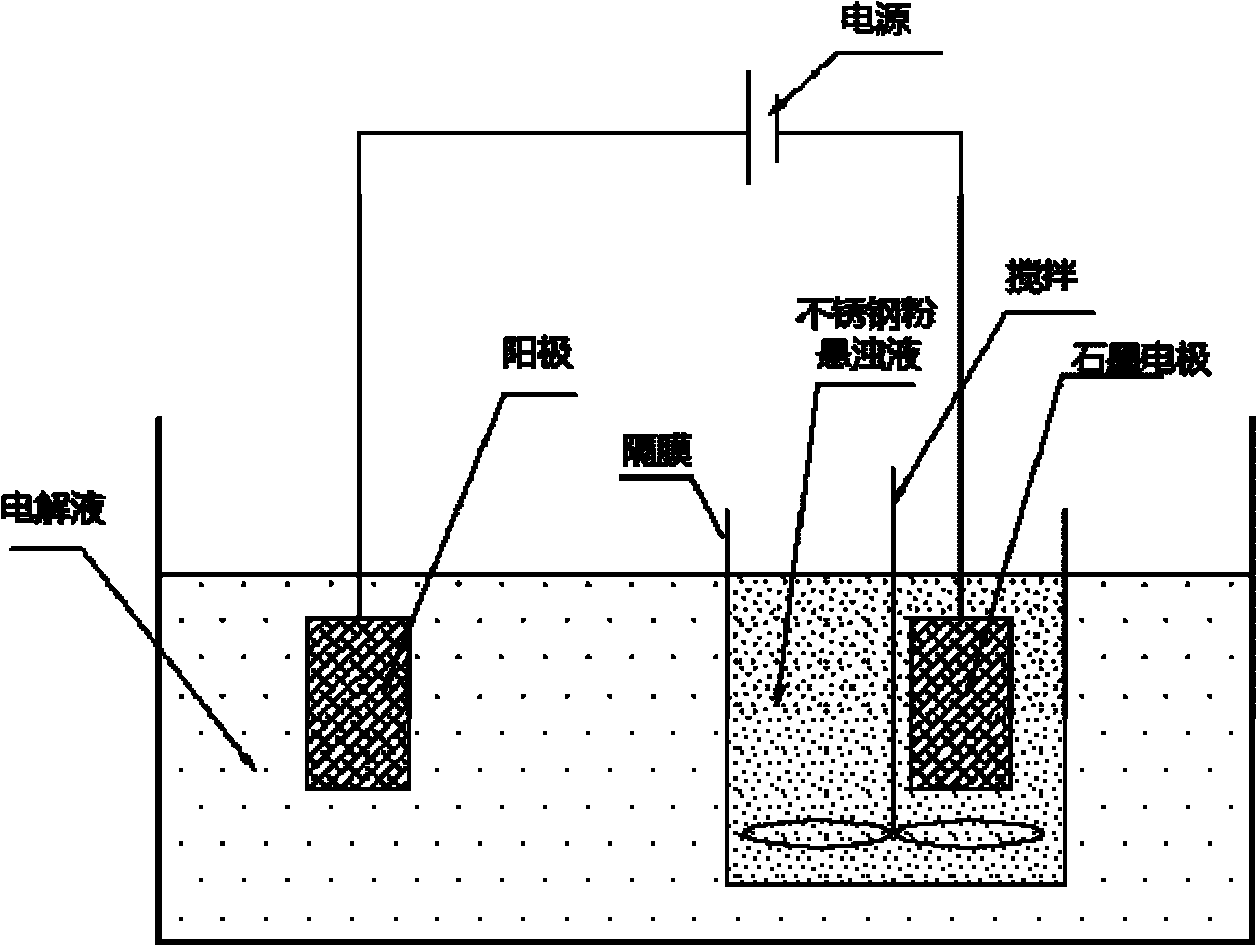

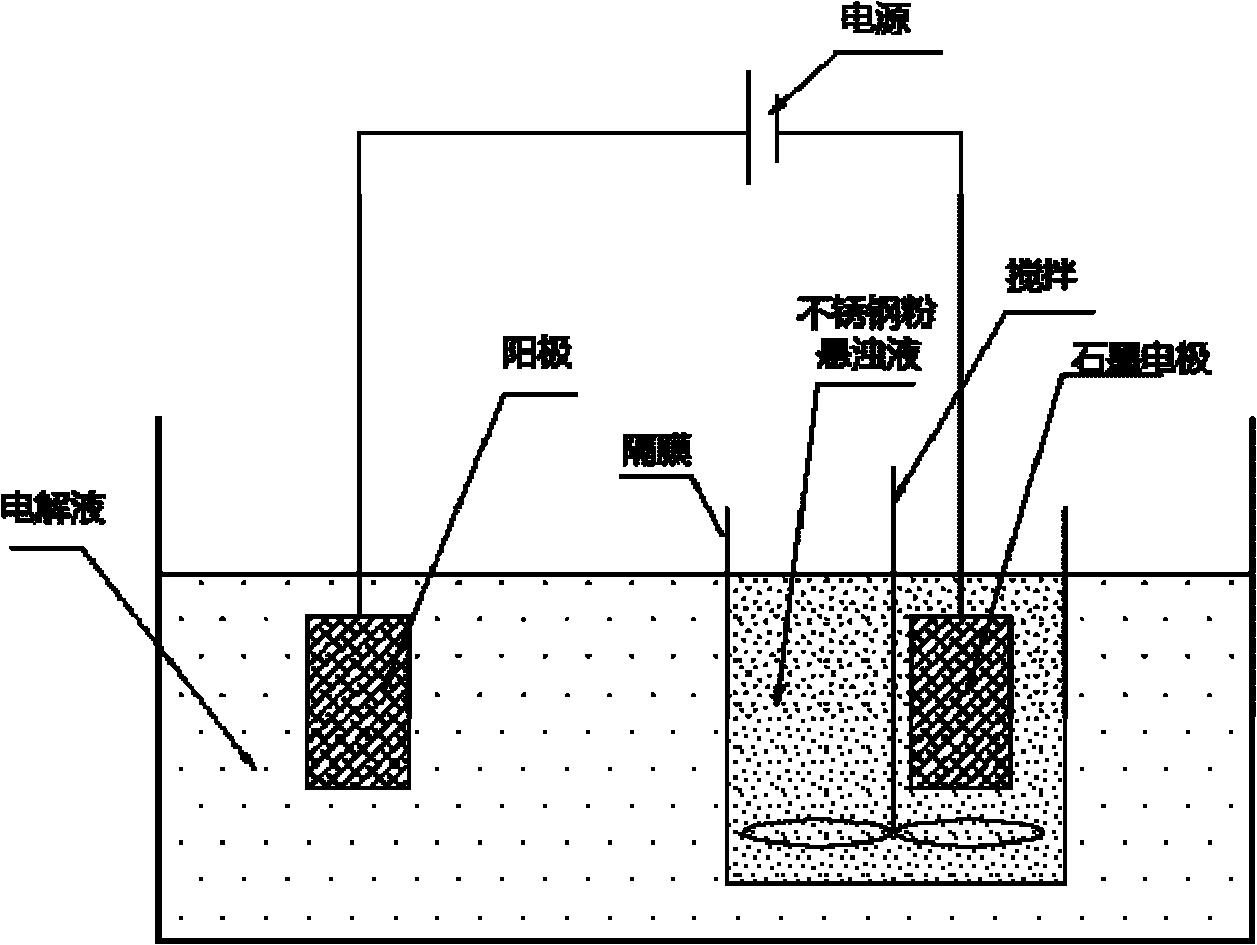

[0024] A mixed solution of sulfuric acid and copper sulfate was configured as the electrolyte, the concentration of copper sulfate in the electrolyte was 50g / L, the pH value was adjusted to 3 with sulfuric acid, and the temperature of the electrolyte was adjusted to 20°C.

[0025] Select an insulating and acid-resistant diaphragm (the diameter of the diaphragm is smaller than the particle size of the stainless steel), make the diaphragm chamber into a cylindrical shape, and put it into the electrolyte; put the stirrer into the diaphragm chamber, close to the bottom wall of the diaphragm chamber, and adjust the speed to 50r / min Add acid-resistant, wear-resistant and magnetic stainless steel powder to form a suspension with a stainless steel powder concentration of 100g / L to ensure that the stainless steel powder is in a fluid state; put the graphite electrode into the suspension.

[0026] Graphite is placed in the electrolyte outside the diaphragm as the anode.

[0027] Turn on...

Embodiment 2

[0030] A mixed solution of sulfuric acid and copper sulfate was configured as the electrolyte, the concentration of copper sulfate in the electrolyte was 100g / L, the pH value was adjusted to 5 with sulfuric acid, and the temperature of the electrolyte was adjusted to 30°C.

[0031] Select an insulating and acid-resistant diaphragm (the diameter of the diaphragm is smaller than the particle size of the stainless steel), make the diaphragm chamber into a cylindrical shape, and put it in the electrolyte; put the stirrer in the diaphragm chamber, close to the bottom wall of the diaphragm chamber, and adjust the speed to 100r / min Add acid-resistant, wear-resistant and magnetic stainless steel powder to form a suspension with a stainless steel powder concentration of 200g / L to ensure that the stainless steel powder is in a fluid state; put the graphite electrode into the suspension.

[0032] Graphite is placed in the electrolyte outside the diaphragm as the anode.

[0033] Turn on t...

Embodiment 3

[0036] A mixed solution of sulfuric acid and copper sulfate is configured as the electrolyte, the concentration of copper sulfate in the electrolyte is 150g / L, the pH value of the electrolyte is adjusted to 7, and the temperature of the electrolyte is adjusted to 45°C.

[0037] Select an insulating and acid-resistant diaphragm (the diameter of the diaphragm is smaller than the particle size of the stainless steel), make the diaphragm chamber into a cylindrical shape, and put it in the electrolyte; put the stirrer in the diaphragm chamber, close to the bottom wall of the diaphragm chamber, and adjust the speed to 300r / min Add acid-resistant, wear-resistant and magnetic stainless steel powder to form a suspension with a stainless steel powder concentration of 500g / L to ensure that the stainless steel powder is in a fluid state; put the graphite electrode into the suspension.

[0038] Graphite is placed in the electrolyte outside the diaphragm as the anode.

[0039] Turn on the D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com