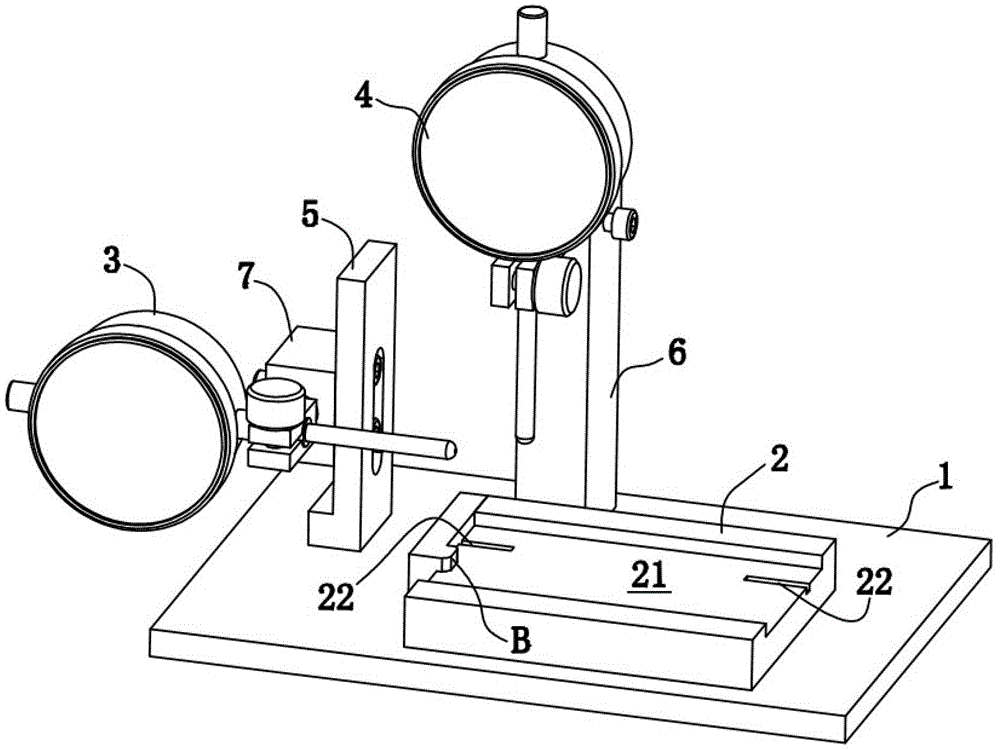

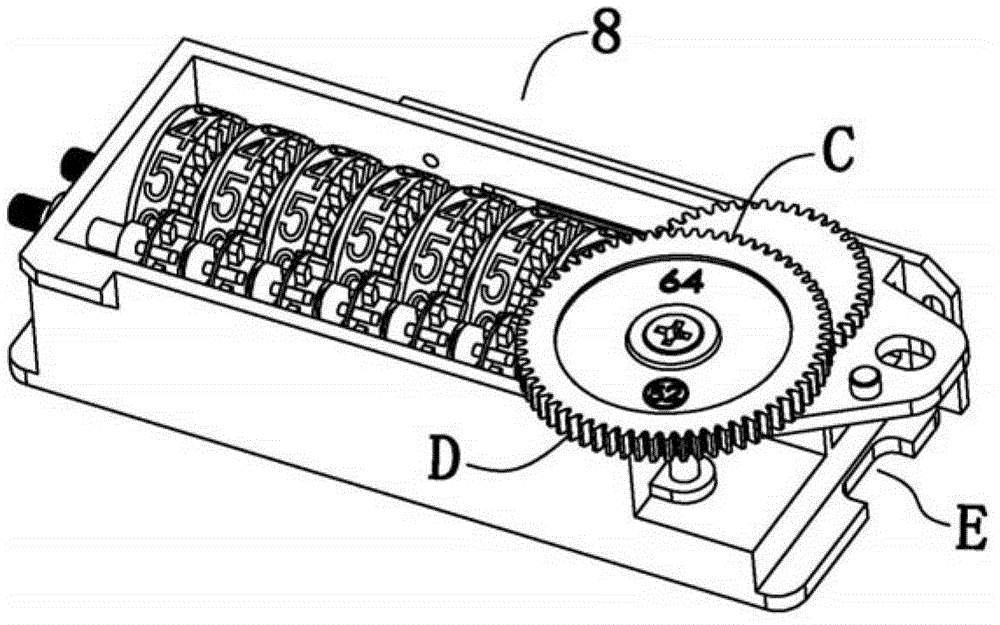

Device for detecting oscillating quantity of adjusting gear of counter

A detection device and counter technology, which is applied to measurement devices, mechanical measurement devices, testing/calibration devices, etc., can solve problems such as affecting gear transmission, increase in gear transmission friction, poor measurement stability of gas meters, etc., and achieve improved stability. , to ensure a balanced, easy-to-promote effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] First of all, I will explain the "diameter indicator" repeatedly mentioned in the present invention. The indicator is a kind of measuring tool. Its English translation is Dial Indicators. It is a universal length measuring tool made of precision rack and pinion mechanism. It is usually composed of measuring head, measuring rod, shockproof spring, rack, pinion, hairspring, round dial and pointer. The dial indicator was made by B.C. Ames in the United States in 1890. It is often used for length measurement of shape and position errors and small displacements. At present, the dial of the commonly used dial indicator is printed with 100 equal division scales, that is, each division value is equivalent to the movement of the measuring rod by 0.01 mm. If there are 1000 equal division scales printed on the round dial, each division value is 0.001 mm, and this measuring tool is called a dial indicator. Change the shape of the probe and equip it with the corresponding bracket t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com