Propylene/1-hexene copolymer composition with broad sealing window

A technology of propylene copolymer and composition, which is applied in the direction of coating, etc., and can solve problems such as the contradiction between finished product performance and processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

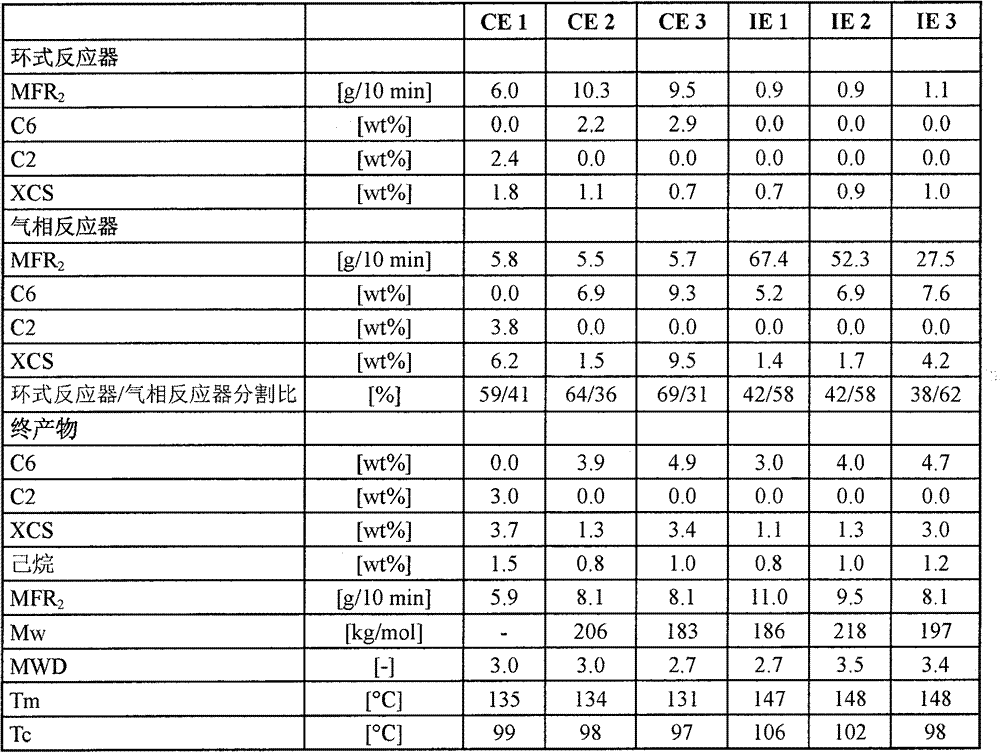

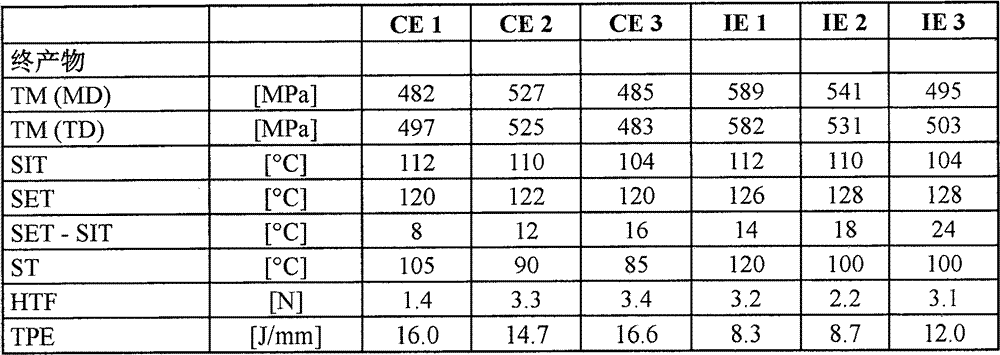

[0097] Furthermore, the present invention relates to a process for the preparation of the propylene copolymer composition (P) of the present invention. Therefore, the process for preparing the propylene copolymer composition (P) as described above is a continuous polymerization process comprising at least two reactors connected in sequence, wherein said process comprises the following steps:

[0098] (A) In the first reactor (R-1), propylene and optionally at least one C 5 -C 12 α-olefins, preferably 1-hexene, are reacted to obtain the polypropylene (A) described in any one of claims 1, 2, 8-10, and the first reactor (R-1) is a slurry reaction device (SR), preferably loop reactor (LR),

[0099] (B) Transfer the polypropylene (A) and unreacted comonomer in the first reactor to the second reactor (R-2), which is a gas phase reaction device (GPR-1),

[0100] (C) combining propylene and at least one C 4 -C 10 α-olefins are fed to the second reactor (R-2),

[0101] (D) In ...

Embodiment

[0197] A. Determination method

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com