Heat-sealing material for polypropylene as well as preparation method and application of heat-sealing material

A polypropylene and copolymerized polypropylene technology, which is applied in the field of compositions based on propylene copolymers, can solve the problems of ultra-low temperature heat-sealing materials sticking to rollers, lowering the material heat-sealing temperature, and easily sticking to rollers, etc. The effect of low sealing temperature, wide heat sealing temperature range and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

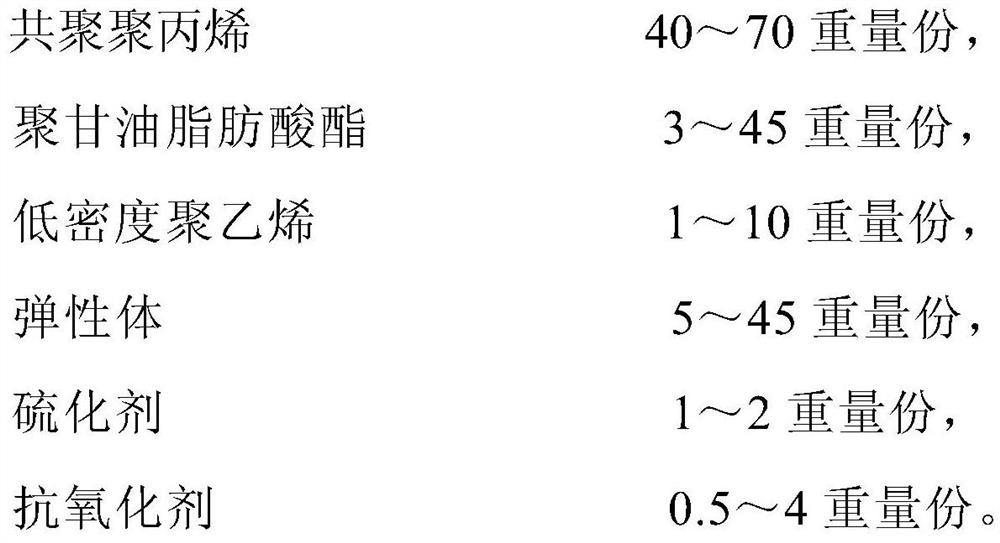

Method used

Image

Examples

Embodiment 1

[0042] (1) Synthesis of polyglycerol fatty acid ester

[0043] 100 parts by mass of rapeseed oil and 25 parts by mass of methanol were reacted with 4 parts by mass of sodium hydroxide for methyl esterification at 70 °C for 4 h, methanol was distilled off at 120 °C, and the upper fatty acid methyl ester was separated, and the lower layer of glycerol continued to Under alkali catalysis, the polymerization was carried out at 210 °C for 10 h, during which the water was discharged through nitrogen to obtain a polyglycerol intermediate, 40 parts by mass of fatty acid methyl esters were added, and further heated to 180 °C, stirred and polymerized for 16 h, and then decompressed (180 °C, 1.33KPa). ) distillation for 5h to obtain polyglycerol fatty acid ester.

[0044] (2) Preparation of heat sealing material

[0045] 60 parts by weight of ethylene propylene butene terpolymer polypropylene (KS350, INEOS, MI 5.0, 131°C), 25 parts by weight of polyglycerol fatty acid ester, 5 parts by w...

Embodiment 2

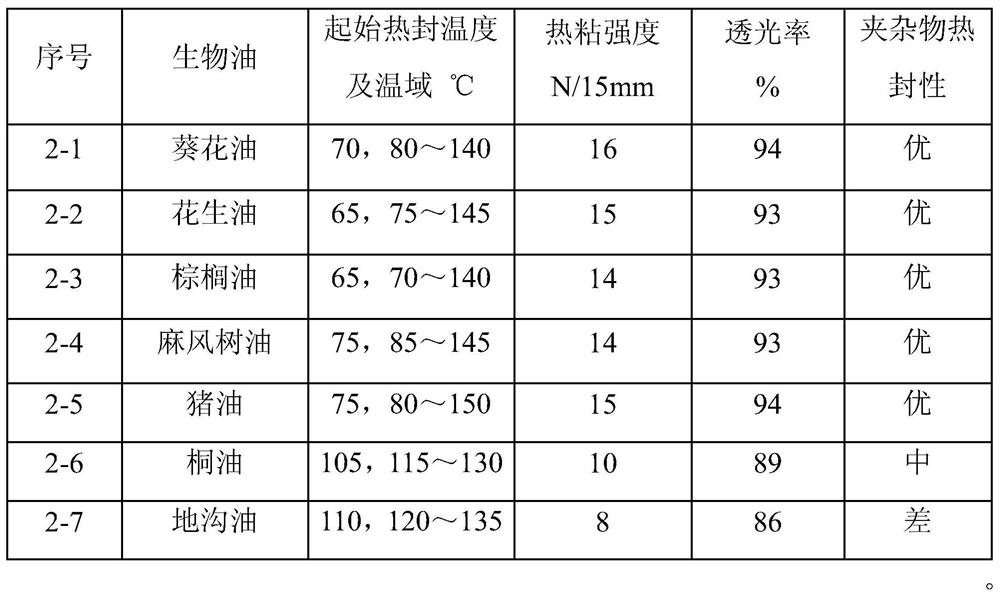

[0051] The method is the same as that of Example 1, except that different bio-oils are selected for the reaction, as shown in Table 1.

[0052] Table 1: Effects of different bio-oils on the properties of heat-sealing materials

[0053]

[0054] The experimental results in Table 1 above show that: when the preparation method of the present application is used to prepare the heat-sealing material, the bio-oil selected in Table 1 can be obtained under the synthesis conditions provided in this case. The polyglycerol fatty acid ester of hydroxyl group and ester group has a good heat sealing effect on the heat sealing material. 65~70℃, the hot tack strength is kept at 14~16N / 15min; the light transmittance is kept at 93~94%. However, the number of double bonds in the tung oil used in the No. 2-6 scheme is large, and it is easy to form a highly cross-linked asphaltene component during the polymerization process, which cannot be entangled with the polypropylene chain. The waste oil...

Embodiment 3

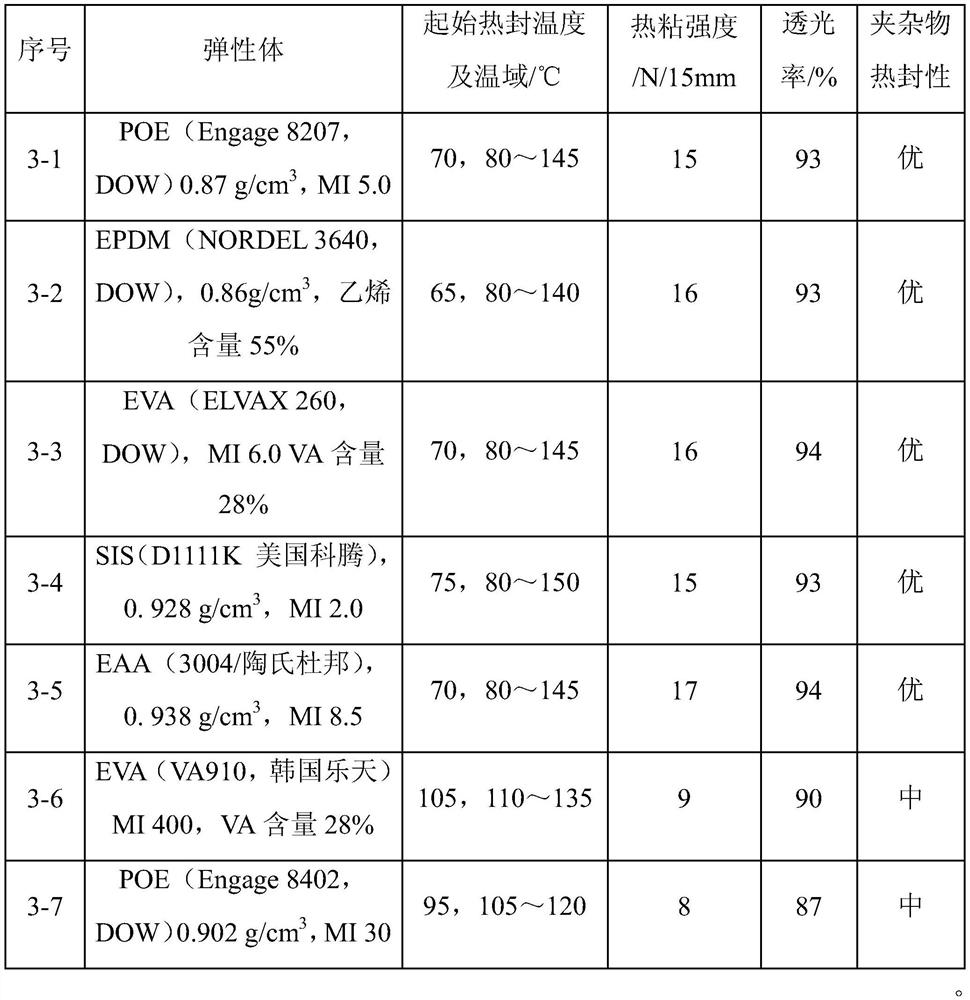

[0064] The method is the same as in Example 1, except that different elastomers are selected for the reaction, as shown in Table 2.

[0065] Table 2: Effects of Different Elastomers on the Properties of Heat Sealing Materials

[0066]

[0067] It can be seen in combination with Table 2: when the preparation method of the present application is used to prepare the heat-sealing material, the selected elastomer has an active component aliphatic chain in its structure and the molecular weight of the copolymer is entangled, giving the heat-sealing material a lower The heat-sealing temperature (65-75℃) and wide temperature range (span about 60-70℃), and the hot-stick strength is basically maintained at 15-17N / 15min, and the light transmittance is also maintained at 93-94%. Compared with Example 1, the elastomer of this example has certain polar components, which can effectively improve the thermal adhesion efficiency of the material. Molecules with too high fluidity (No. 3-6, 3-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com