Method for applying resin poe in pof polyolefin shrink film

A polyolefin and shrink film technology, applied in the field of POF polyolefin shrink film. The effect of improving the degree of protection, improving the ability of the machine and improving the adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

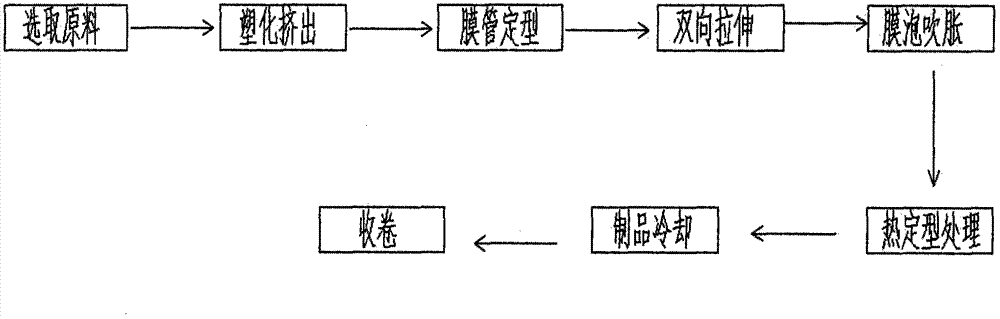

[0039] Such as figure 1 As shown, a method of using resin POE in POF polyolefin shrink film, including raw material ratio and process flow:

[0040] The application technology of a new resin POE in POF polyolefin shrink film, its raw material ratio includes the raw material ratio of the upper and lower surface layers, the raw material ratio of the middle layer and the ratio of processing aids. The raw material ratio of the upper and lower surface layers is POE10%, ternary random copolymer polypropylene 25%, the raw material ratio of the middle layer is eight carbon linear low density polyethylene 45%, ultra low density polyethylene 18%, processing aid 2 %.

[0041] A kind of method that resin POE is applied in POF polyolefin shrinkage film, its technological process is:

[0042] 1. Select raw materials

[0043] Select POE, ternary random copolymer, eight-carbon linear low-density polyethylene, ultra-low-density polyethylene and processing aids, the mass percentage of which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com