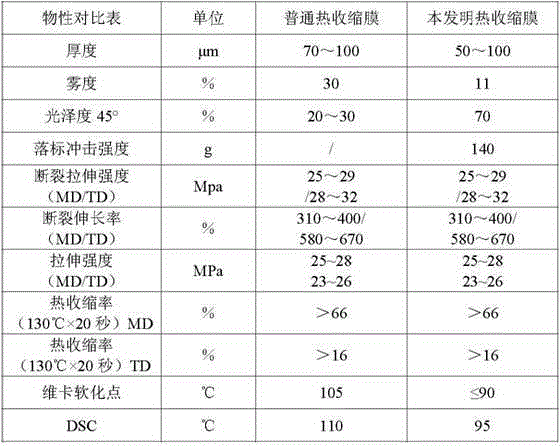

A low-temperature polyethylene shrink film and its blown film process

A low-temperature polyethylene and shrink film technology, applied in flexible coverings, packaging, layered products, etc., can solve the problems of high energy consumption, high shrinkage temperature, product performance, thickness, and strength are not stable enough to achieve temperature control. Accurate, high production efficiency and stable blown film process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A low-temperature polyethylene shrink film, the low-temperature polyethylene shrink film is composed of three layers of co-extruded and bonded films, namely an outer layer, a middle layer and an inner layer;

[0032] The outer layer is composed of 50% high melting point blown film grade polyethylene, 25% coating grade polyethylene, and 25% metallocene polyethylene by weight percentage;

[0033] The middle layer is composed of 50% high-melt finger blown film grade polyethylene, 30% coating grade polyethylene, and 20% metallocene polyethylene by weight percentage;

[0034] The melt index of the high melting point blown film grade polyethylene ≥ 4g / 10min, density ≤ 0.925g / cm 3 , the present embodiment selects the high-melt index blown film grade polyethylene that the model is Yangzi BASF 2420K; The melting index of described coating grade polyethylene ≥ 7g / 10min, density are 0.910g / cm 3 ~0.930g / cm 3 , this embodiment selects the coating grade polyethylene whose model is ...

Embodiment 2

[0043] A low-temperature polyethylene shrink film, the low-temperature polyethylene shrink film is composed of three layers of co-extruded and bonded films, namely an outer layer, a middle layer and an inner layer;

[0044] The outer layer is composed of 70% high melting point blown film grade polyethylene, 5% coating grade polyethylene, and 25% metallocene polyethylene by weight percentage;

[0045] The middle layer is composed of 43% high-melt finger blown film grade polyethylene, 27% coating grade polyethylene, and 30% metallocene polyethylene by weight percentage;

[0046] The melt index of the high melting point blown film grade polyethylene ≥ 4g / 10min, density ≤ 0.925g / cm 3 , the present embodiment selects the 2426K high melting index blown film grade polyethylene that the model is China Sea Shell Petrochemical Co., Ltd; 3 ~0.930g / cm 3 , the present embodiment selects the coating grade polyethylene that model is Mitsui Chemicals 403; Said metallocene polyethylene refers ...

Embodiment 3

[0055] A low-temperature polyethylene shrink film, the low-temperature polyethylene shrink film is composed of three layers of co-extruded and bonded films, namely an outer layer, a middle layer and an inner layer;

[0056] The outer layer is composed of 60% high melting point blown film grade polyethylene, 10% coating grade polyethylene, and 30% metallocene polyethylene by weight percentage;

[0057] The middle layer is composed of 40% high-melt finger blown film grade polyethylene, 25% coating grade polyethylene, and 35% metallocene polyethylene by weight percentage;

[0058] The raw material composition of the inner layer is the same as that of the outer layer;

[0059] The melt index of the high melting point blown film grade polyethylene ≥ 4g / 10min, density ≤ 0.925g / cm 3 , the present embodiment selects the high-melt finger blown film grade polyethylene that model is Dow 5005 for use; The melting index of described coating grade polyethylene ≥ 7g / 10min, density are 0.910...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com