Fluoridation reactor of fixed bed

A technology of reactor and fixed bed, which is applied in the field of reactors for green and environment-friendly fluorinated refrigerants, can solve the problems of difficulty in ensuring the final quality of refrigerants, poor control of the temperature range, and difficulty in ensuring sufficient reaction, etc., to achieve economical improvement. Sex and reliability, shock reduction, and pressure drop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

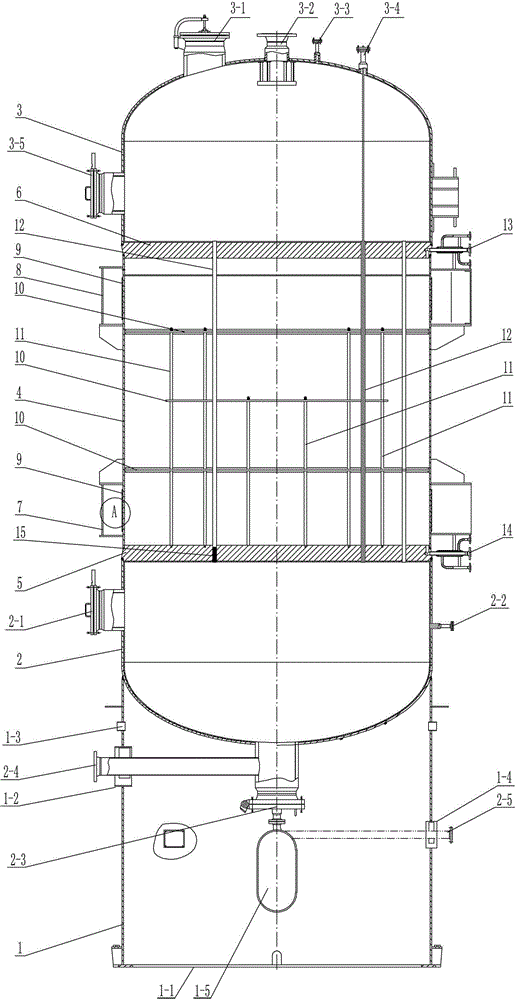

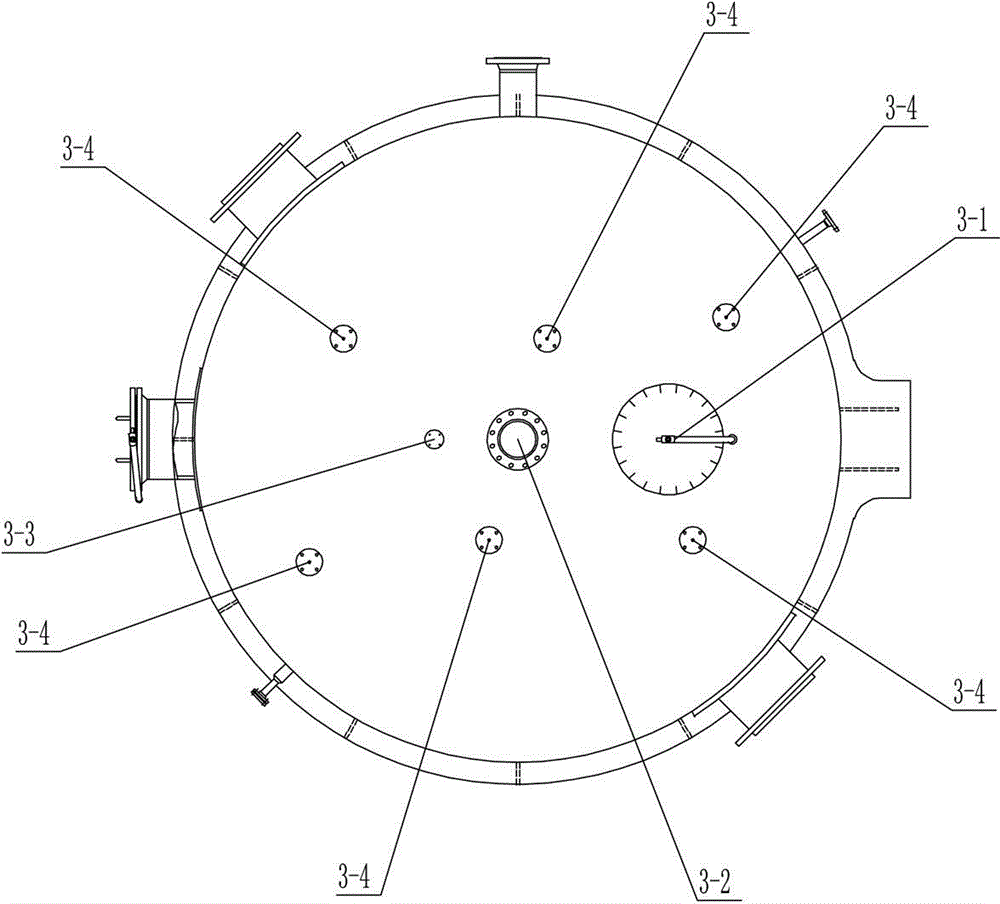

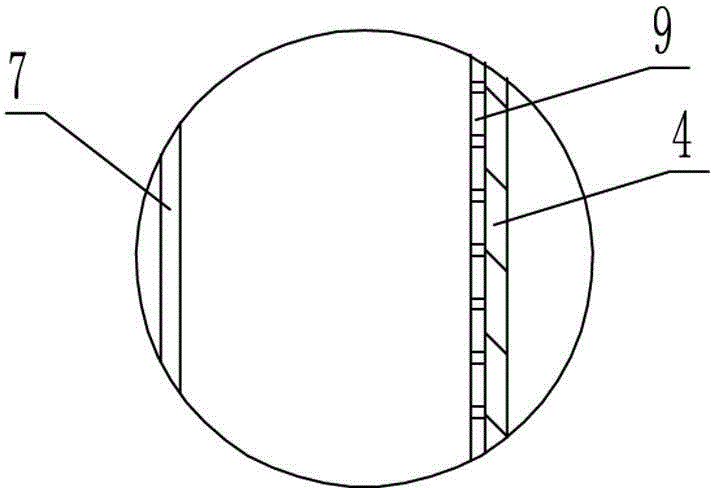

[0025] Such as Figure 1 to Figure 5 As shown, the fixed bed fluorination reactor: consists of skirt (1), lower tube box (2), lower tube plate (5), cylinder body (4), upper tube plate (6) and upper tube box (3) constitute. The lower tube box (2), the lower tube plate (5), the cylinder body (4), the upper tube plate (6) and the upper tube box (3) form a closed reaction vessel.

[0026] The skirt (1) is welded to the lower tube box (2). The lower end of the skirt seat (1) is provided with a foundation ring plate (1-1) so as to be connected with the field foundation. The skirt (1) is provided with a gas outlet outlet pipe (1-2), an exhaust port (1-3), a reserved gas outlet outlet pipe (1-4) and a manhole (1-5).

[0027] The lower pipe box (2) is provided with a manhole port I (2-1), a pressure gauge port I (2-2) and a discharge port (2-3); a gas outlet is provided on the discharge port (2-3) (2-4) and reserved gas outlet spare pipe (2-5). The gas outlet (2-4) passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com