Tool used for replacing side roll resistance torsion bar bushing block of bogie and replacement method

A technology of anti-rolling torsion bar and bogie, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as end shaft damage, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

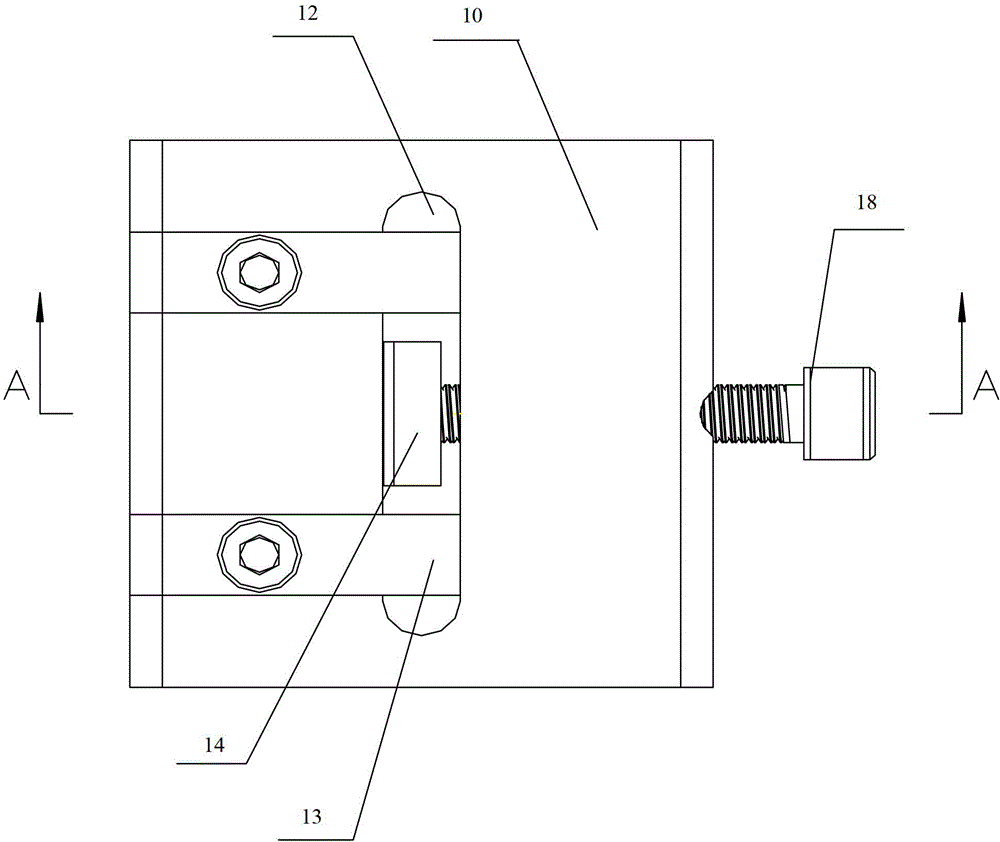

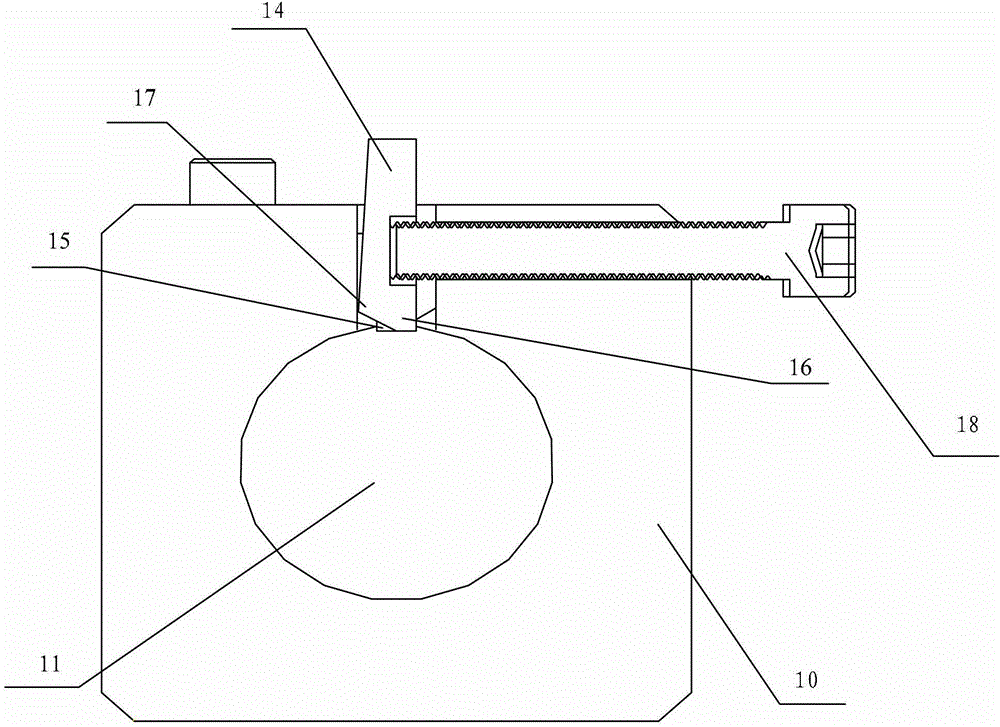

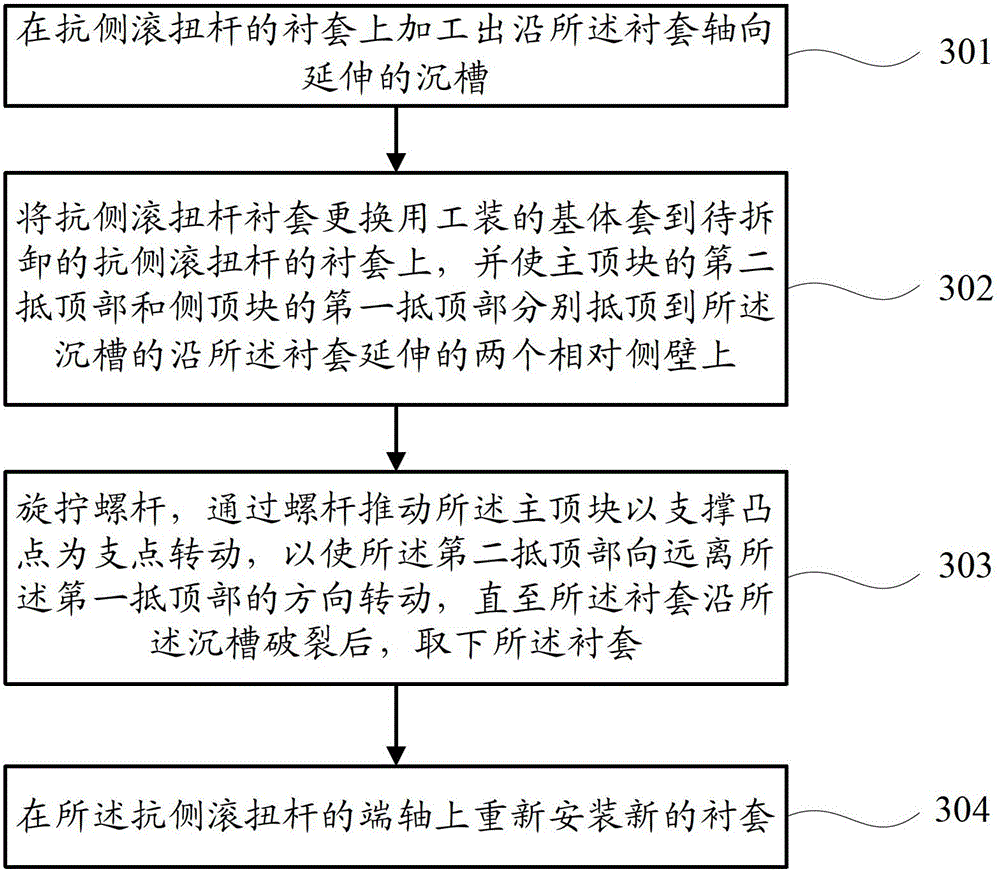

[0021] figure 1 It is a structural schematic diagram of the bogie anti-roll torsion bar bush replacement tooling according to Embodiment 1 of the present invention; figure 2 for figure 1 Schematic diagram of the middle A-A section; Figure 4 is a schematic diagram of the anti-roll bar bushing of the bogie in the installed state; Figure 5 for figure 1 Schematic diagram of the use state of the bogie anti-roll torsion bar bushing replacement tooling in ; please refer to figure 1 , figure 2 , Figure 4 and Figure 5 , the bogie anti-roll torsion bar bush replacement tooling includes: a base body 10, on the base body 10, there is a mounting hole 11 for sheathing on the bushing 20 of the anti-roll torsion bar; An elongated through hole 12 is provided on the surface of the base body 10, the length direction of the elongated through hole 12 is parallel to the central axis of the mounting hole 11, and the bottom of the elongated through hole 12 communicates with the mounting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com