Paper surface groove embossing device

An embossing and groove technology, which is applied in the direction of machining/deformation, can solve the problems of poor synchronization performance between the servo motor of the groove roller and the paper guide motor, easy drift of the filter rod incision, and unstable product quality. Increased pass rate, improved product quality, and stable tooth shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

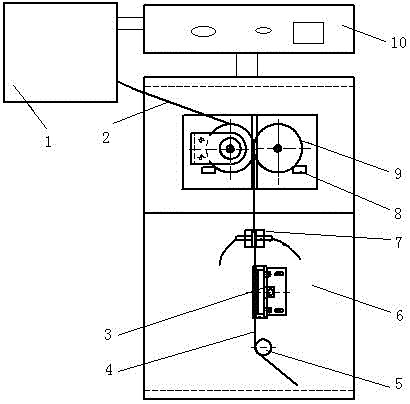

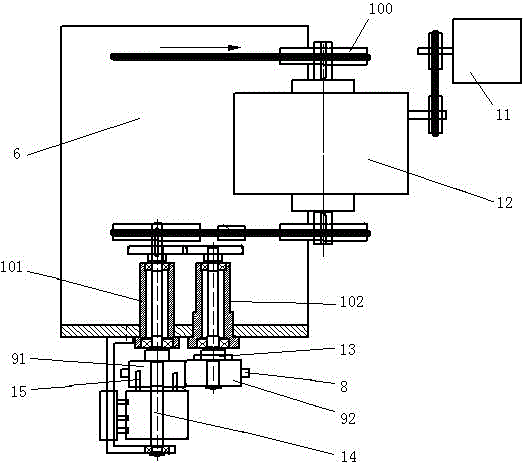

[0030] as attached figure 1 , 2 As shown, the paper surface groove embossing device provided by the present invention consists of an electrical control system 10, a transmission mechanism 100 (powered by the main motor of the filter rod forming machine 1), two matching embossing rollers 9, and a protective cover , paper guide roller 5, mechanism base 6 and other components. Power is introduced from the main motor, and the embossing roller 9 is driven to rotate through the transmission mechanism 100 .

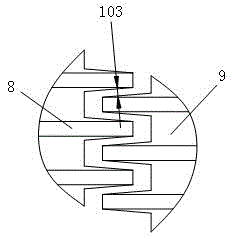

[0031] The rotating shafts 14 of the two embossing rollers 9 are connected to their respective bearing seats. The bearing seat A101 of the embossing roller A91 is fixedly connected to the mechanism base 6. The bearing seat B102 of the embossing roller B92 can be moved to change the two embossing rollers. 9 center distance to adjust and control the embossing depth of the paper tape 4, when the embossing depth is adjusted in place, the bearing seat B102 of the embossing roller B92...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com