Seat back

A seat back and seat technology, applied to vehicle seats, back cushions, armrests, etc., can solve the problems of complex structure, increased number of parts, and reduced ease of assembly, so as to simplify the structure and reduce the number of parts , The effect of improving the ease of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

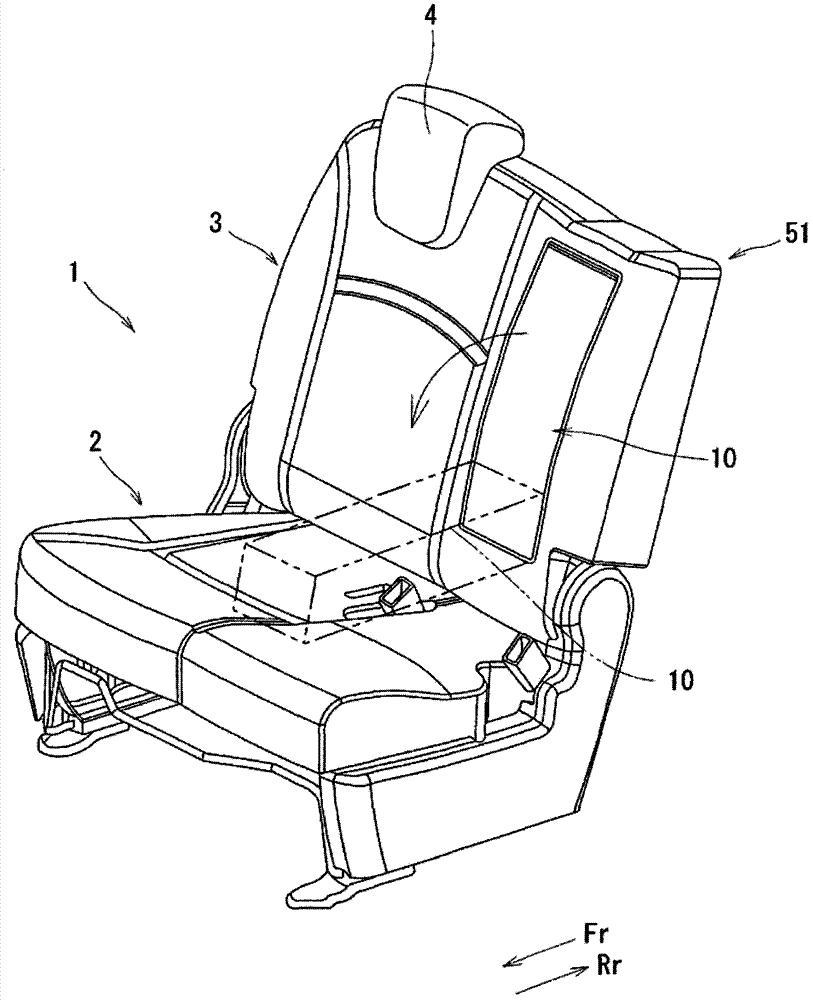

[0077] Embodiments for carrying out the present invention are described below based on the drawings.

[0078] figure 1 A seat 1 of a motor vehicle is shown. The seat 1 includes a seat cushion 2 supporting a passenger's buttocks and thighs, and a seat back 3 supporting a passenger's back. A headrest 4 supporting a passenger's head is connected to an upper end portion of the seat back 3 . An armrest 10 that supports an arm of an occupant is also provided in a left side portion of a seat back main body 51 that is a main body portion of the seat back 3 .

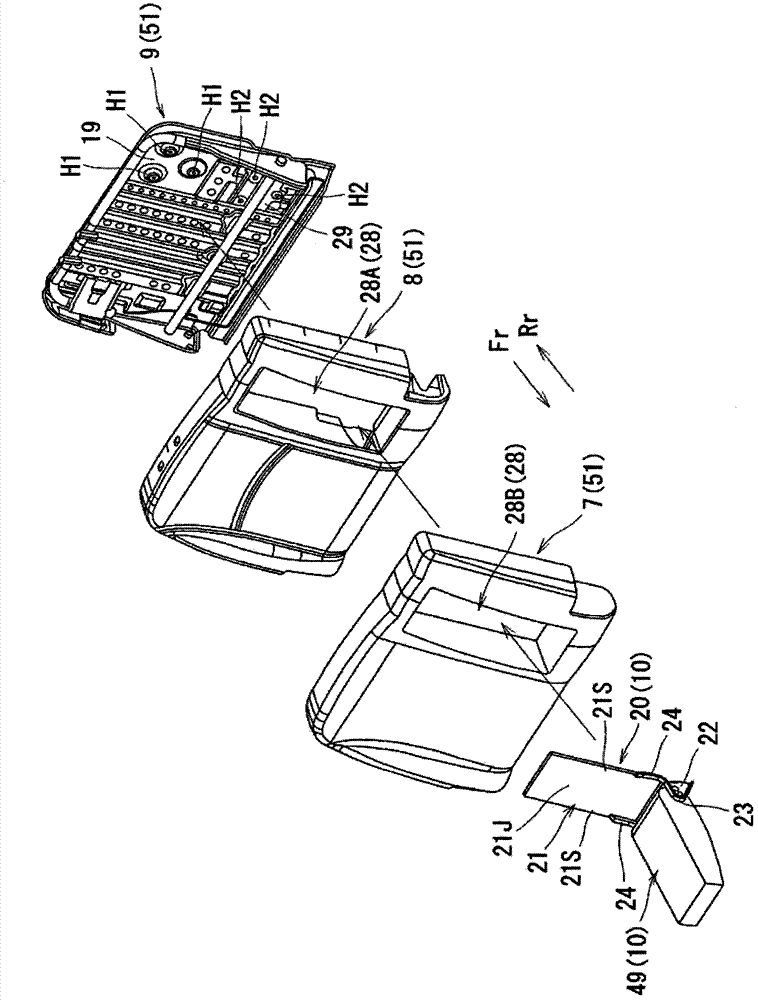

[0079] Structure of the seat back main body 51

[0080] Such as figure 2 As shown in , the seat back main body 51 includes a seat back frame 9 , a seat back pad 8 supported on the seat back frame 9 , and a skin material 7 covering the seat back pad 8 .

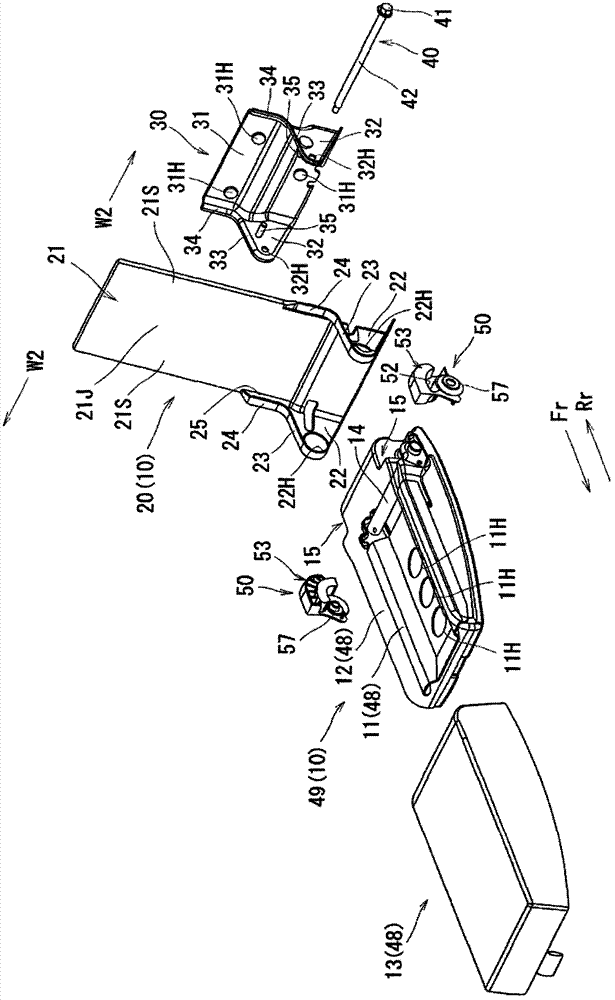

[0081] A storage recess 28 (corresponding to a storage portion) for storing the armrest main body 49 of the armrest 10 is formed in a left side portion of the seat back ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com