Solid composite accelerant for low-temperature methane and preparation method thereof

A composite accelerator and solid technology, applied in the field of agricultural microorganism application, can solve the problems of biogas production in a biogas digester in winter, decomposition of straw can not solve the problem of biogas production in a biogas digester in winter, etc., and achieves the effect of a simple use method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Preparation of Low Temperature Biogas Solid Composite Accelerator

[0027] The present invention is used for the preparation method of low-temperature biogas solid composite accelerator, comprises the following steps:

[0028] (1) Select Bacillus pumilus CICC10440, Lactococcus CICC20711, Pseudomonas ( Pseudomonas sp. ) CGMCC No.4764 and Pantoea agglomerans ( Pantoea agglomerans ) CGMCC No.4765, respectively purify rejuvenation, and obtain fresh pure culture fermentation broth.

[0029] (2) Mix the four pure culture fermentation broths in step (1) according to the mass ratio of 1:1:1:1 to make a liquid composite microbial agent.

[0030] (3) Mix the liquid compound bacterial agent in step (2) with soybean meal and bran of equal mass and mix well, and the soybean meal and bran are mixed in a weight ratio of 1:1.

[0031] (4) Spread the mixture prepared in step (3) in a cool and dry environment to dry in the shade.

[0032] (5) 6%-36% ferric chloride and...

Embodiment 2

[0035] Example 2: Preparation of solid composite microbial agent for biogas low-temperature fermentation

[0036] Bacillus pumilus CICC10440, lactis streptococcus CICC20711, Pseudomonas ( Pseudomonas sp. ) CGMCC No.4764 and Pantoea agglomerans ( Pantoea agglomerans ) CGMCC No.4765 original slant strains of four kinds of bacteria were used as the starting point, and single colonies were obtained by streaking on LB plates, and robust and typical single colonies were picked and transferred to slant surfaces for rejuvenation. Cultivate at 200°C for 24 hours, fill 7 liters of material in a 10 liter fully automatic fermenter, inoculate a liquid shaker flask after sterilization, check under the microscope after 48 hours for no pollution, put it into the tank, and get 7 liters of bacterial liquid; obtain the other two in the same way The bacterial liquid of the strain is mixed with a total of 28 liters. Weigh 28 kg of soybean meal and bran to make a heap in the middle of the site...

Embodiment 3

[0042] Example 3: Low-temperature biogas solid composite accelerator applied to 5 liters of biogas fermentation

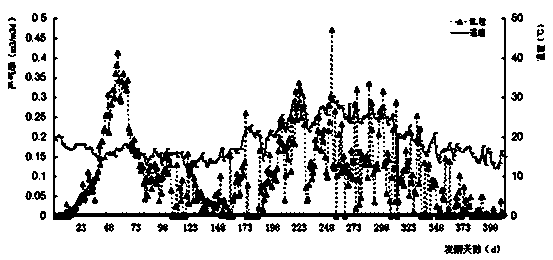

[0043] Weigh 1.5 kg of powdered sheep manure, put it into a 5-liter biogas fermentation device, add 3.5 liters of water, mix well, seal it, and start collecting gas production after seven days at a temperature of 10°C-25°C. After 100 days, the gas production starts to decline , add 2.5 grams of the low-temperature biogas solid composite accelerator of the above-mentioned embodiment, mix well, continue to detect the gas production, and set up a blank control group at the same time; see the attached figure 1 shown.

[0044] Weigh 1.5 kg of powdered sheep manure, put it into a 5 liter biogas fermentation device, add 3.5 liters of water, mix well, seal it, collect gas production after seven days, and add 2.5 grams of the above solid composite bacterial agent when the gas production starts to decline after 100 days , mix well, continue to detect the gas production, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com