Inversion-type cylinder weft yarn unwinding device

An inverted, weft technology, applied in textiles, textiles, papermaking, looms, etc., can solve the problems affecting the quality of finished fabrics and economic benefits of enterprises, and achieve the effect of improving the quality of fabrics and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

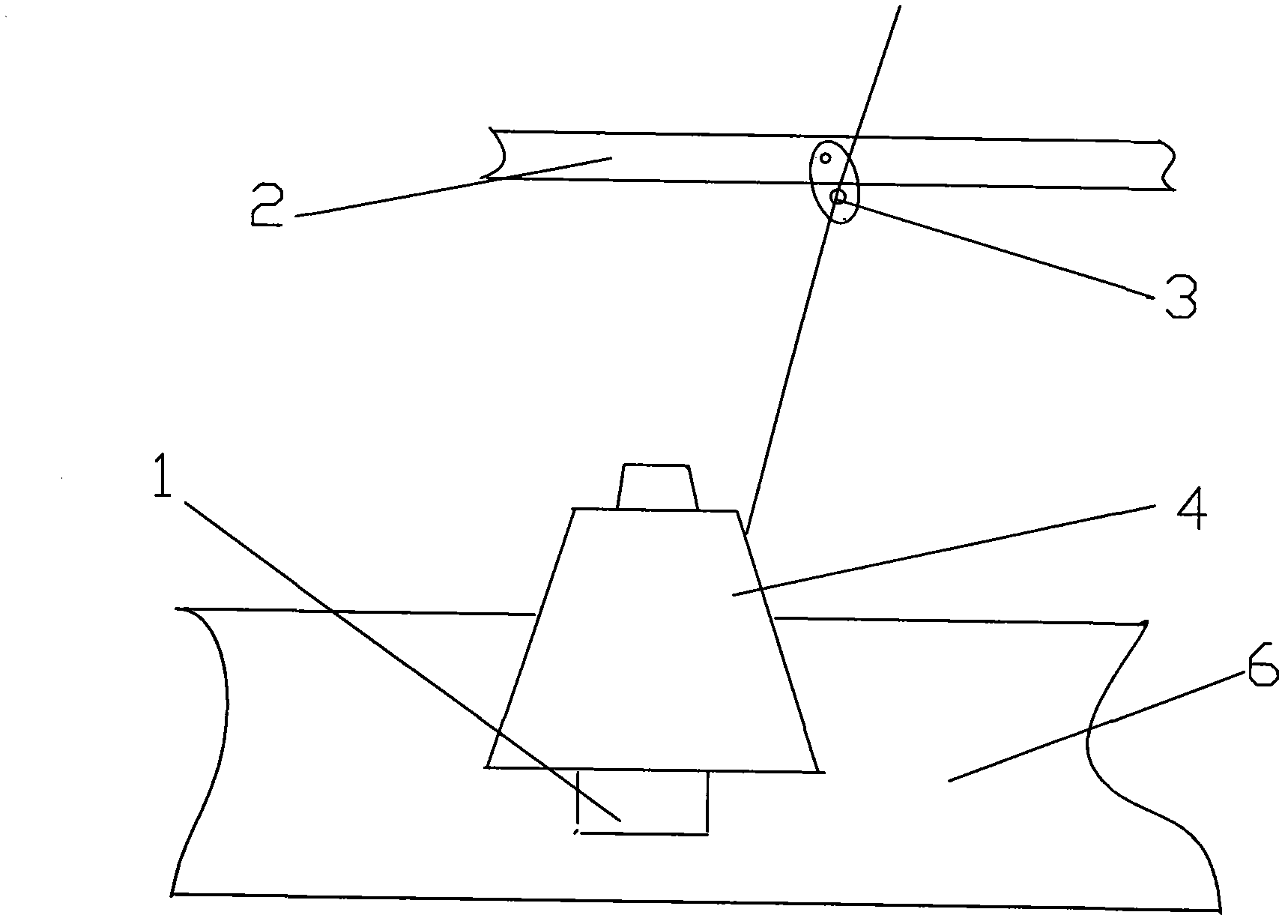

[0010] exist figure 2 In the prior art embodiment of the vertical unwinding device for the weft yarn of the rapier loom, the conical package yarn 4 is mounted on the weft storage rack support plate 6. Since the small end of the conical package yarn is on the top, the weft yarn passes through the yarn. The yarn drawing hole 3 on the frame 2 is connected to the weft feeder. When the unwinding speed of the yarn reaches 250-270M / mi, some short fibers of the yarn will fall off by friction when passing through the yarn drawing porcelain eye, and fall and gather on the upper part of the bobbin. With the increase of aggregated short fibers, under certain humidity conditions, it is very easy to entangle with the high-speed unwinding yarn, forming yarn defects and bringing them into the weft yarns, forming weft defects on the fabric surface.

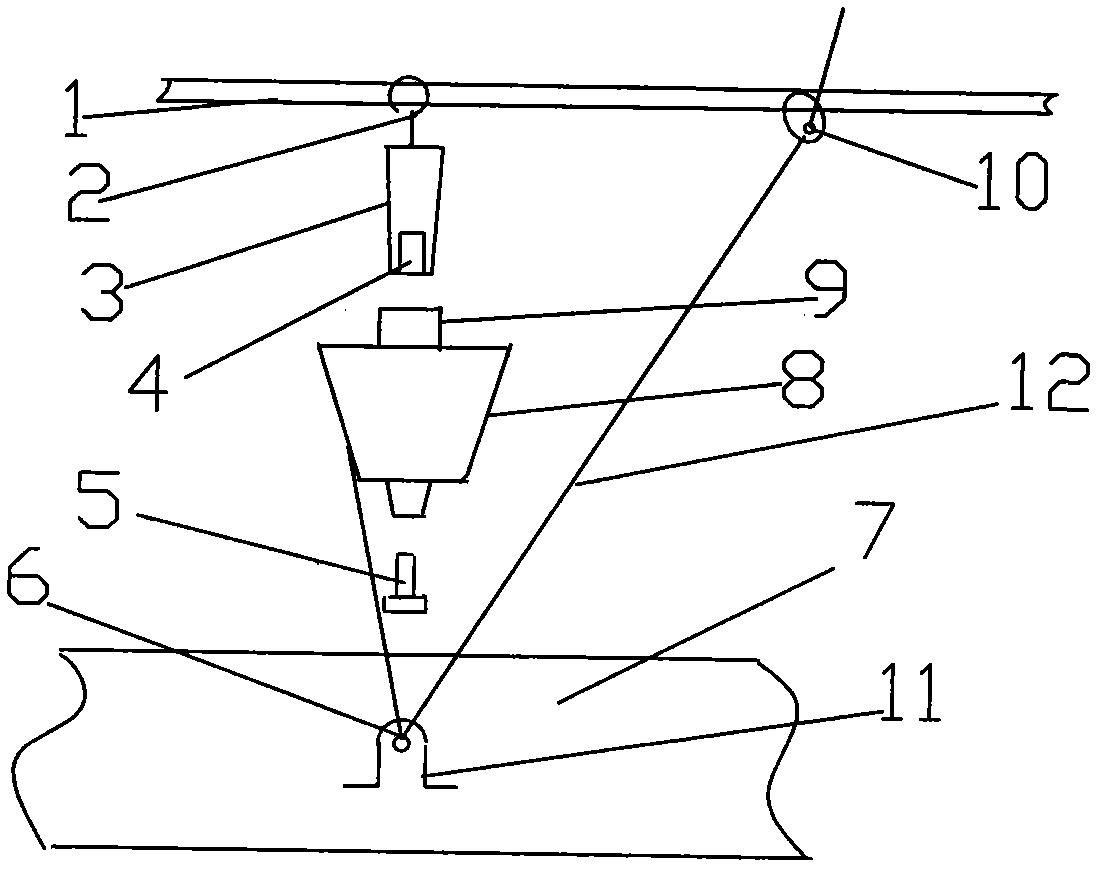

[0011] exist figure 1 In the embodiment of the present invention, the tapered rod 3 is equipped with a hook 2, the metal hook 2 is hung on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com