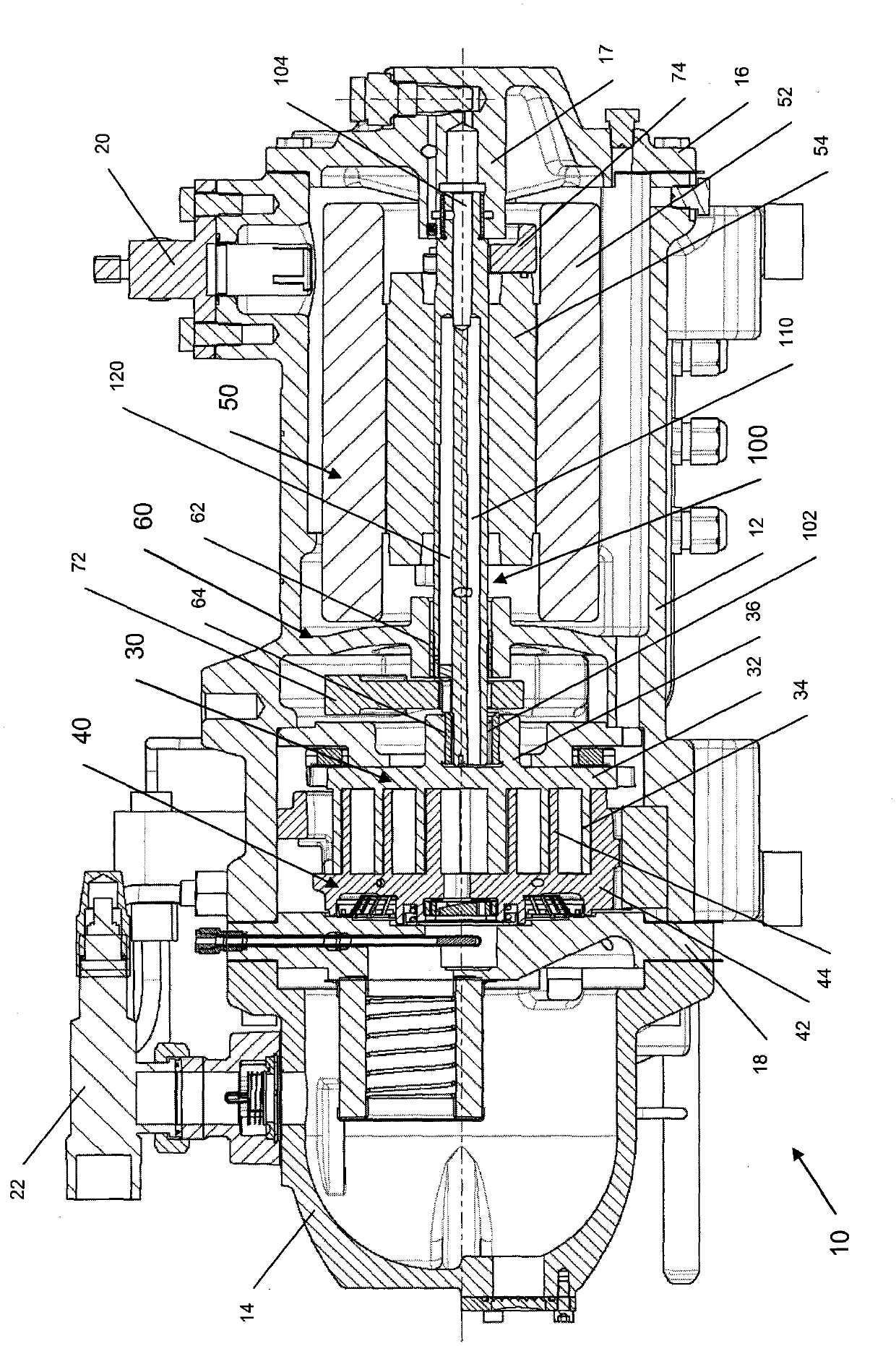

rotary compressor

A technology of rotary compressor and compression mechanism, which is applied in the direction of rotary piston/swing piston pump components, mechanical equipment, machines/engines, etc., which can solve the problems of damaged compressors, inequalities, etc., and achieve the effect of simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following description of preferred embodiments is exemplary only and in no way restricts the invention and its application or usage.

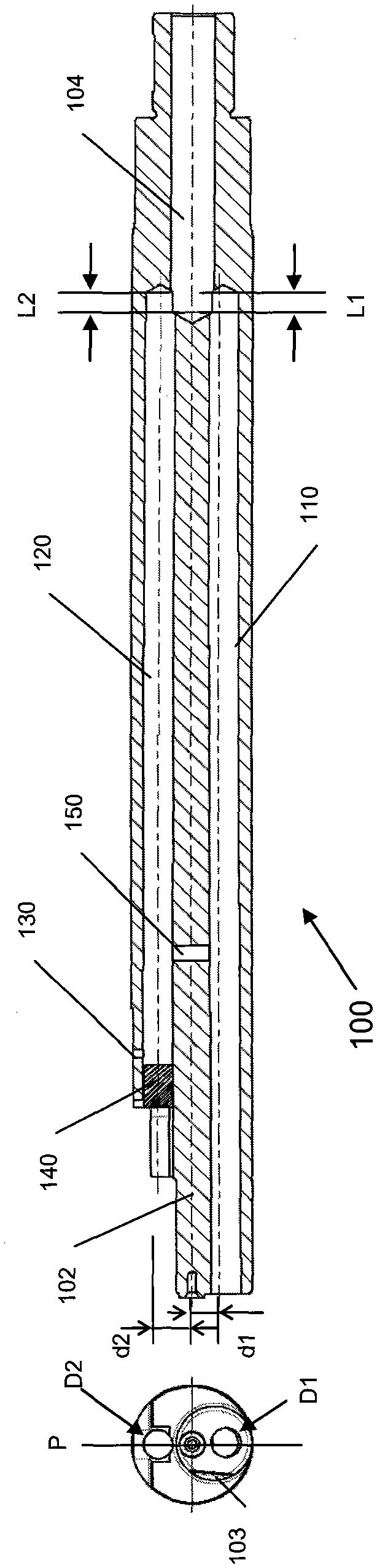

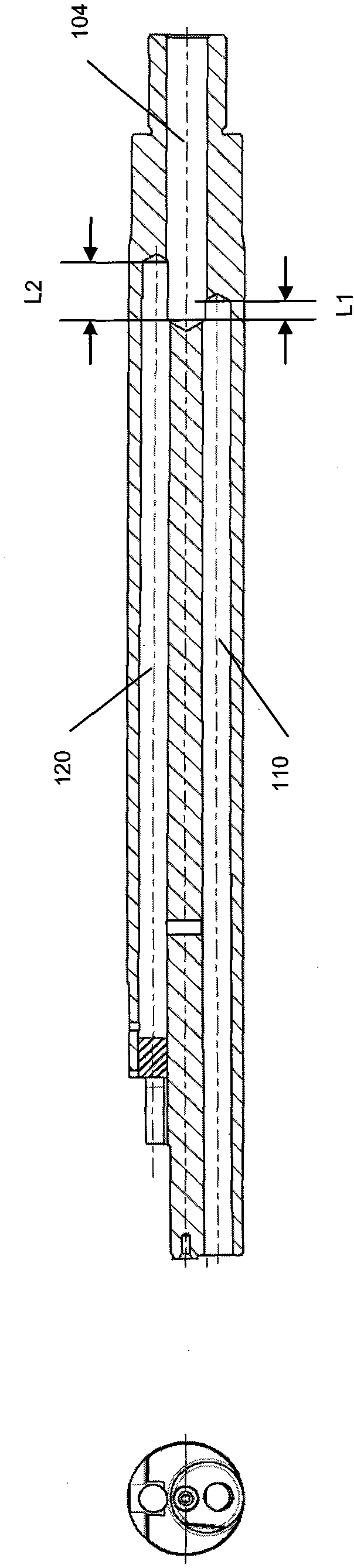

[0036] The inventors of the present invention found that in some vertical scroll compressors, in order to improve the lubricating oil supply to the main bearing, a transverse hole communicating with the eccentric hole is provided at a position of the rotating shaft corresponding to the main bearing. In this compressor configuration, lubricating oil can be supplied directly to the main bearing through the transverse bore and also directly to the rotary bearing through the eccentric bore extending to the top surface of the eccentric crankpin. Since the height of the transverse hole is lower than the top surface of the eccentric crank pin, lubricating oil can be more easily supplied to the main bearing. In the case of insufficient lubricant supply, the swing bearing will receive less lubricant than the main bearing, so the swing bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com