Heat carrier indirect heating type carbon capture calcining furnace

A heating type, carbon capture technology, applied in the field of boilers, can solve the problems of high investment and operating costs, and achieve high-purity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

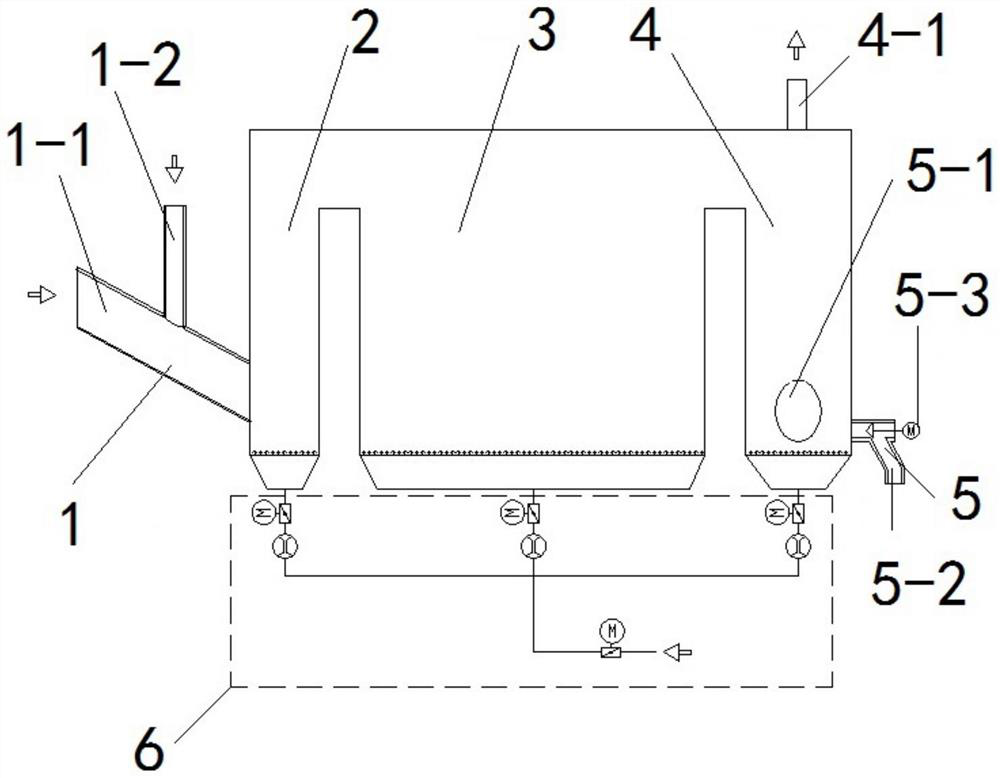

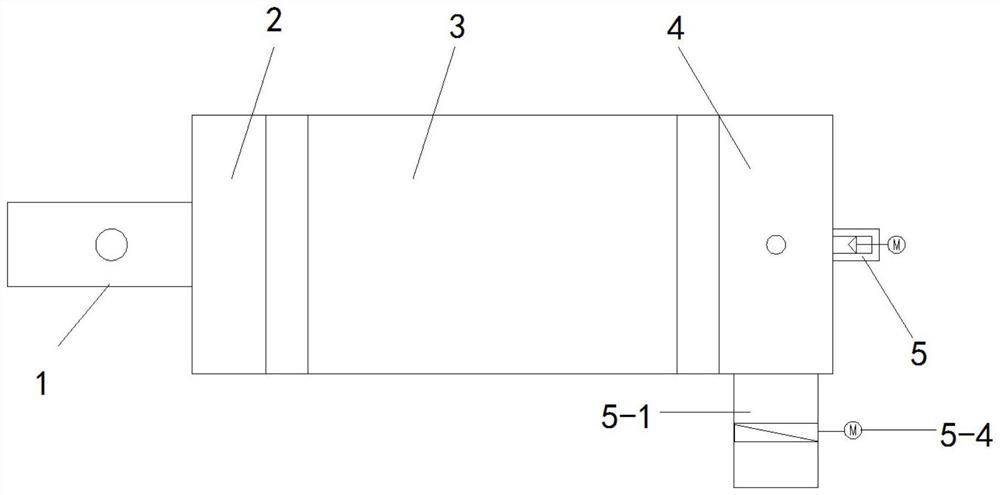

[0029] Embodiment 1: A heat carrier indirect heating carbon capture calciner, which includes an incoming material collection device 1, a premix chamber 2, a calcination reaction chamber 3, a distribution chamber 4, a discharge distribution device 5 and CO 2 Fluidized air system 6;

[0030] The incoming material collecting device 1, the premixing chamber 2, the calcining reaction chamber 3, the distribution chamber 4, and the discharging distribution device 5 are arranged in sequence from one end to the other end, and the premixing chamber 2, the calcining reaction chamber 3 and the distribution chamber 4 are all connected with the CO 2 The fluidized air system 6 is connected, and the incoming material collection device 1 is used for injecting heat carrier and carbon-carrying agent, and the heat carrier is a combustion heat source.

[0031] In this embodiment, after the carbon carrier and the heat carrier are mixed in the premixing chamber, they enter the calcination reaction ...

specific Embodiment approach 2

[0033] Specific embodiment 2: a heat carrier indirect heating type carbon capture calciner according to claim 1, one side of the upper end of the calcination reaction chamber 3 is connected to the premix chamber 2, and the other side of the upper end of the calcination reaction chamber 3 is connected The side is connected to the distribution chamber 4 .

[0034] Other embodiments are the same as the first embodiment.

specific Embodiment approach 3

[0035] Embodiment 3: A heat carrier indirect heating carbon capture calciner, the bottom of the premixing chamber 2, the bottom of the calcination reaction chamber 3 and the bottom of the distribution chamber 4 are all mixed with CO 2 The fluidized air system 6 is connected.

[0036] Other embodiments are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com