Bus section symmetric-convexity tapered roller and finish grinding method

A technology of tapered rollers and busbars, which is applied in the field of segmented symmetrical convex tapered rollers of busbars and final grinding, which can solve the problems of short service life of tapered rollers, high noise bearings, low bearing service life of bearings, etc., and achieve lower temperature Improvement of processing quality, vibration and noise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

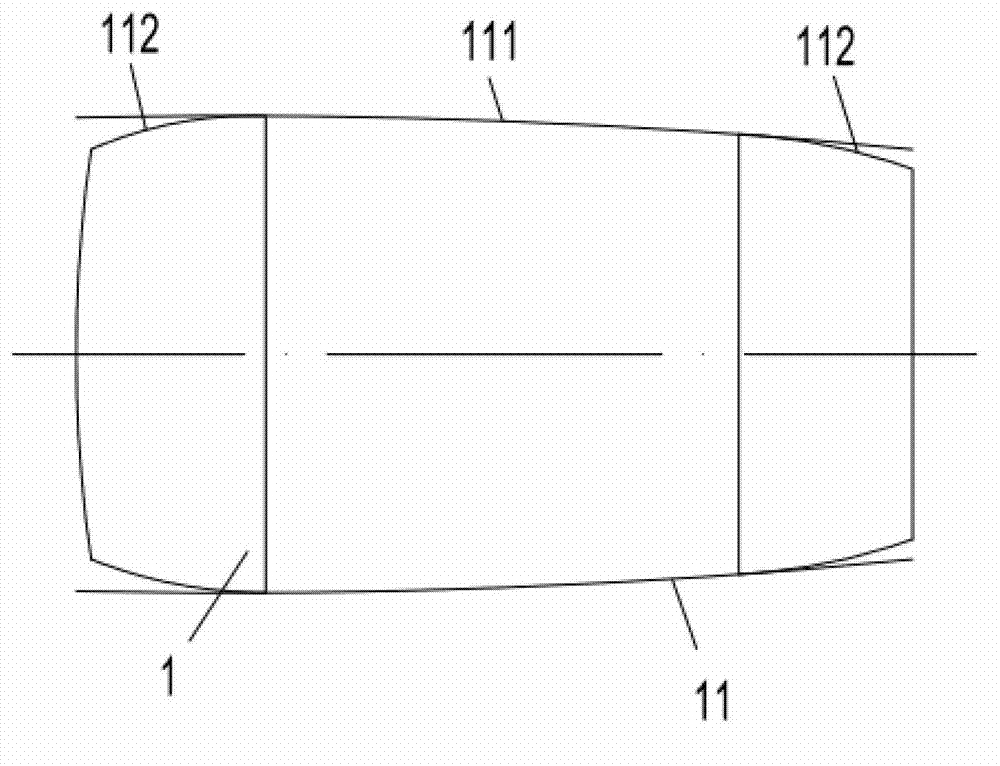

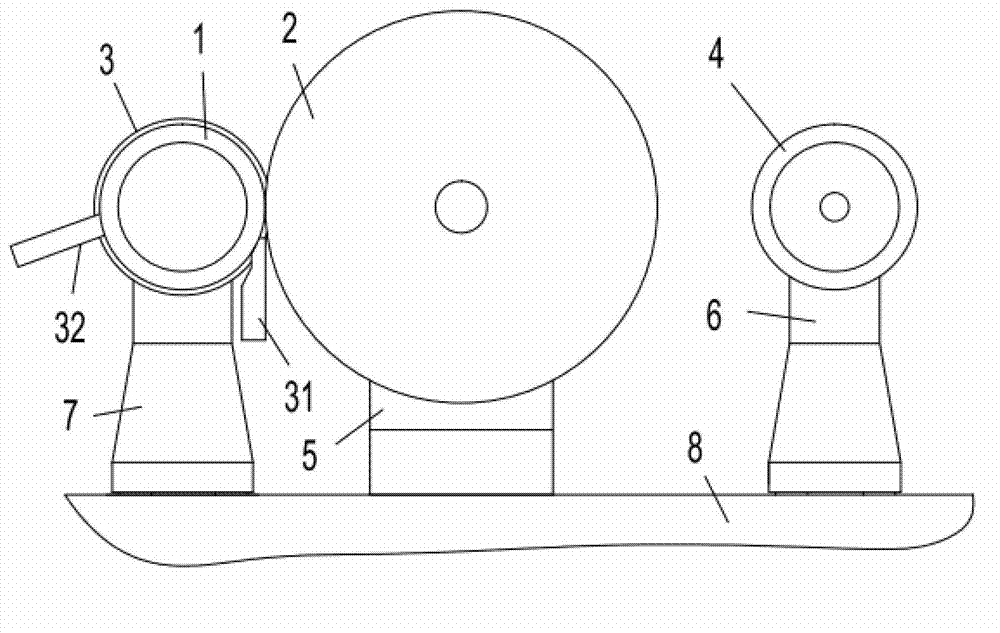

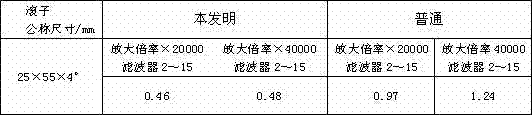

[0020] as attached figure 1 , attached figure 2 Shown: a tapered roller 1 with segmented symmetrical convexity on the busbar 1, the busbar 11 of the tapered roller 11 with the segmented symmetrical convexity on the busbar includes a central convex line 111 and two sections of end convex lines 112; The radius of curvature of the line 112 is smaller than the radius of curvature of the convex line 111; the two ends of the convex line 111 are smoothly connected to one end of a section of the convex line 112; the convex line 111 and the two sections of the convex line 112 Both are logarithmic curves or arc correction curves; the ratio of the projected lengths of the end convex line 112 and the central convex line 111 on the axis of the convex tapered roller 1 of the 11th section of the bus bar is 2:3 to 2: 7. In this embodiment, both ends of the convex line 111 are tange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com