Verifying device for gas drainage comprehensive parameter tester

A comprehensive parameter and gas drainage technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of cumbersome operation, low calibration efficiency, and various calibration instruments, and achieve the effect of simplifying the calibration process and improving the calibration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

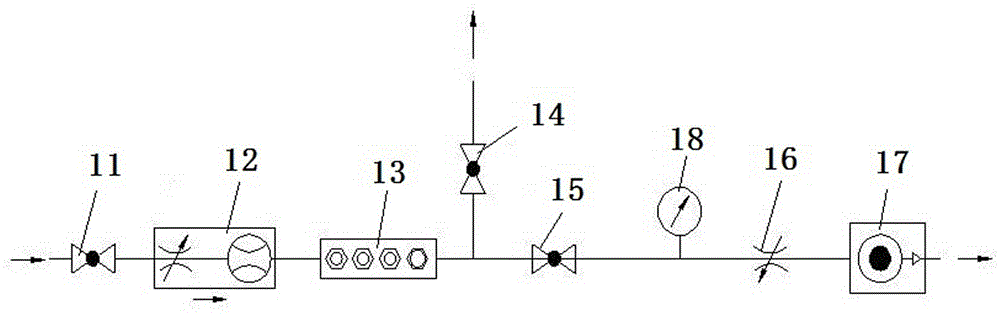

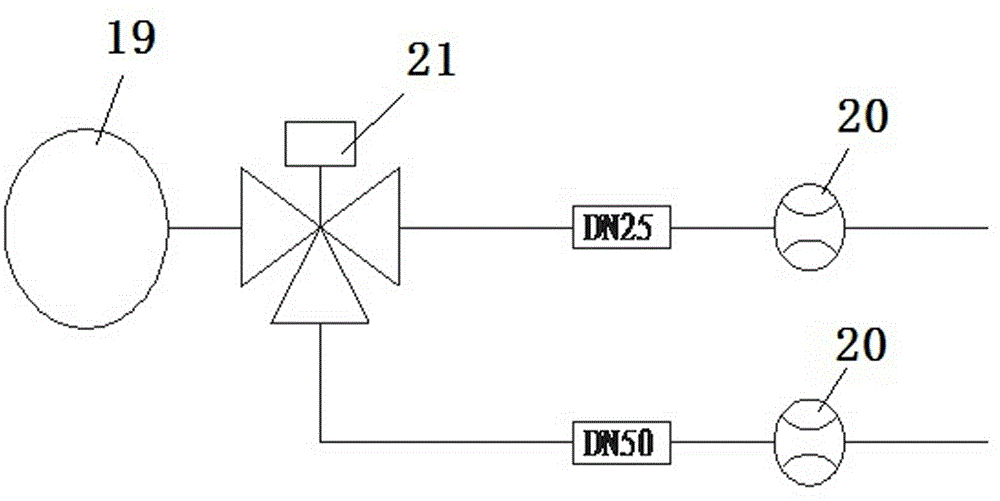

[0016] Embodiment 1 of the calibration device of the gas drainage comprehensive parameter measuring instrument of the present invention, as Figure 1-2 As shown, it includes the casing and the concentrated pressure verification part and the flow verification part set in the casing.

[0017] The concentrated pressure verification part includes the intake valve 11, the first regulating valve 12 and the socket seat 13 connected in series through pipelines. In this embodiment, the first regulating valve 12 is a regulating valve with a flow meter, and the socket seat 13 is used for It is connected with the corresponding gas drainage comprehensive parameter measuring instrument. The socket seat 13 has an air inlet, an air outlet and a socket for connecting with the gas drainage comprehensive parameter measuring instrument. The air inlet of the port seat 13 is connected, and the air outlet of the socket seat 13 leads to two branches through the pipeline, and the end of each branch is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com