Vibration and self noise monitoring system of fuel-powered unmanned submersible vehicle

A technology for unmanned submersibles and monitoring systems, applied to vibration measurement in fluids, measuring vibrations, instruments, etc., can solve the inconvenience of system upgrades and improvements, storage capacity expansion, data recording equipment volume and weight restrictions, and inconvenient labor Issues such as direct operation and intervention to achieve the effects of improved scalability, convenient debugging, and real-time observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0021] This embodiment provides a vibration and self-noise monitoring system applied to a fuel-powered unmanned submersible. The system can monitor the vibration and self-noise data of the fuel-powered unmanned submersible in real time, and is easy to debug and easy to use.

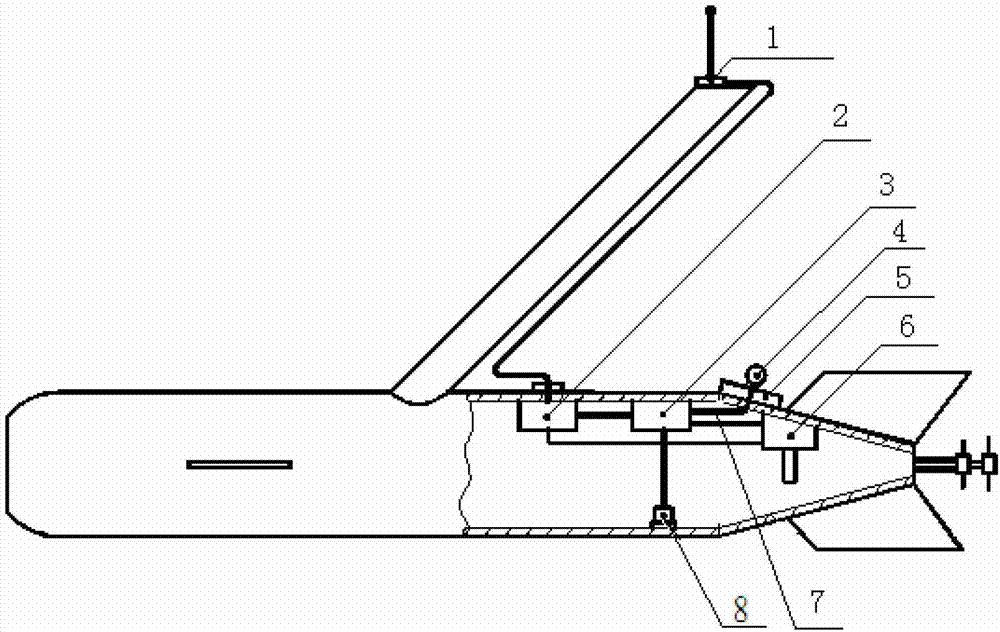

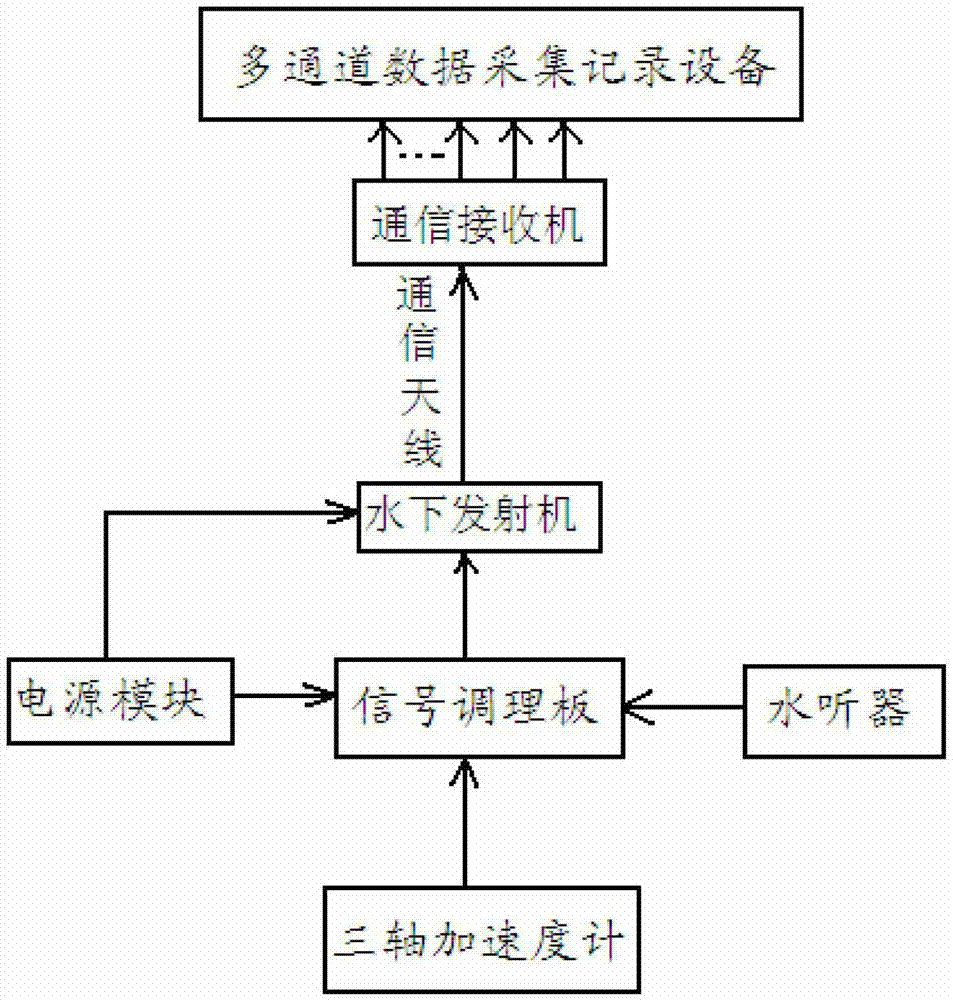

[0022] The structure of the system is as figure 1 As shown, it includes a wireless communication module, a signal conditioning board 3, a hydrophone 4, a hydrophone adapter mount 5, a power module 6, a cabin cable 7, and a three-axis accelerometer 8 and a multi-channel data acquisition recorder 9 . The wireless communication module includes a communication antenna 1, an underwater transmitter 2 and a communication receiver. The underwater transmitter 2 is located in the shell of the unmanned submersible, the communication receiver is located on the shore, and the communication betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com