Constant flow sampler and flow calibration method thereof

A flow sampling and flow rate technology, applied in testing/calibration devices, liquid/fluid solid measurement, instruments, etc., can solve the problems of loss of authenticity of samples, decrease of working condition flow rate, deviation from design value, etc., to achieve representativeness and authenticity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

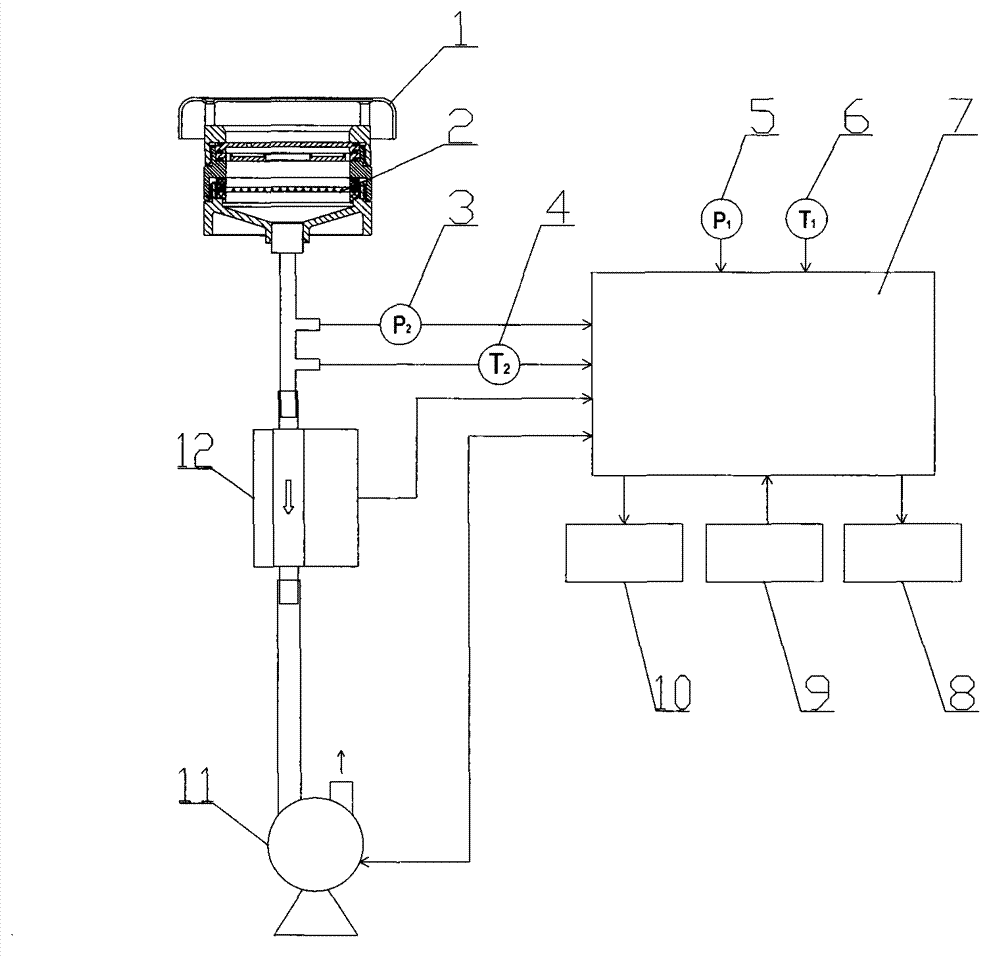

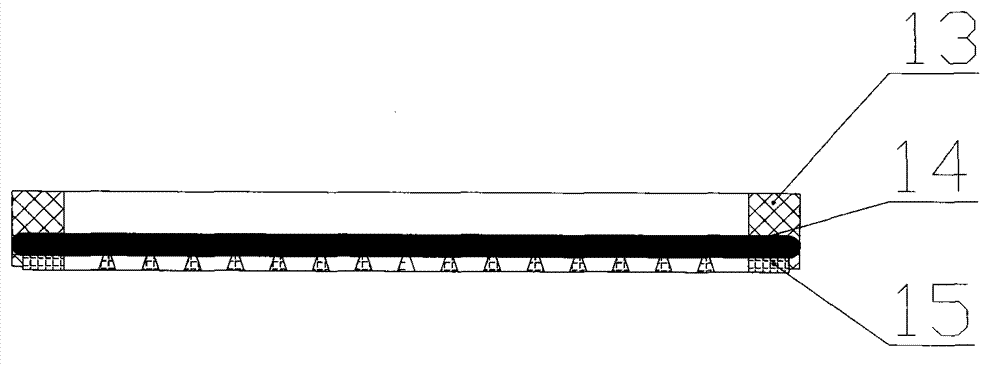

[0025] Example 1, see Figure 1-2 , this embodiment discloses a constant current sampler, which is composed of a cutter 1, a filter holder 2, a flow sensor 12, and an air pumping power 11, and also includes an ambient temperature sensor 6, an ambient pressure sensor 5, and a front temperature sensor 4 , pre-meter pressure sensor 3, single-chip microcomputer 7, display 10 and keyboard 9, printer 8;

[0026] Among them, the ambient temperature sensor and the ambient pressure sensor are electrically connected with the single-chip electromechanical device for measuring the ambient temperature and pressure values;

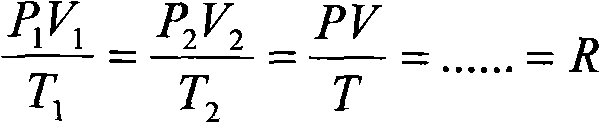

[0027] The cutter is located at the front end of the filter, the air outlet of the filter is connected to the air inlet of the flow sensor, and the air circuit between the air inlet of the flow sensor and the air outlet of the filter is installed with a single-chip electromechanical connection, used A pre-meter pressure sensor and a pre-meter temperature sensor for mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com