Control system and program for liquid chromatograph

A technology of liquid chromatograph and control equipment, applied in the field of control equipment and control program for liquid chromatograph

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

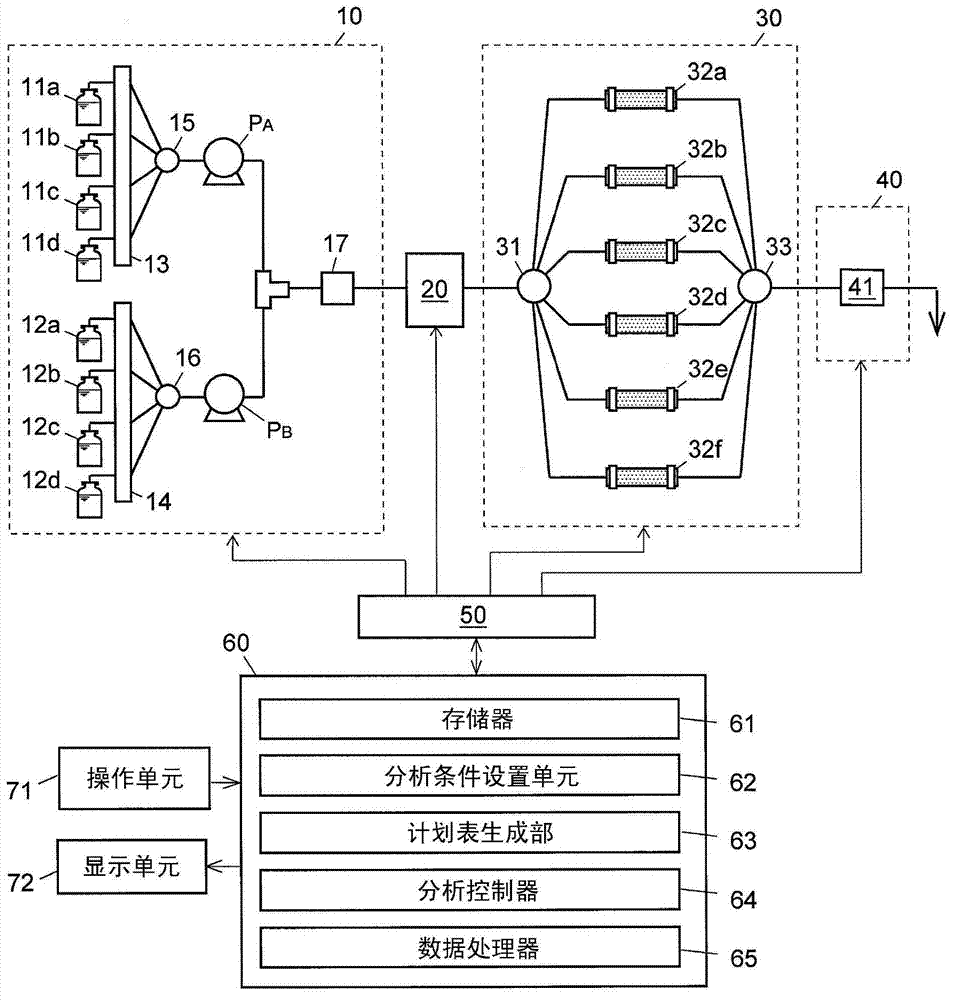

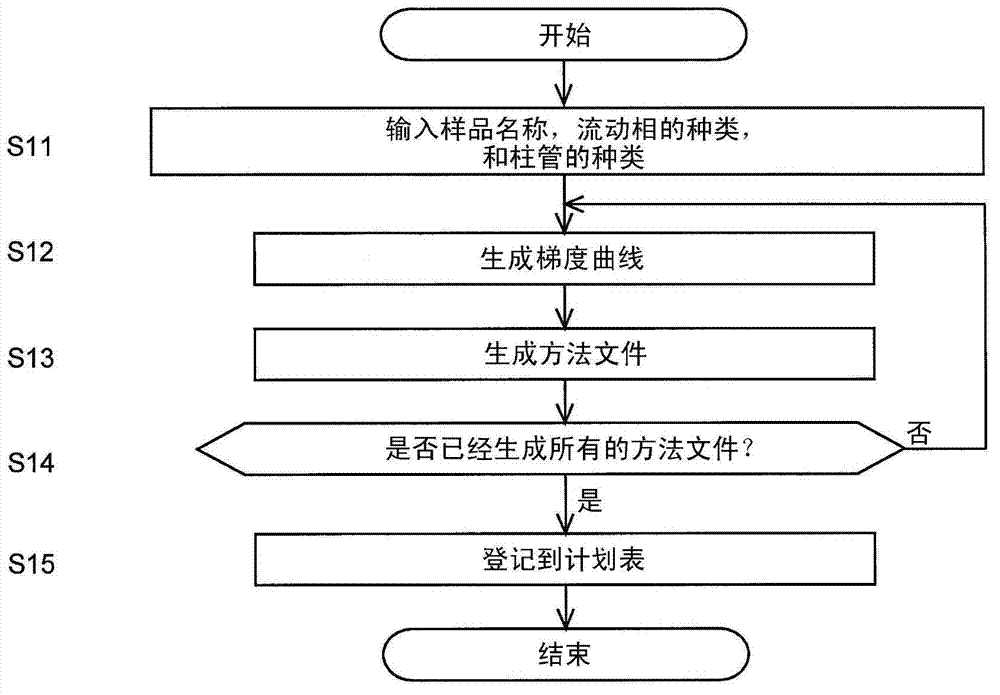

[0079] Will refer to Figure 1 to Figure 6 The control device for the liquid chromatograph according to the first embodiment of the present invention is described. According to the current embodiment, figure 1 It is a schematic configuration diagram of a liquid chromatograph with control equipment.

[0080] This liquid chromatograph includes: a liquid supply part 10; an autosampler 20; a column thermostat 30; a detection unit 40; a system controller 50 for controlling each of these units; A controller 60 that manages analysis operations and the detector analyzes and processes data obtained through the detector 40; an operating unit 71 composed of a keyboard and a mouse connected to the controller 60; a display unit composed of a display; and other units .

[0081] The liquid supply part 10 is mixed through the pump P A Pumped solvent A and pump P B Withdraw solvent B, and then supply the mixed solvent to the column tube. Four solvent containers are connected to each pump P throu...

no. 2 approach

[0102] Will refer to figure 2 with Figure 7 to Figure 14 The control device of the liquid chromatograph according to the second embodiment of the present invention is described.

[0103] The control device of this embodiment has the figure 1 The liquid chromatograph shown with this control device has the same structure. Therefore, the structural description is omitted. In this embodiment, the schedule generating section 63 and the analysis controller 64 cooperate and serve as the analysis controller and the preliminary liquid supply controller in the second aspect of the present invention described above. The data processor 65 corresponds to the analysis result storage unit and the automatic data file naming unit in the second aspect of the present invention described above.

[0104] The standard analysis operations in the single gradient analysis using the liquid chromatograph of the current embodiment (ie, the operations in sample introduction processing, gradient processing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com