Laminated inductor

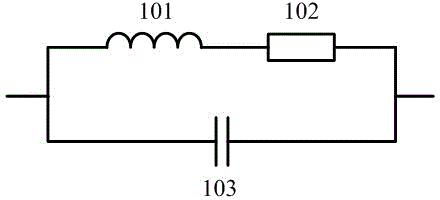

A technology of laminated inductor and laminated body, applied in the direction of inductors, fixed inductors, fixed signal inductors, etc., can solve the problems of side 202 leakage electrodes, increase of parasitic capacitance C, and inability to achieve high Q value of inductors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

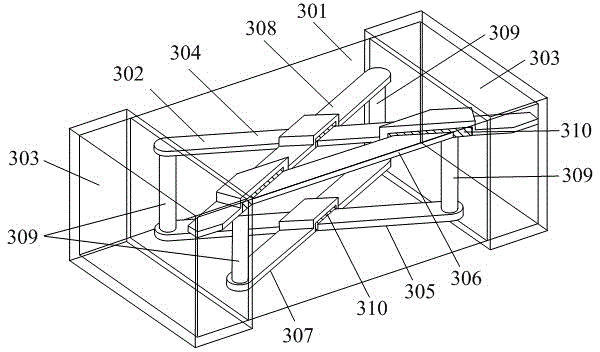

[0021] like image 3 As shown, it is a three-dimensional structure diagram of a laminated inductor according to this specific embodiment, including a laminated body 301, a coil electrode 302 and a pair of external electrodes 303, and a pair of external electrodes 303 are respectively arranged at both ends of the laminated body 301. It conducts with both lead-out ends of the coil electrode 302 .

[0022] like Figure 4 As shown, it is a schematic diagram of the exploded structure of the stacked body of the stacked inductor in this specific embodiment. The stacked body 301 includes an upper substrate 402 stacked in sequence, and multi-layer insulator layers 404, 4051-405m (in this specific embodiment m=3), 403 and the lower substrate 401 . Each insulator layer may be a ceramic body layer of ceramic material.

[0023] Wherein, the upper substrate 402 and the lower substrate 401 are also insulator layer structures, which are only used as substrates without printing conductive p...

specific Embodiment approach 2

[0036] The difference between this embodiment and Embodiment 1 is that in this embodiment, n=4, that is, the uppermost insulator layer has 4 upper plane electrodes, and the lowermost insulator layer has 3 lower plane electrodes. There are 6 through-hole electrodes in the middle, and the electrodes 304 and 308 in the upper plane electrode are not arranged along the diagonal, and the electrodes 305 and 307 in the lower plane electrode are not arranged along the diagonal, and each plane electrode of the same layer is Any form of cross setting is sufficient.

[0037] like Figure 5 As shown, it is a three-dimensional structure diagram of the laminated inductor in this specific embodiment, including a laminated body 301, a coil electrode 502 and a pair of external electrodes 303, and a pair of external electrodes 303 are respectively arranged at both ends of the laminated body 301. It conducts with both lead-out ends of the coil electrode 502 .

[0038] like Image 6 As shown, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap